A peek modified polyurethane anti-corrosion and anti-radiation water-based coating for steel structures

A water-based coating, polyurethane technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of high strict requirements of nuclear power plants, unsatisfactory radiation protection performance, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

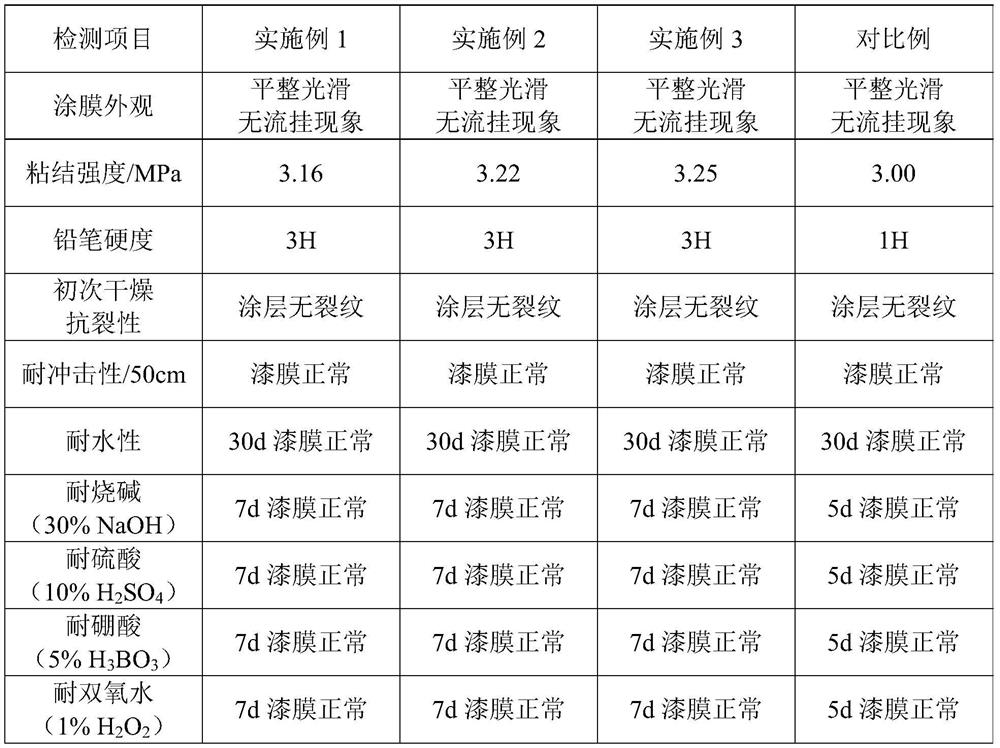

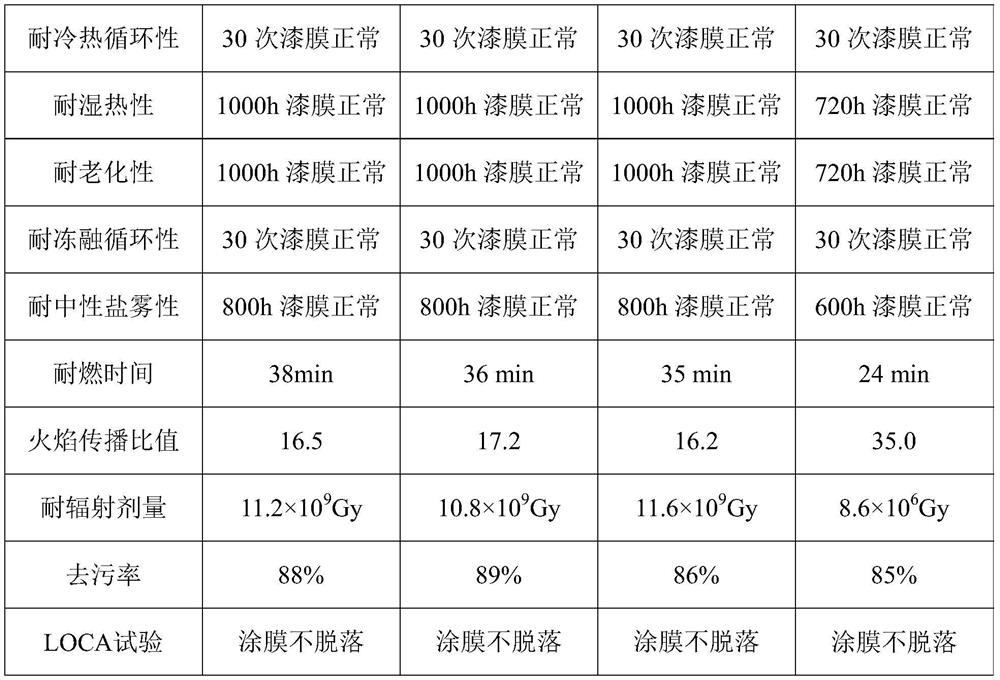

Embodiment 1

[0033] A PEEK-modified polyurethane anti-corrosion and anti-radiation water-based paint for steel structure, which consists of: 42.0 parts of PEEK modified polyurethane water-based resin A, 2.5 parts of dipropylene glycol butyl ether, 1.5 parts of dispersant, zinc phosphate 7.0 parts, potassium titanate whiskers 10.0 parts, nano-LaB 6 3.0 parts, 1.0 parts of silane coupling agent, 12.0 parts of mica powder, 8.0 parts of talc powder, 0.1 parts of leveling agent, 0.2 parts of defoaming agent, 2.0 parts of organic bentonite, 0.1 parts of pH regulator, 10.6 parts of deionized water;

[0034] Wherein, the PEEK-modified polyurethane water-based resin A is described in Example 4 of the invention patent "A Polyetheretherketone-modified polyurethane water-based resin and its preparation method".

Embodiment 2

[0036] A PEEK-modified polyurethane anti-corrosion and anti-radiation water-based paint for steel structures, which consists of: 40.0 parts of PEEK modified polyurethane water-based resin B, 2.0 parts of propylene glycol methyl ether, 1.6 parts of dispersant, 8.0 parts of zinc phosphate , 6.0 parts of zinc borate, 10.0 parts of potassium titanate whiskers, nano WO 3 2.0 parts, 1.0 parts of silane coupling agent, 10.0 parts of mica powder, 6.0 parts of talc powder, 0.1 parts of leveling agent, 0.2 parts of defoamer, 3.0 parts of organic bentonite, 0.1 part of pH regulator, 10.0 parts of deionized water;

[0037] Wherein, the PEEK-modified polyurethane water-based resin B is described in Example 5 of the invention patent "A Polyetheretherketone-modified polyurethane water-based resin and its preparation method".

Embodiment 3

[0039] A PEEK-modified polyurethane anti-corrosion and anti-radiation water-based paint for steel structures, which consists of: 50.0 parts of PEEK modified polyurethane water-based resin C, 3.0 parts of dipropylene glycol butyl ether, 8.0 parts of barium metaborate, zinc phosphate 5.0 parts, nano Fe 2 o 3 6.0 parts, 2.0 parts of nano BN, 7.5 parts of mica powder, 5.0 parts of kaolin, 0.1 parts of leveling agent, 1.5 parts of dispersing agent, 1.0 parts of silane coupling agent, 0.1 parts of defoaming agent, 1.5 parts of anti-settling agent, pH regulator 0.1 parts, 9.2 parts of deionized water;

[0040] Wherein, the PEEK-modified polyurethane water-based resin C is described in Example 6 of the invention patent "A Polyetheretherketone-modified polyurethane water-based resin and its preparation method".

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| decontamination rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com