A heat treatment method for controlling heat treatment deformation of an inner ring gear

A heat treatment method and heat treatment deformation technology, which are applied in the field of heat treatment, can solve the problems affecting the heat treatment effect, the heating and cooling effect of the inner ring gear, etc., and achieve the effects of ensuring dimensional accuracy and roundness, high work efficiency, and high process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The characteristics and advantages of the present invention are described in detail below in conjunction with specific embodiments.

[0019] According to the purpose of the present invention, a heat treatment method for controlling heat treatment deformation of an inner ring gear of the present invention includes the following steps:

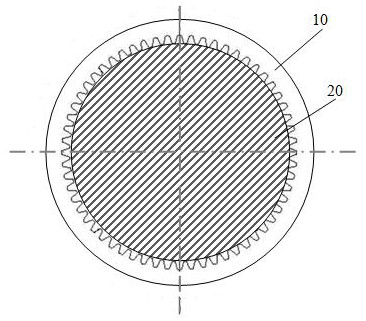

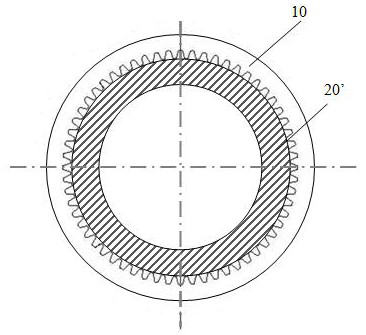

[0020] S1: Inspect the inner ring gear 10 to see if there are any defects such as cracks and damages on its surface; clean the inner ring gear with no defects on the surface of the inspection, and then dry it in an oven. The drying time is 20-25 minutes;

[0021] S2: The dried inner ring gear is sent to the heating chamber for C-N co-infiltration. First, the heating chamber is heated. At the beginning, all the heating tubes can be used to quickly heat up the furnace to shorten the process time; ammonia gas is introduced during the heating process, and the flow rate is controlled. 120-170L / h, stop heating when the temperature rises to 620-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com