Semidry-method desulfurization system

A semi-dry desulfurization and denitrification technology, applied in the field of desulfurization, can solve the problems of large water consumption and achieve the effects of reducing water consumption, saving resources and reducing layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

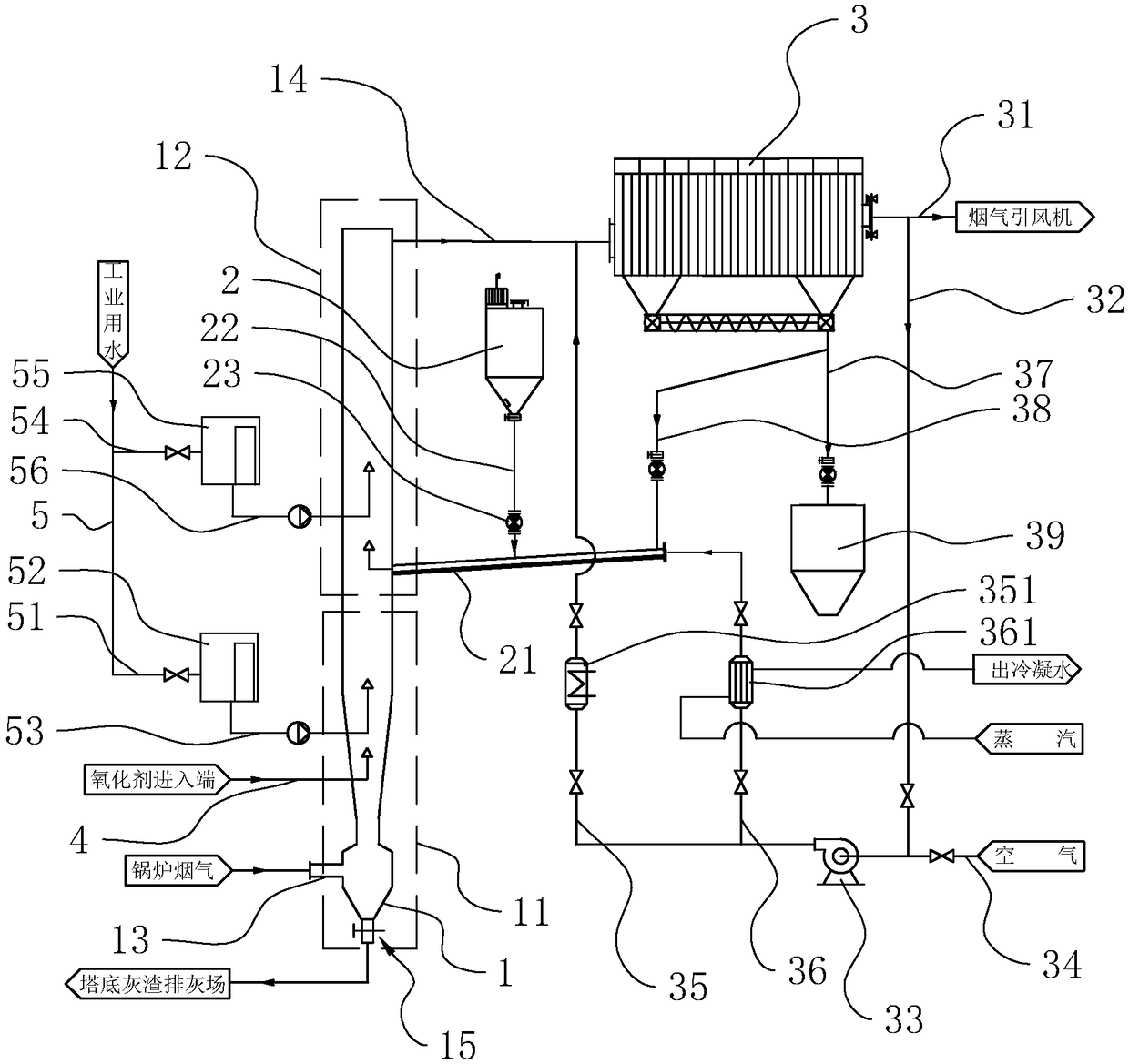

[0033] Example 1: refer to figure 1 , which is a semi-dry desulfurization system disclosed in the present invention, including a vertically arranged reaction tower 1 , a dust collector 3 , a powder storage bin 2 , and an ash bin 39 .

[0034] An inlet pipe 13 is communicated with the peripheral wall of the lower end of the reaction tower 1, and the flue gas to be purified can enter the reaction tower 1 from the inlet pipe 13; the lower end of the reaction tower 1 is provided with an opening for ash discharge, and an ash discharge valve is provided at the opening 15. The ash discharged from the lower end of the reaction tower 1 can be transported to the ash disposal field. A gas conduit 14 is connected to the peripheral wall at the top of the reaction tower 1 .

