Application of a sacrificial material to microstructure 3D light curing printing

A sacrificial material and 3D technology, applied in the field of 3D printing, can solve the problems of manual inefficiency, expensive, harsh tools, etc., and achieve the effect of optimized application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

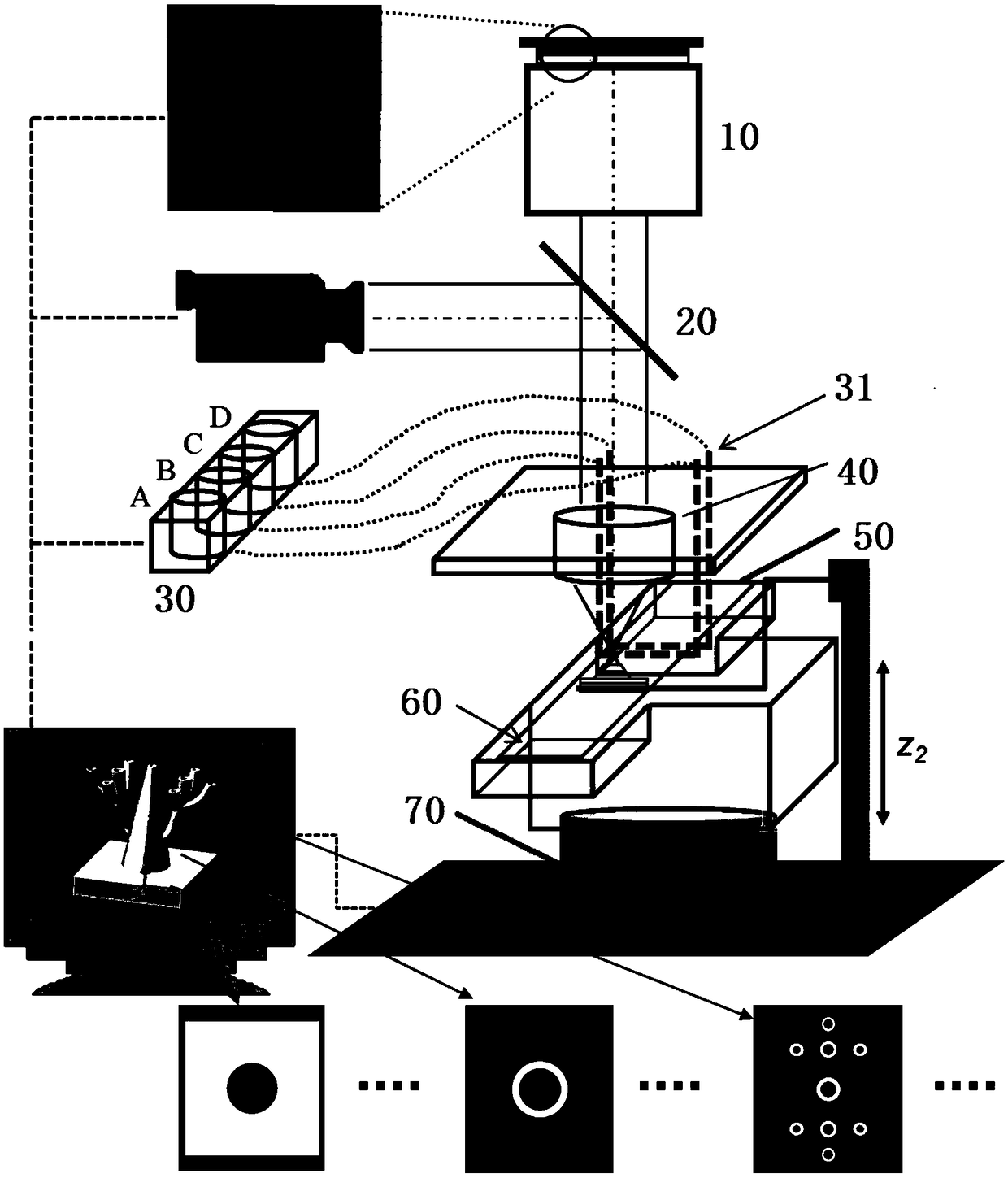

[0033] Such as figure 1 As shown, the multi-material micro-stereolithography system includes: an optical machine 10 , an electron (radiation) beam splitter 20 , a detergent 31 , a resin delivery 30 , a projection lens 40 , a scraper 50 , a film 60 and a container 70 .

