Method for representing internal stress of TATB-based PBX under force-heat effect

A technology of thermal action and internal stress, applied in the direction of applying stable tension/pressure to test material strength, using wave/particle radiation for material analysis, measuring devices, etc., can solve the problems of complex response mechanism and weak effect of polycrystalline system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

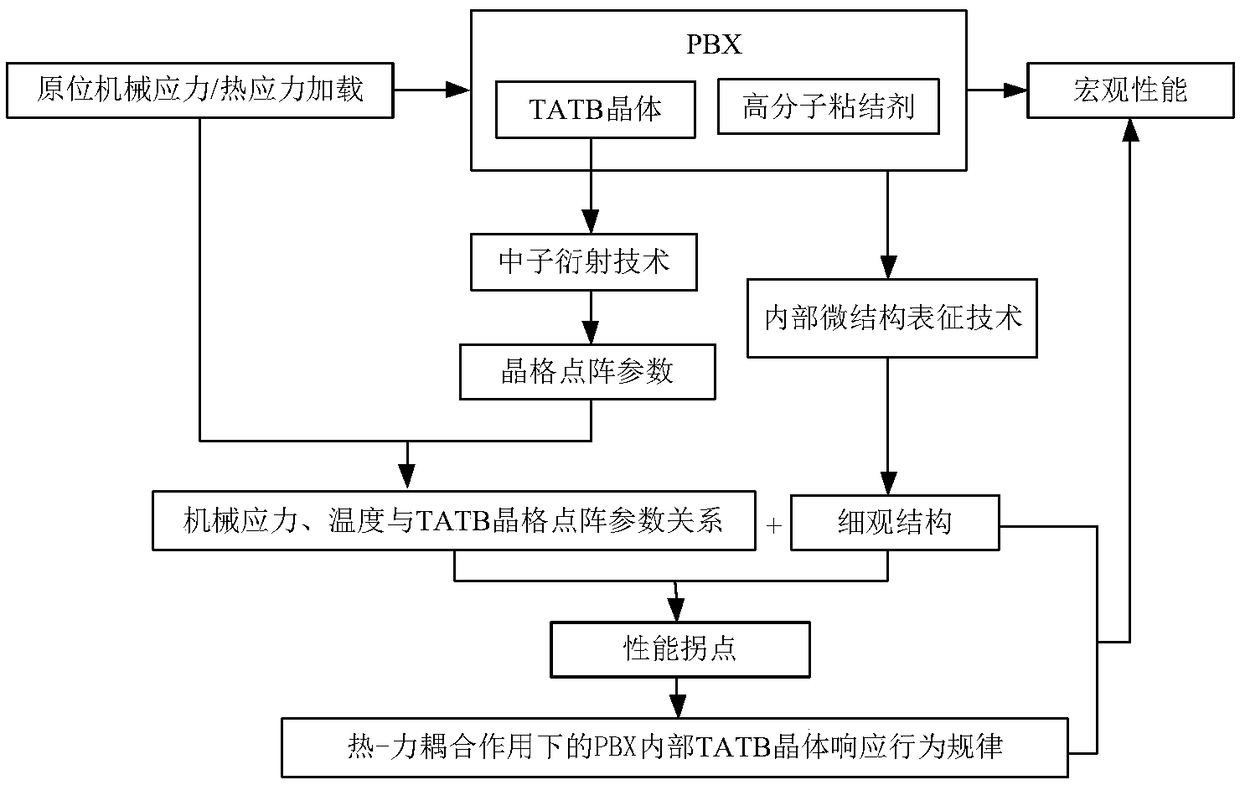

[0046] as attached figure 1 As shown, the present invention provides a method for characterizing TATB-based PBX internal stress under a force-thermal effect, comprising the steps of:

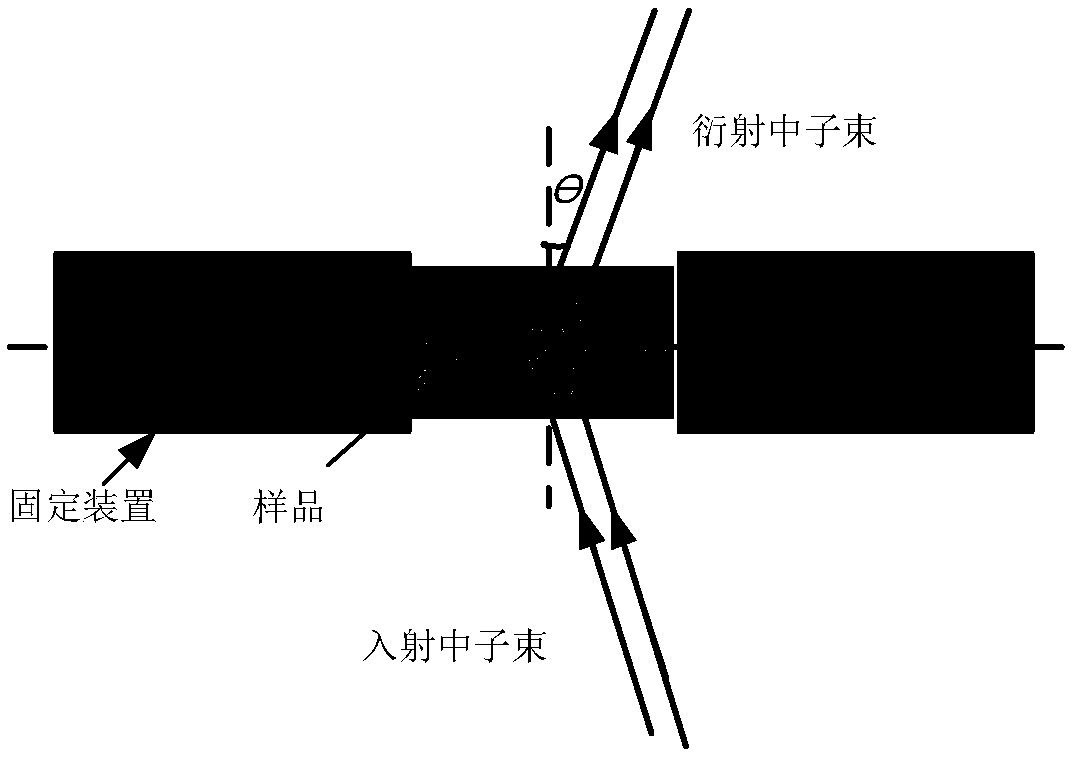

[0047] Carry out in-situ mechanical stress / thermal stress loading on PBX, use neutron diffraction technology to obtain the lattice lattice parameters of TATB crystal, and obtain the relationship between mechanical stress, temperature and TATB lattice lattice parameters;

[0048] At the same time, use internal microstructure characterization technology to obtain the mesostructure of PBX;

[0049] The inflection point of PBX performance is obtained through the relationship between mechanical stress, temperature and TATB lattice parameters and the mesostructure, and finally the response behavior law of TATB crystal inside PBX under the action of thermal-mechanical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com