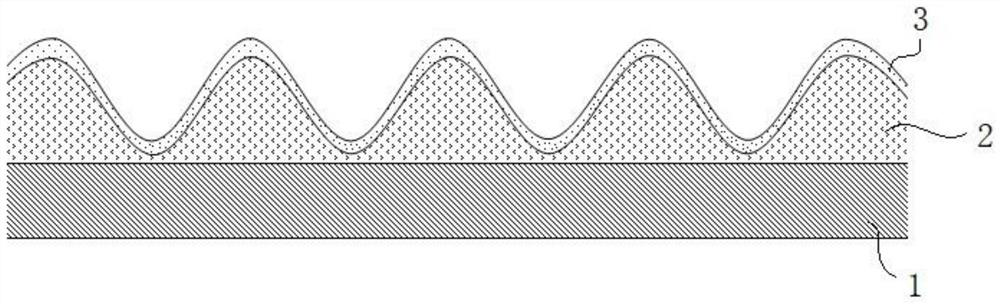

Multifunctional nonwoven fabric with polymer coating and production method thereof

A technology of non-woven fabrics and production methods, applied in the field of textiles, to achieve the effect of preventing dust absorption, preventing condensation, and widening the scope and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

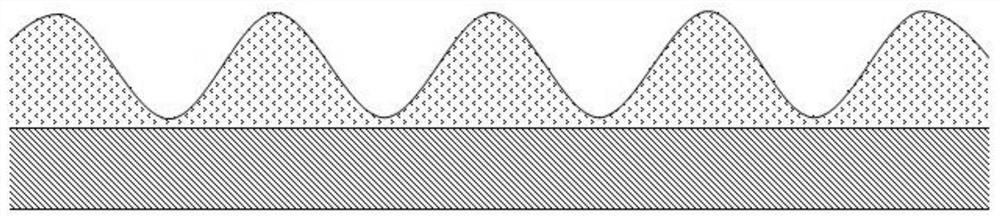

Method used

Image

Examples

Embodiment 1

[0047] A kind of production method of the multifunctional nonwoven fabric of polymer coating, comprises the steps:

[0048] (1) Opening and mixing: take superabsorbent fibers, chemical fibers acting as a skeleton (in this embodiment, PET fibers) and low-melting fibers according to the ratio of parts by weight of 15:30:25, and carry out opening and mixing; , take a certain weight of ordinary fiber and open it, the melting point of the ordinary fiber is at least 20°C higher than the melting point of the low melting point fiber; the linear density of the ordinary fiber is less than the linear density of the low melting point fiber, the ordinary fiber The linear density is 1.3dtex, and the linear density of the low-melting fiber is 1.8dtex; the low-melting fiber here is a low-melting polyester (LPET) fiber; the linear density of the PET fiber is 3dtex, and the fiber length is 38mm;

[0049] (2) Carding: Carding the superabsorbent fibers after opening and mixing, chemical fibers ac...

Embodiment 2

[0056] A kind of production method of the multifunctional nonwoven fabric of polymer coating, comprises the steps:

[0057](1) Opening and mixing: take superabsorbent fibers, chemical fibers that play a skeleton role (selected as PBT fibers in this embodiment) and low-melting point fibers according to the weight and number ratio of 40:30:25, and carry out opening and mixing; , take a certain weight of ordinary fiber and open it, the melting point of the ordinary fiber is at least 20°C higher than the melting point of the low melting point fiber; the linear density of the ordinary fiber is less than the linear density of the low melting point fiber, the ordinary fiber Linear density is 1.7dtex, and the linear density of described low melting point fiber is 3.0dtex; The low melting point fiber here is polyethylene fiber; The linear density of PBT fiber is 6dtex, and fiber length is 50mm;

[0058] (2) Carding: Carding the superabsorbent fibers after opening and mixing, chemical f...

Embodiment 3

[0065] A kind of production method of the multifunctional nonwoven fabric of polymer coating, comprises the steps:

[0066] (1) Opening and mixing: take the superabsorbent fiber, the chemical fiber that plays a skeleton role (the present embodiment is selected as PTT fiber) and the low-melting point fiber according to the weight and number ratio of 20:29:10, and carry out opening and mixing; , take a certain weight of ordinary fiber and open it, the melting point of the ordinary fiber is at least 20°C higher than the melting point of the low melting point fiber; the linear density of the ordinary fiber is less than the linear density of the low melting point fiber, the ordinary fiber The linear density is 1.5dtex, and the linear density of the low-melting fiber is 2.5dtex; the low-melting fiber here is a low-melting polyester (LPET) fiber; the linear density of the PTT fiber is 4.5dtex, and the fiber length is 45mm;

[0067] (2) Carding: Carding the superabsorbent fibers after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com