Ultrasonic probe coupling assembly and ultrasonic probe mechanism

A technology of ultrasonic probe and coupling parts, which is applied in the directions of ultrasonic/sonic/infrasonic diagnosis, ultrasonic/sonic/infrasonic Permian technology, ultrasonic/sonic/infrasonic image/data processing, etc. It can solve the problem of solid-state coupling patches and probes Problems such as poor fit, troublesome use of solid-state coupling patches, and discomfort of gel-like coupling agents, etc., to achieve stable and effective transmission, good fit, and good assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

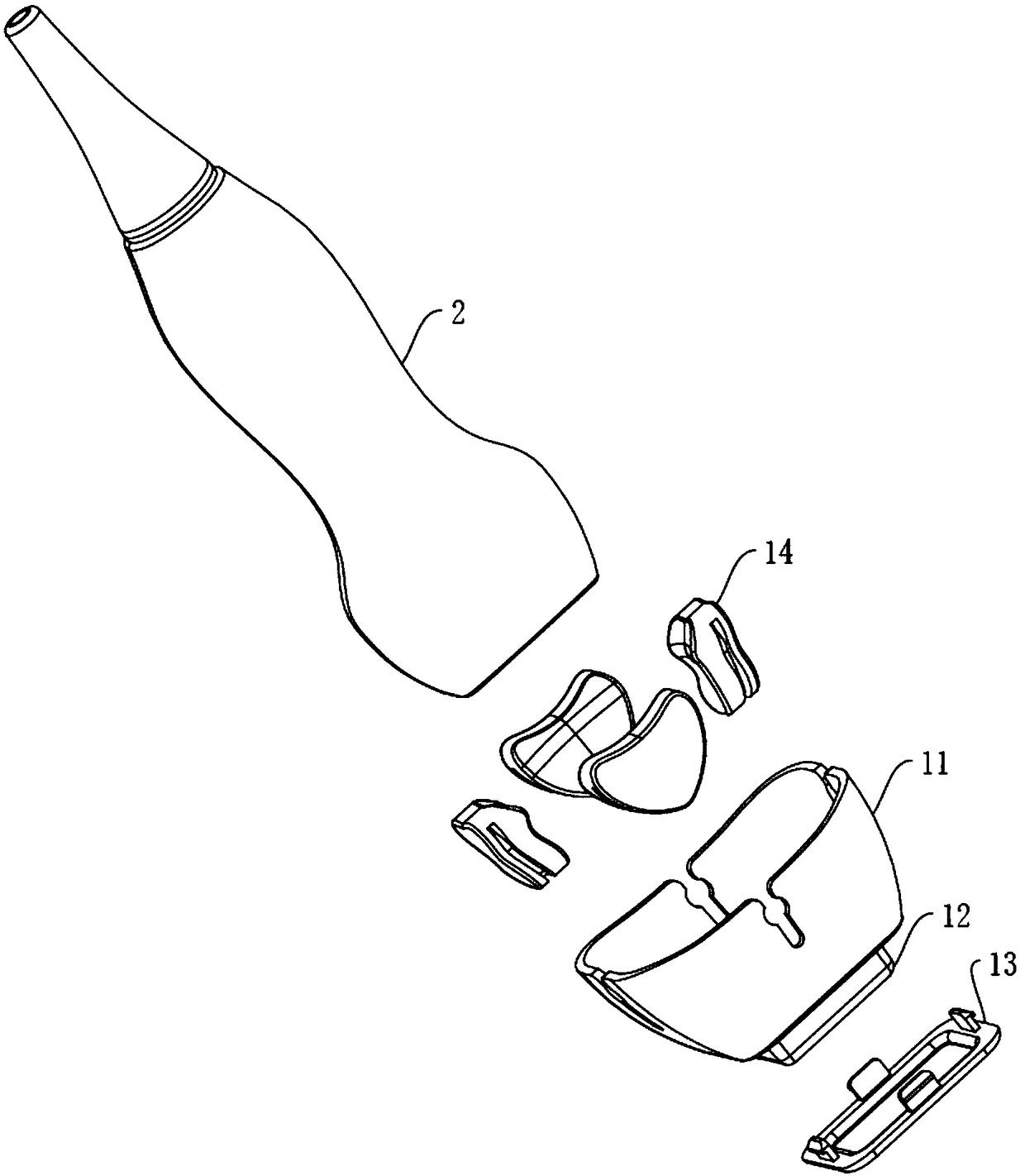

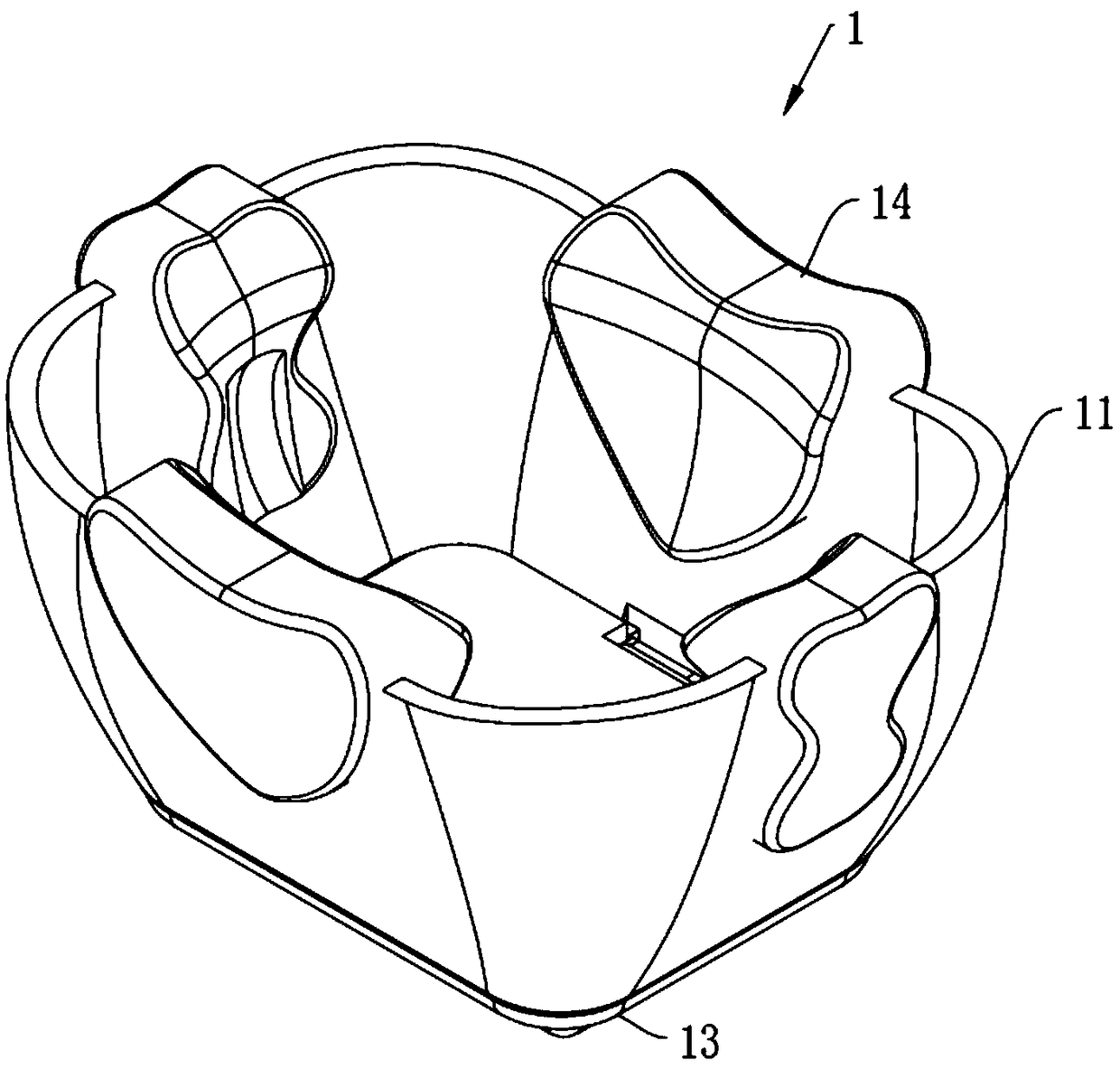

[0044] In this embodiment, the solid coupling part 12 is fixed in the probe ferrule 11 by injection molding. The solid coupling 12 is a solid coupling gel. At the beginning of injection molding, the coupling gel can flow, and the coupling gel forms a joint force with the probe ferrule 11 while solidifying, thereby being fixed in the probe ferrule 11 to form a solid state. Coupling 12.

[0045] Please also refer to Figure 3 to Figure 5 , the solid-state coupling 12 is molded on the probe ferrule 11 by injection molding, which saves the assembly of the solid-state coupling 12 on the probe ferrule 11 and effectively avoids damage to the solid-state coupling 12 when assembling the solid-state coupling 12 Pollution, due to the soft feature of the solid coupling 12, it can also effectively overcome the damage to the solid coupling 12 during assembly, and because the solid coupling 12 is easily deformed during assembly, it is easy to cause the assembly of the solid coupling 12. In...

Embodiment 2

[0071] Please also refer to Figure 8 to Figure 10 The difference between this embodiment and Embodiment 1 is that in this embodiment, the solid coupling 12 includes a plastic part 12a and a solid coupling part 12b, and the plastic part 12a is embedded in the solid coupling part 12b so that the solid coupling 12 forms as one. The plastic part 12 a becomes the annular protrusion of the solid coupling part 12 , and the solid coupling part 12 is fixed in the probe ferrule 11 through the plastic part 12 a. By embedding the plastic part 12a in the solid coupling part 12b, the strength of the connection structure of the solid coupling part 12 is enhanced and the solid coupling part 12 is firmly fixed on the probe ferrule 11 .

