LED flip chip packaging device and packaging process thereof

A technology for packaging devices and flip-chips, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of low error tolerance, difficulty in controlling the position of glue points, positioning deviation, etc., achieve strong antistatic ability, improve the gathering effect, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

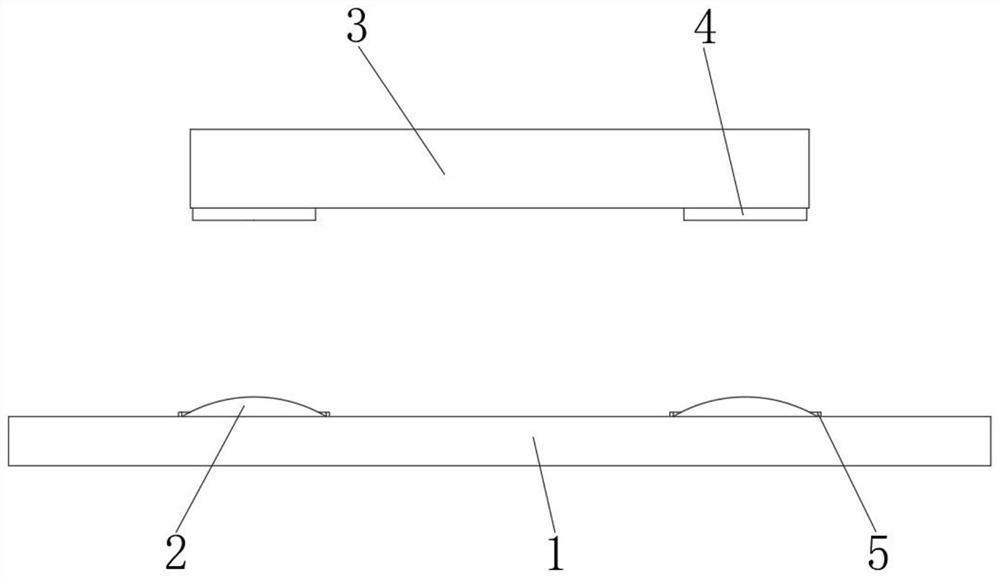

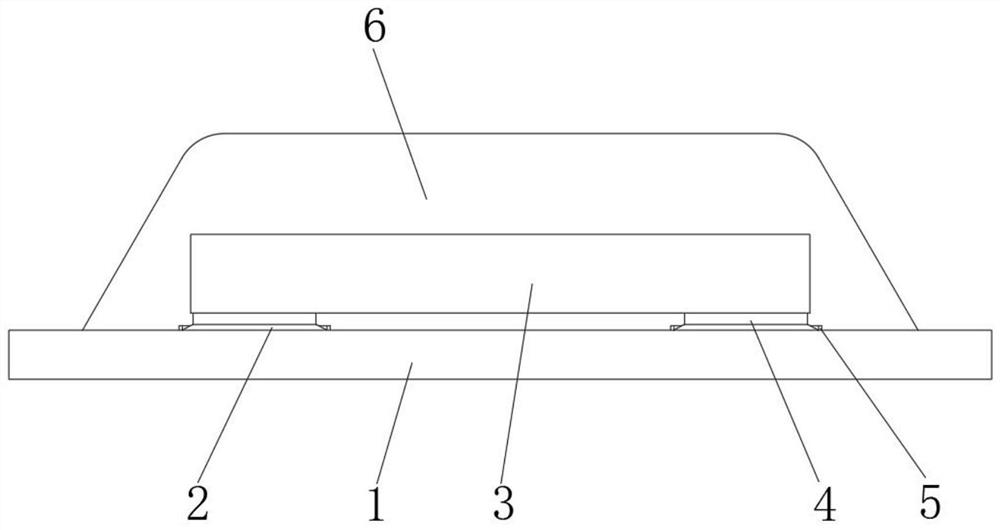

[0033] A kind of LED flip-chip packaging device, such as figure 1 , figure 2 As shown, it includes a substrate 1 and a chip 3; the substrate 1 is provided with copper foil, the copper foil is plated with 10u of silver, the top outer wall of the substrate 1 is provided with a limiting ring 5, and the top outer wall of the substrate 1 in the limiting ring 5 Tin spots 2 are soldered on the top; solder spots 4 are provided on the surface of the chip 3, and the solder spots 4 of the chip 3 are reflow-welded in the limiting ring 5 on the substrate 1 through the tin spots 2; the positions of the limiting ring 5 and the tin spots 2 and The quantity is adapted to the soldering point 4; the chip 3 is coated with an adhesive layer 6, and the adhesive layer 6 is completely wrapped around the chip 3 and the limit ring 5; in this embodiment, the chip 3 is set to pass through the soldering point 4 and the tin point 2 Reverse soldering on the substrate 1 does not require any baking or wire ...

Embodiment 2

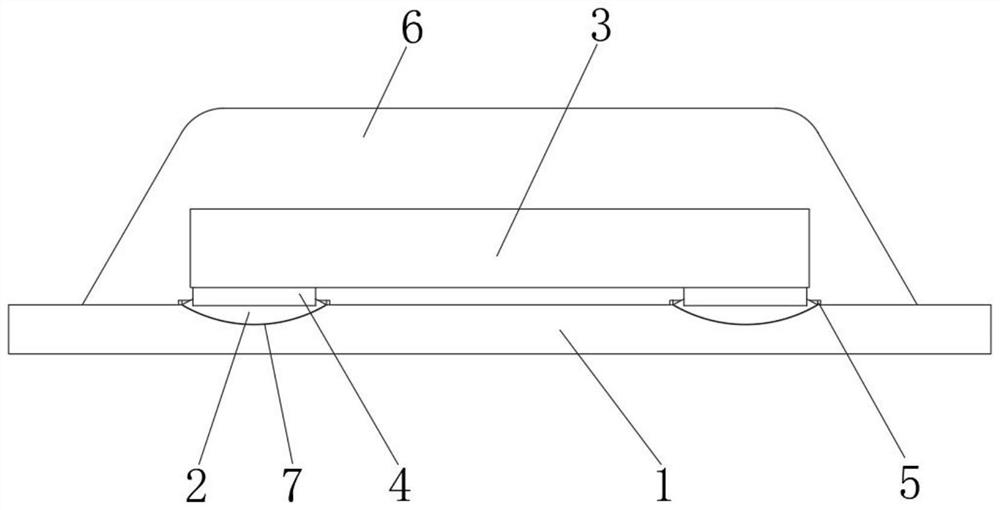

