Powder accelerator used for sprayed concrete and prepared from red mud and preparation method thereof

A technology of sprayed concrete and quick-setting agent, which is applied in the field of building materials, can solve the problems of insufficient utilization and occupation of red mud, achieve economic and environmental benefits of energy saving and emission reduction, reduce manufacturing costs, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

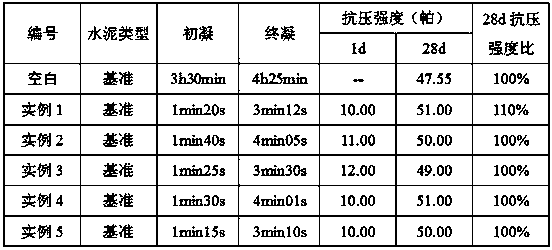

Examples

Embodiment 1

[0020] A powder quick-setting agent for shotcrete prepared from red mud

[0021] The powder accelerator is composed of 70% by mass of masterbatch and 30% of red mud, wherein the masterbatch is composed of 34% by mass of red mud, 26% of soda ash, 30% of gypsum and 10% of coal gangue.

[0022] A preparation method of powder quick-setting agent for shotcrete with red mud, comprising the following steps:

[0023] (1) Compatibility into masterbatch; according to mass percentage, 34% red mud, 26% soda ash, 30% gypsum and 10% coal gangue are compatible into masterbatch;

[0024] (2) Masterbatch treatment: The well-compatible masterbatch is ground and sieved through a 300-mesh sieve, and the sieve residue is <12%;

[0025] (3) Preparation of quick-setting agent: Prepare red mud with a water content lower than 1.3%, and mix 70% of masterbatch and 30% of red mud according to mass percentage to obtain powder quick-setting agent. Among them, the prepared powder accelerator has an initia...

Embodiment 2

[0027] A powder quick-setting agent for shotcrete prepared from red mud

[0028] The powder accelerator is composed of 67% by mass of masterbatch and 33% of red mud, wherein the masterbatch is composed of 29% by mass of red mud, 25% of soda ash, 34% of gypsum and 12% of coal gangue.

[0029] A preparation method of powder quick-setting agent for shotcrete with red mud, comprising the following steps:

[0030] (1) Compatibility into a masterbatch; according to the mass percentage, 29% of red mud, 25% of soda ash, 34% of gypsum and 12% of coal gangue are compatible into a masterbatch;

[0031] (2) Masterbatch treatment: The well-compatible masterbatch is ground and sieved through a 300-mesh sieve, and the sieve residue is <12%;

[0032] (3) Preparation of quick-setting agent: Prepare red mud with a water content of less than 1.3%, and fully mix 67% of masterbatch and 33% of red mud according to the mass percentage to obtain a powder quick-setting agent. Among them, the prepare...

Embodiment 3

[0034] A powder quick-setting agent for shotcrete prepared from red mud

[0035] The powder accelerator is composed of 65% by mass of masterbatch and 35% of red mud, wherein the masterbatch is composed of 26% by mass of red mud, 24% of soda ash, 35% of gypsum and 15% of coal gangue.

[0036] A preparation method of powder quick-setting agent for shotcrete with red mud, comprising the following steps:

[0037] (1) Compatibility into masterbatch; according to the mass percentage, 26% of red mud, 24% of soda ash, 35% of gypsum and 15% of coal gangue are compatible into masterbatch;

[0038] (2) Masterbatch treatment: The well-compatible masterbatch is ground and sieved through a 300-mesh sieve, and the sieve residue is <12%;

[0039] (3) Preparation of quick-setting agent: Prepare red mud with a water content of less than 1.3%, and fully mix 65% of masterbatch and 35% of red mud according to the mass percentage to obtain a powder quick-setting agent. Among them, the prepared po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com