Flux pellet produced by adding fluorine-contained magnetite concentrate and preparation method of flux pellet

A magnetite concentrate and flux-based technology, applied in the field of iron-making raw material pellets, can solve the problems of low SiO2 and other problems, and achieve the effects of improving metallurgical properties, suppressing reduction expansion rate, and rational allocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

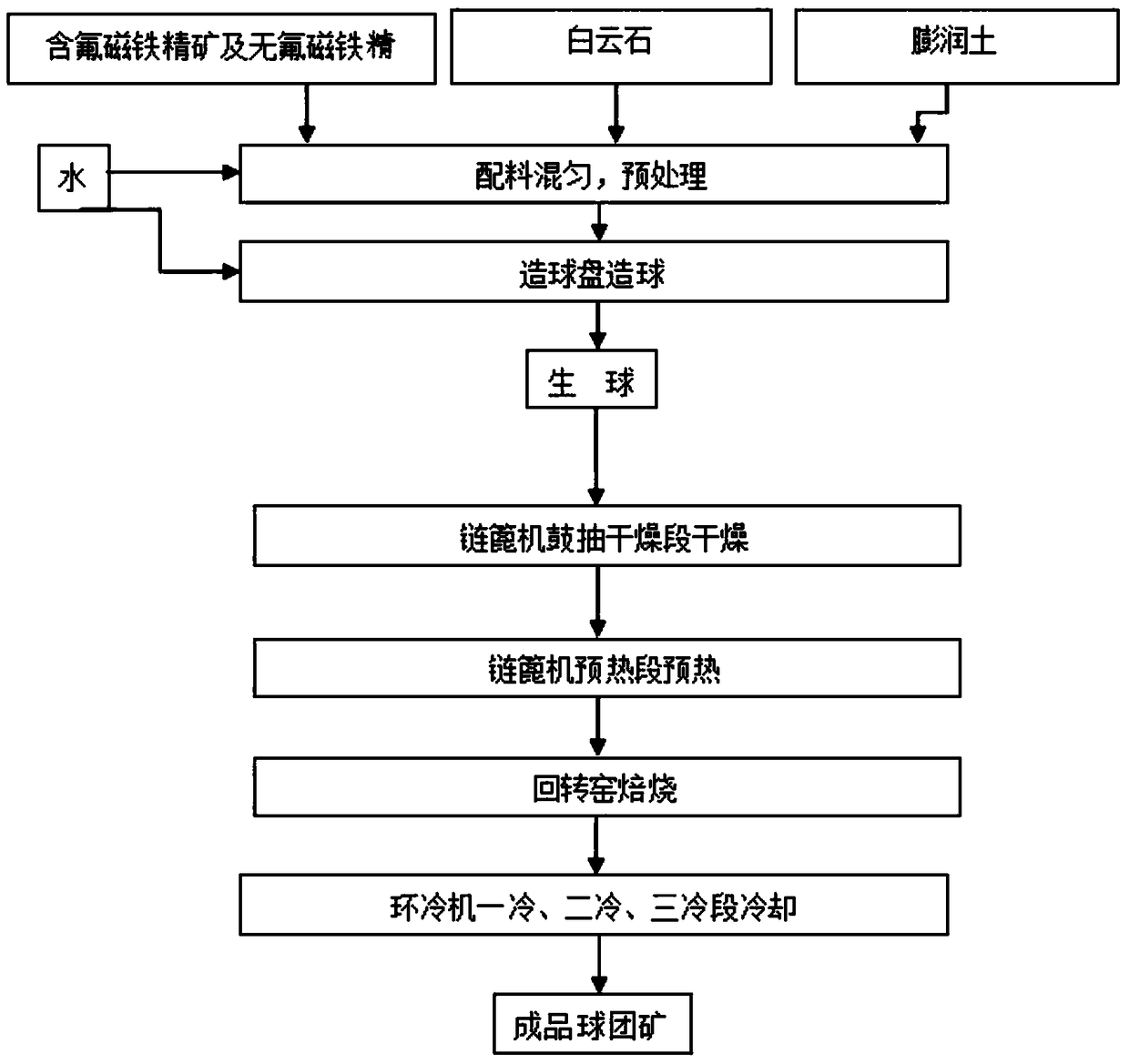

[0032] Such as figure 1 Shown, a kind of preparation method of adding the flux property pellet produced by adding fluorine-containing magnetite concentrate comprises the following steps:

[0033] S1. Pellet the mixture in a Φ6m pelletizing tray to obtain raw pellets, and then spread the raw pellets evenly on the grate through the raw pellet distributing device and screening device. The thickness of the raw pellets of the chain grate is 190mm-200mm. The speed of the grate machine is 1.95m / min~2.05m / min;

[0034] S2. Dry the raw balls through the blast drying section of the chain grate machine and the exhaust drying section. The conditions of the blast drying section: the temperature of the air box in the blast drying section is controlled at 230 ° C ~ 250 ° C, and the pressure of the air box in the blast drying section is controlled. At 0.10kpa ~ 0.15kpa, the temperature of the hood in the air blast drying section is controlled at 50°C ~ 60°C, and the time is 2.90min ~ 3.10min...