[0072] The plastic part 12a is directly molded in the solid coupling part 12b, such as Figure 10 As shown, in order to clearly reflect the structure of the plastic part 12a, the plastic part 12a is separated from the solid coupling part 12b. The solid cou...

Embodiment 3

[0080] The difference between this embodiment and Embodiment 1 is that in this embodiment, the solid coupling part 12 and the probe ferrule 11 are separated, and the solid coupling part 12 is formed by coupling gel injection molding to form interconnected protrusions. The lifting part 122 and the fixing part 121 , the pressing part 13 fixes the solid coupling part 12 on the probe ferrule 11 by pressing the fixing part 121 on the probe ferrule 11 .

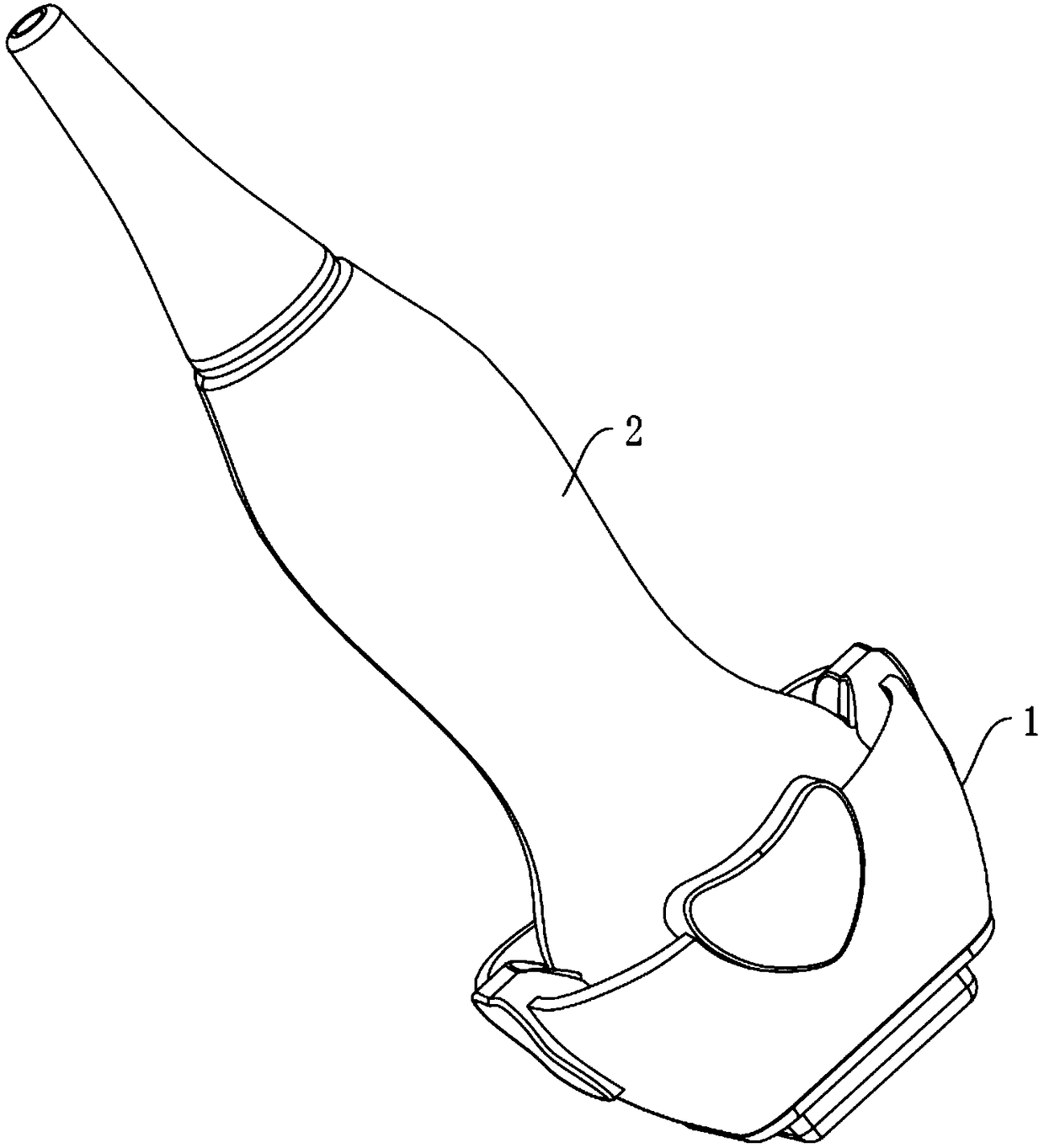

[0081] As mentioned above, the ultrasonic probe coupling assembly 1 and the ultrasonic probe 2 constitute the ultrasonic probe mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com