A kind of multifunctional coated nonwoven fabric and its preparation method

A non-woven fabric, multi-functional coating technology, applied in the direction of non-woven fabrics, textiles and paper making, etc., to achieve the effect of facilitating water expansion, preventing dust absorption, and preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

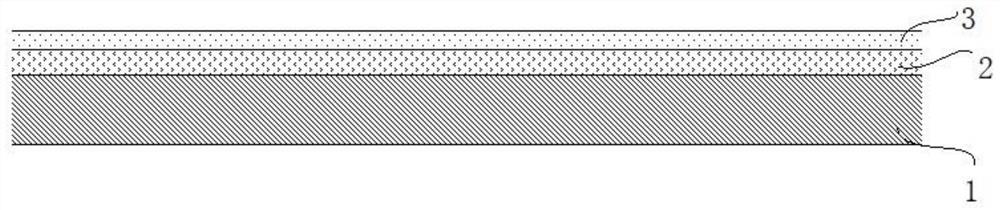

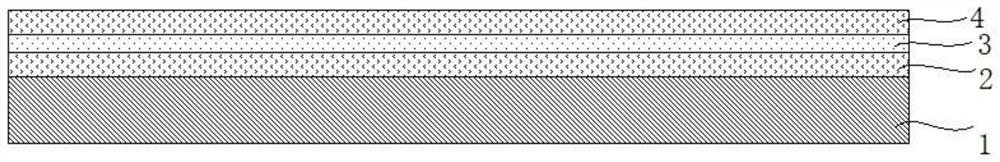

[0041] A kind of multifunctional coating nonwoven fabric, comprises superabsorbent fiber layer 1, low melting point fiber layer 2 and graphene coating 3 (see figure 1 ), the superabsorbent fiber layer is arranged on the bottom of the low-melt fiber layer, the graphene coating is coated on one side of the low-melt fiber layer, and part of the fibers in the low-melt fiber layer extend into the superabsorbent fiber layer , some of the fibers in the superabsorbent fiber layer extend into the low-melting fiber layer.

[0042] The low-melt fiber in the low-melt fiber layer is the first low-melt fiber. The first low-melting fiber is a composite fiber whose skin layer is polyethylene and core layer is polypropylene.

[0043] The superabsorbent fiber layer includes superabsorbent fiber, chemical fiber that acts as a skeleton, and second low-melting fiber that acts as a bond and fixer. The melting point of the chemical fiber serving as a skeleton is higher than the melting point of th...

Embodiment 2

[0054] A multi-functional coated non-woven fabric, comprising a superabsorbent fiber layer 1, a low melting point fiber layer 2 and a graphene coating 3, the superabsorbing fiber layer is arranged on the lower part of the low melting point fiber layer, and the graphene coating Coated on one side of the low-melting fiber layer, some fibers in the low-melting fiber layer extend into the superabsorbent fiber layer, and some fibers in the superabsorbent fiber layer extend into the low-melting fiber layer.

[0055] The low-melt fiber in the low-melt fiber layer is the first low-melt fiber. The first low-melting fiber is polyethylene fiber.

[0056] The superabsorbent fiber layer includes superabsorbent fiber, chemical fiber that acts as a skeleton, and second low-melting fiber that acts as a bond and fixer. The melting point of the chemical fiber serving as a skeleton is higher than the melting point of the second low-melting fiber in the superabsorbent fiber layer. The chemical ...

Embodiment 3

[0068] A multi-functional coated non-woven fabric, comprising a superabsorbent fiber layer 1, a low melting point fiber layer 2 and a graphene coating 3, the superabsorbing fiber layer is arranged on the lower part of the low melting point fiber layer, and the graphene coating Coated on one side of the low-melting fiber layer, some fibers in the low-melting fiber layer extend into the superabsorbent fiber layer, and some fibers in the superabsorbent fiber layer extend into the low-melting fiber layer.

[0069] The low-melt fiber in the low-melt fiber layer is the first low-melt fiber. The first low-melting fiber is polyethylene fiber.

[0070] The superabsorbent fiber layer includes superabsorbent fiber, chemical fiber that acts as a skeleton, and second low-melting fiber that acts as a bond and fixer. The melting point of the chemical fiber serving as a skeleton is higher than the melting point of the second low-melting fiber in the superabsorbent fiber layer. The chemical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com