[0037] A kind of LED flip-chip packaging device, such as image 3 As shown, in order to further improve the welding firmness; this embodiment makes the following improvements on the basis of embodiment 1: the outer wall of the top of the substrate 1 is processed with a tin groove 7, and the tin point 2 is welded in the tin groove 7 on the substrate 1, The cross section of the tin bath 7 is an arc-shaped structure; by setting the tin bath 7, it can benefit the substrate 1 to eat tin, and improve the gathering effect of the tin spot 2, further avoiding the leakage of the tin spot 2, and ensuring the welding quality.

[0038] In order to improve reliability, such as image 3 As shown, the maximum diameter of the tin bath 7 is larger than the diameter of the solder joint 4 .

Embodiment 3

[0040] A kind of LED flip-chip packaging device, such as Figure 4 As shown, in order to improve the tightness of the adhesive layer 6; this embodiment makes the following improvements on the basis of embodiment 2: the outer wall of the top of the substrate 1 is processed with a glue groove 8, and the glue groove 8 is located outside the chip 3 and the limit ring 5 , the edge of the glue layer 6 is completely filled inside the glue groove 8; by setting the glue groove 8, the firmness of the connection between the edge of the glue layer 6 and the substrate 1 can be improved, thereby improving the adhesive layer 6 for the chip 3, etc. The sealing performance of the structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com