Method for continuous production of 1,3-propanediol by microorganisms

A technology of propylene glycol and microorganisms, which is applied in the field of bioengineering, can solve the problems of low concentration of 1,3-propanediol products and cannot significantly improve production efficiency, and achieve the effect of realizing repeated utilization and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Strain cultivation: take 70mL of activated bacterial liquid, mix it with 630mL of seed medium in a 1L fermenter, and carry out micro-aerobic culture (without nitrogen gas); the culture conditions are: culture temperature is 37°C, stirring speed is 200rpm , the pH was controlled at 7.0, and the fermented seed liquid was obtained after culturing for 18 hours.

[0033] (2) Continuous fermentation: The volume of the fermenter is 15L, and the liquid volume is 7L.

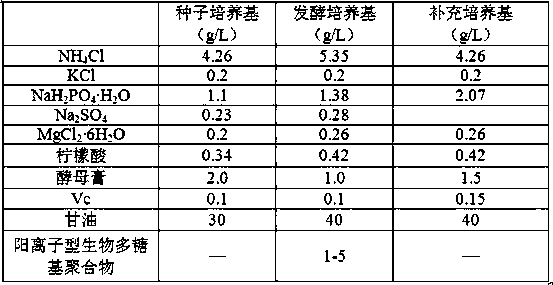

[0034] a. Take 700mL of fermented seed liquid and insert it into 6.3L of fermentation medium (medium-density chitosan with a molecular weight of 150,000 is added to the fermentation medium, and the addition amount is 1g / L).

[0035] b. Carry out anaerobic fermentation, and add glycerol during the fermentation process to maintain the glycerol concentration in the fermentation system at 40g / L; control the culture temperature during the fermentation process to be 37°C, pH to be 7.0, stirring speed to be 400rpm, a...

Embodiment 2

[0039] (1) Strain cultivation: Take 35mL of activated bacterial liquid, mix it with 665mL of seed medium in a 1L fermenter, and carry out micro-aerobic culture (without nitrogen inflow); the culture conditions are: culture temperature is 35°C, stirring speed is 100rpm , the pH was controlled at 7.0, and the fermented seed liquid was obtained after culturing for 24 hours.

[0040] (2) Continuous fermentation: The volume of the fermenter is 15L, and the liquid volume is 7L.

[0041] a. Take 350mL of fermented seed liquid and insert it into 6.65L of fermentation medium (medium-density chitosan with a molecular weight of 150,000 is added to the fermentation medium, and the amount added is 3.5g / L).

[0042] b. Carry out anaerobic fermentation, and add glycerin during the fermentation process to maintain the glycerin concentration in the fermentation system at 30g / L; control the culture temperature during the fermentation process to be 35°C, pH to be 7.0, stirring speed to be 400rpm...

Embodiment 3

[0046] (1) Strain cultivation: take 105mL of activated bacterial liquid, mix it with 595mL of seed medium in a 1L fermenter, and carry out micro-aerobic culture (without nitrogen inflow); the culture conditions are: culture temperature is 40°C, stirring speed is 300rpm , the pH was controlled at 7.0, and the fermented seed liquid was obtained after culturing for 18 hours.

[0047] (2) Continuous fermentation: The volume of the fermenter is 15L, and the liquid volume is 7L.

[0048] a. Take 700mL of fermented seed liquid and insert it into 6.3L of fermentation medium (medium-density chitosan with a molecular weight of 150,000 is added to the fermentation medium, and the addition amount is 3g / L).

[0049] b. Carry out anaerobic fermentation, and add glycerin during the fermentation process to maintain the glycerol concentration in the fermentation system at 35g / L; control the culture temperature during the fermentation process to be 40°C, pH to be 7.0, stirring speed to be 400rp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com