Aqueous single-component organic zinc-rich coating and preparation method and application thereof

A one-component, zinc-rich technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve inconvenient construction, poor storage stability of one-component organic zinc-rich coatings, and early corrosion resistance of organic zinc-rich coatings Insufficient and other problems, to achieve the effect of good early corrosion resistance and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

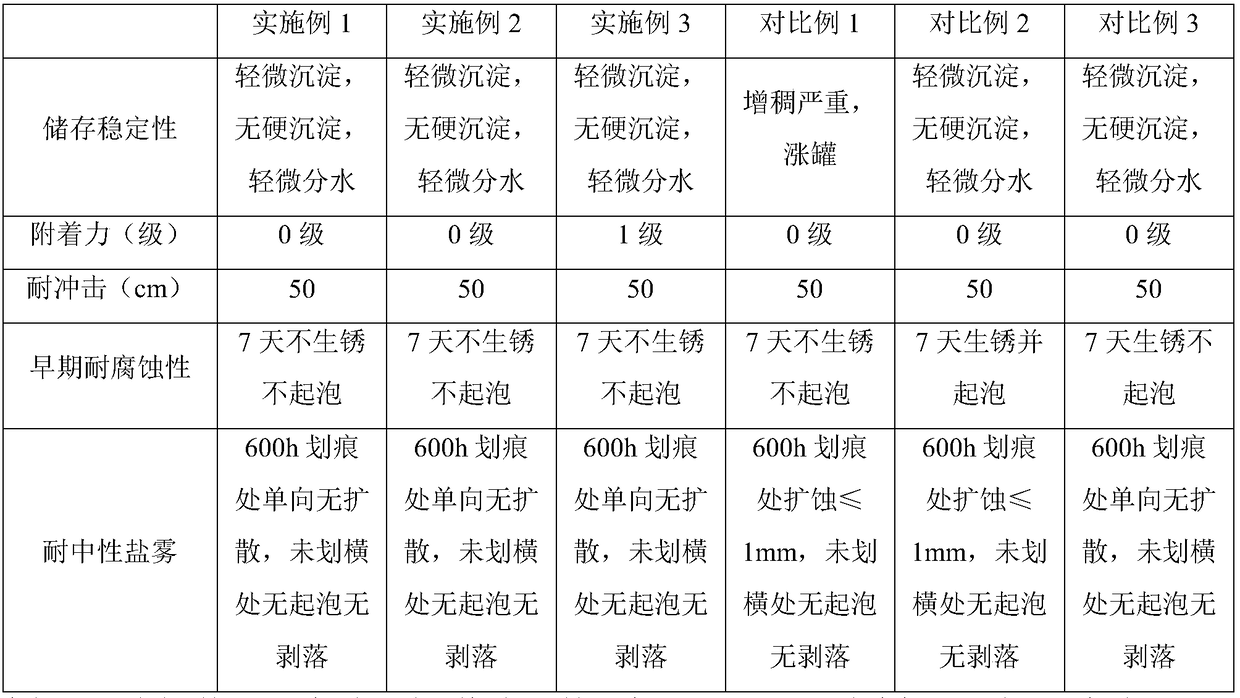

Examples

Embodiment 1

[0051] A water-based one-component organic zinc-rich coating, the components are as follows:

[0052] 15 parts of water-based one-component epoxy resin emulsion, 6 parts of propylene glycol methyl ether, 1 part of bentonite, 0.5 parts of Tech-6208 dispersant, 1 part of fumed silica, 80 parts of rare earth modified zinc powder, and 0.3 parts of silicone defoamer 2 parts, 2 parts of sulfur-containing high-efficiency corrosion inhibitor, 10 parts of water.

[0053] Preparation:

[0054] S1. Add 6 parts of propylene glycol methyl ether, 0.3 parts of wetting and dispersing agent, 1 part of bentonite, 0.3 parts of silicone defoamer, 1 part of fumed silica, some water, and stir at high speed (1500-2000r / min) in the tank 10-20 minutes;

[0055] S2. Continue to add 15 parts of water-based epoxy emulsion to the tank, stir at medium speed (1000-1200r / min) for 5-10 minutes, and mix well;

[0056] S3. Then add 80 parts of modified zinc powder, pass cooling water, and stir at high speed (1...

Embodiment 2

[0059] A water-based one-component organic zinc-rich coating, the components are as follows:

[0060] 10 parts of water-based one-component epoxy resin emulsion, 5 parts of propylene glycol methyl ether, 0.5 parts of bentonite, 0.5 parts of Tech-6208 dispersant, 0.5 parts of fumed silica, 70 parts of rare earth modified zinc powder, and 0.5 parts of silicone defoamer 1 part, 1 part of sulfur-containing high-efficiency corrosion inhibitor, 10 parts of water.

[0061] The steps of the preparation method are the same as in Example 1.

Embodiment 3

[0063] A water-based one-component organic zinc-rich coating, the components are as follows:

[0064] 20 parts of water-based one-component epoxy resin emulsion, 8 parts of propylene glycol methyl ether, 1.5 parts of bentonite, 0.8 parts of Tech-6208 dispersant, 1 part of fumed silica, 100 parts of rare earth modified zinc powder, and 0.1 parts of silicone defoamer parts, 0.5 parts of sulfur-containing high-efficiency corrosion inhibitor, and 10 parts of water.

[0065] The steps of the preparation method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com