Embodiment 2

[0035] A printing method using sacrificial materials in microstructure 3D photo-curing printing, comprising the following steps:

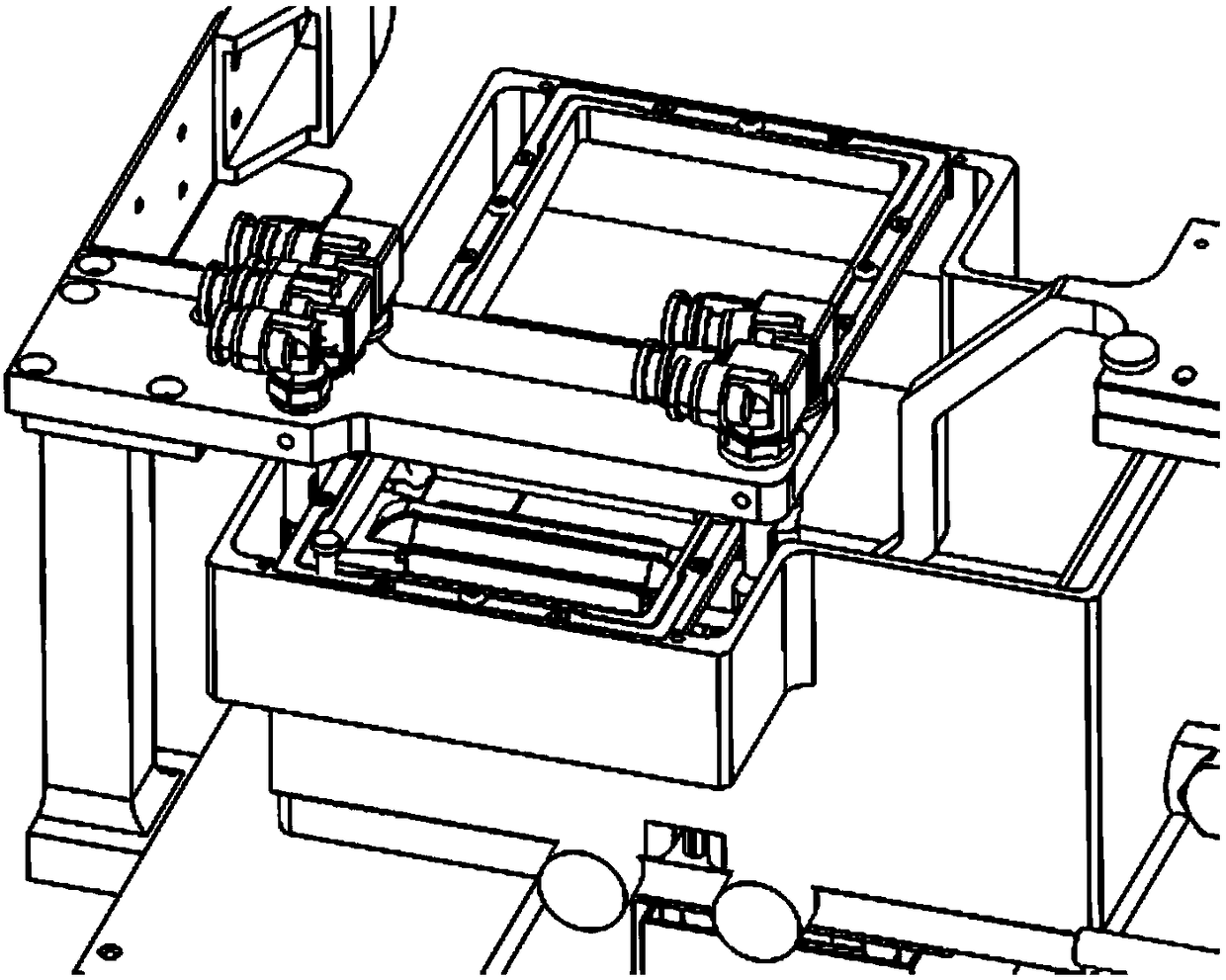

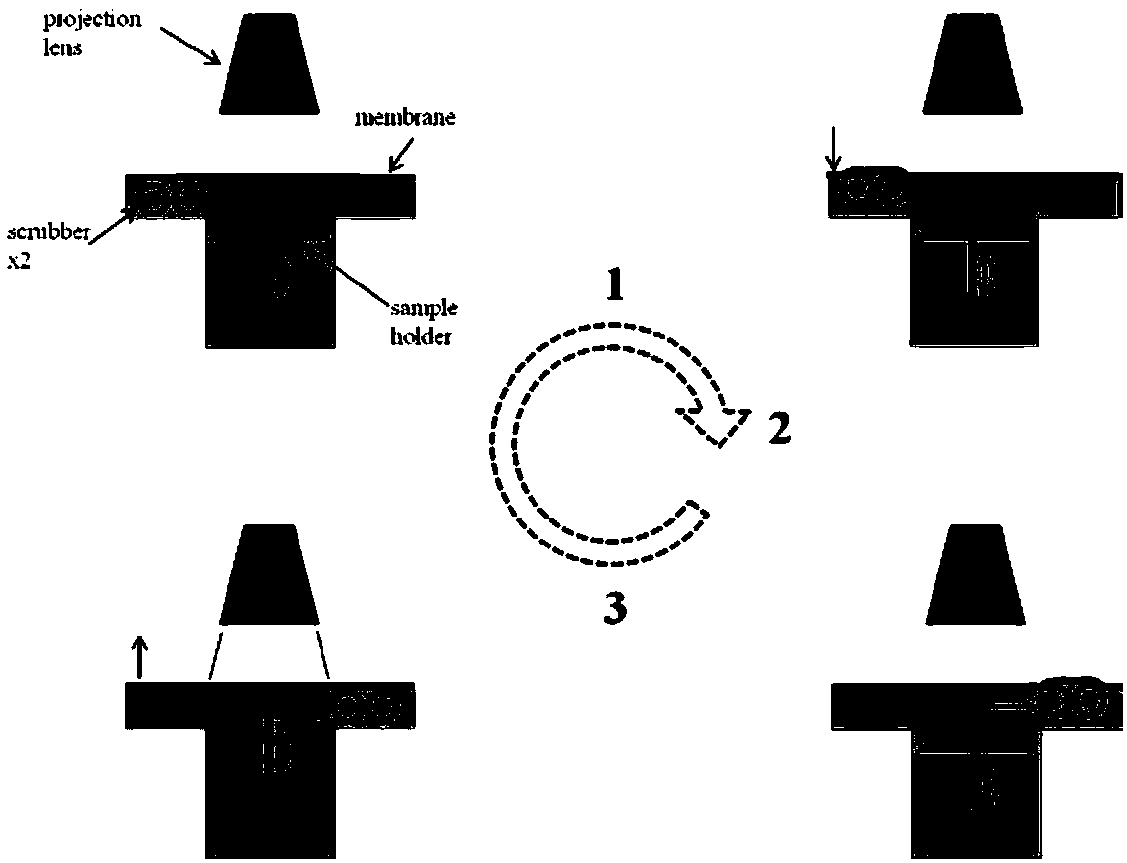

[0036] A projection lens projects the image on the DLP onto the lower surface of the film where the resin contacts, where the resin monomers react photochemically to cross-link into a solid. The material of the membrane here can be PDMS, PFA or other transparent films with a thickness ranging from 25 microns to 100 microns. The system has two parallel scrapers ( figure 2 ), to scrape off the resin, scrape the top film 0.5mm deep. Two resins are attached to each spatula. When working, the scraper that goes ahead scrapes off the old resin, and the scraper that goes behind applies resin backwards, as shown in Figure (3). In MCSL, there are two cases of resin switching (Figure 4). One is to switch resin between printing layers, one resin is printed on another resin, and after the scraper coats the new resin on the film, the sample is moved to the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com