Embodiment

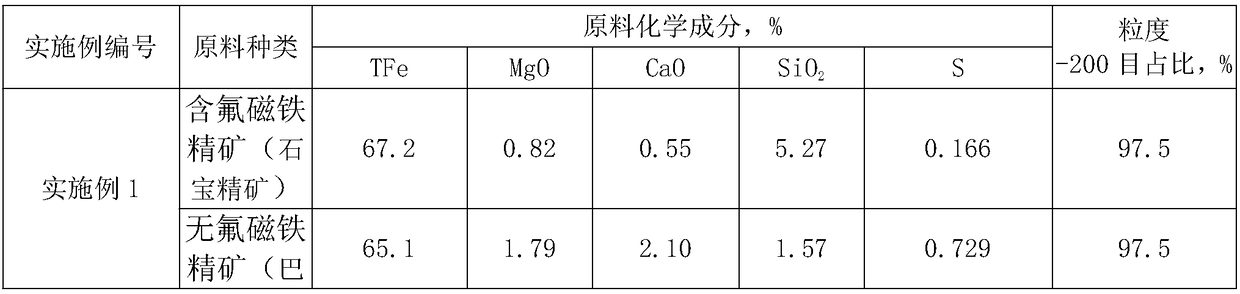

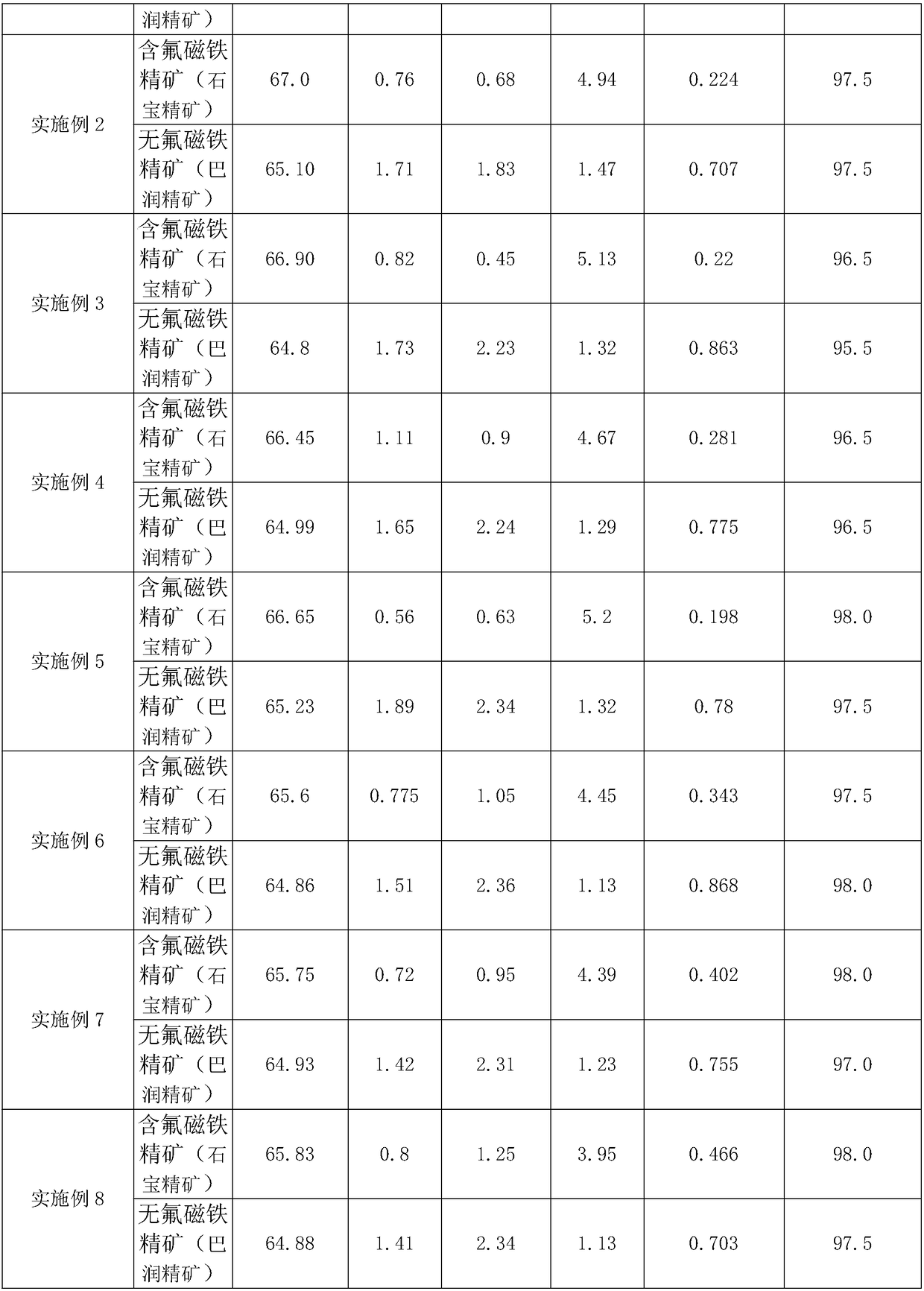

[0042] In each embodiment, the production of low-silicon, high-magnesium and fluorine-containing flux pellets by using the grate machine-rotary kiln-circular cooler process, the raw material composition, raw material configuration, process parameters, finished ball composition, and related properties of the finished ball are shown in Table 1. -7.

[0043] Each embodiment raw material chemical composition of table 1 and particle size statistics

[0044]

[0045]

[0046] It can be seen from Table 1 that:

[0047] The variety of iron materials used in each embodiment is relatively single, the particle size is fine, and the composition stability is good, which is conducive to improving the pelletizing process.

[0048] Raw material ratio statistics of each embodiment of table 2

[0049]

[0050] Table 3 statistics of green ball quality data in each embodiment

[0051]

[0052] It can be seen from Table 3:

[0053] (1) During the implementation of the project, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com