[0035] The reaction tower 1 includes a desulfurization reaction zone 12 and a denitration reaction zone 11 , and the flue gas passes through the denitration reaction zone 11 and the desulfurization reaction zone 12 in...

Embodiment 2

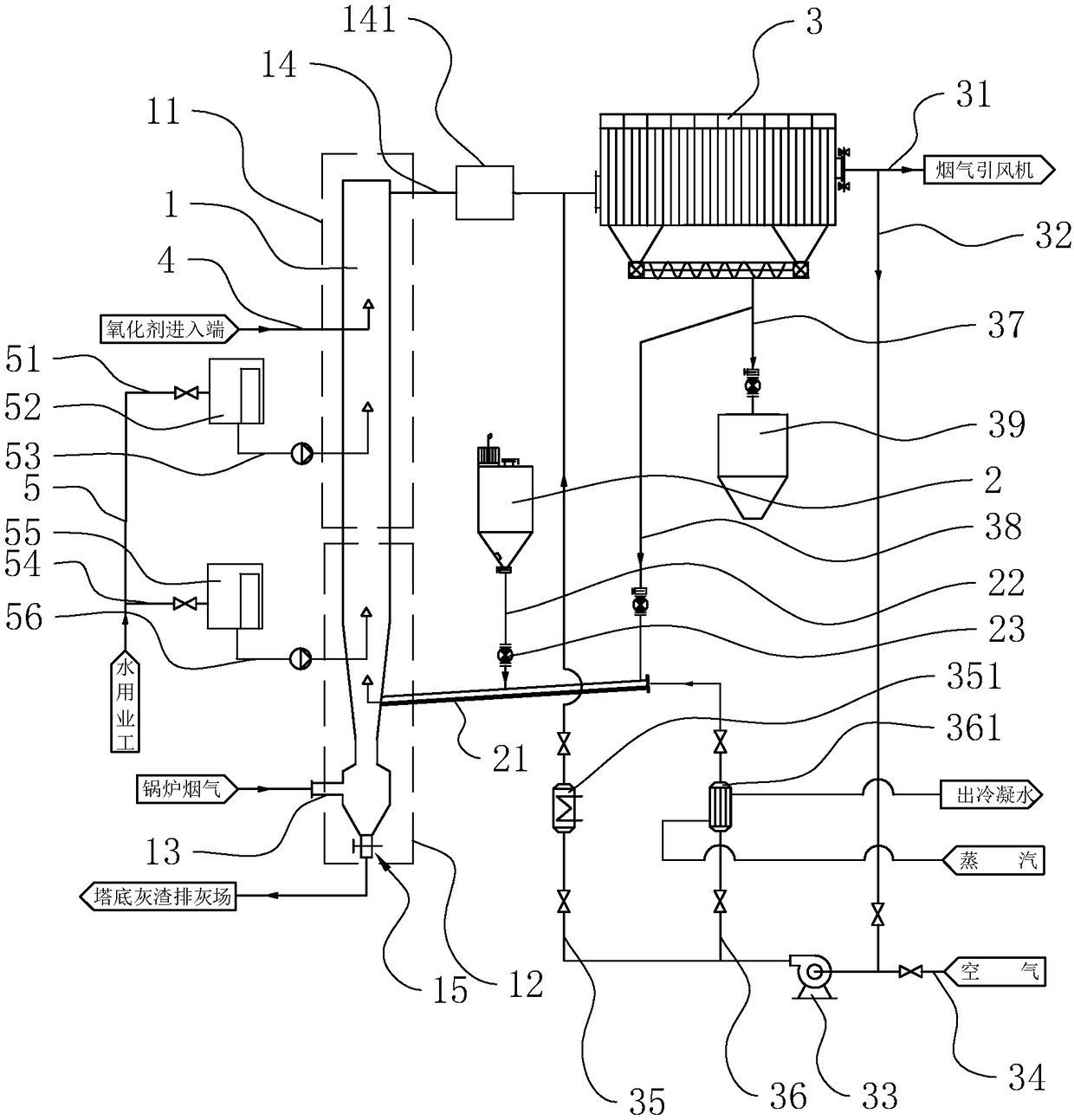

[0051] Embodiment 2: refer to figure 2 , which is a semi-dry desulfurization system disclosed in the present invention, which is different from the first embodiment in that the positions of the desulfurization reaction zone 12 and the denitration reaction zone 11 are exchanged, and a first heating device is installed on the gas conduit 14 141, but does not have a temperature control circuit.

[0052] Wherein, the first heating device 141 can be a hot air circulating electric heater, and the air duct 14 can be divided into a front section and a rear section, the front section is connected between the reaction tower 1 and the first heating device 141, and the rear section is connected to the first heating device 141 and dust collector 3.

[0053] The implementation principle of this embodiment is as follows: the flue gas passes through the desulfurization reaction zone 12, the denitration reaction zone 11, and the dust collector 3 in sequence. 2 reaction, SO 2 can eventually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com