Pipe column recognition and collar positioning device and method for iron roughneck

A positioning device, the technology of the iron driller, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of low efficiency, inconvenient working height of the iron driller, damage to the pipe string, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings.

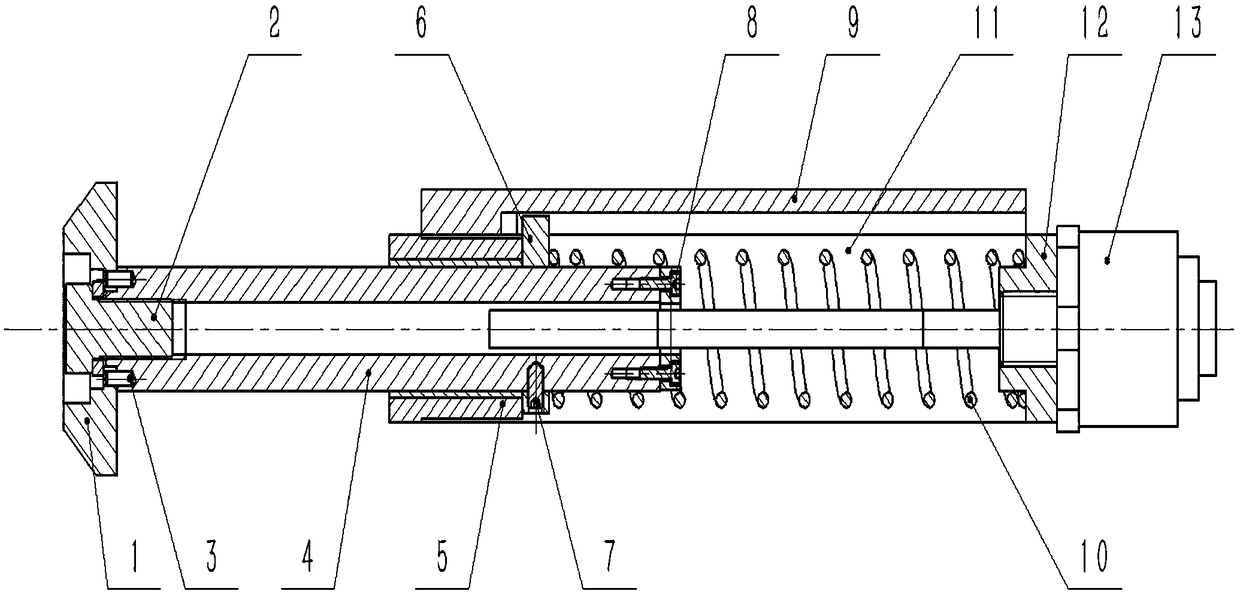

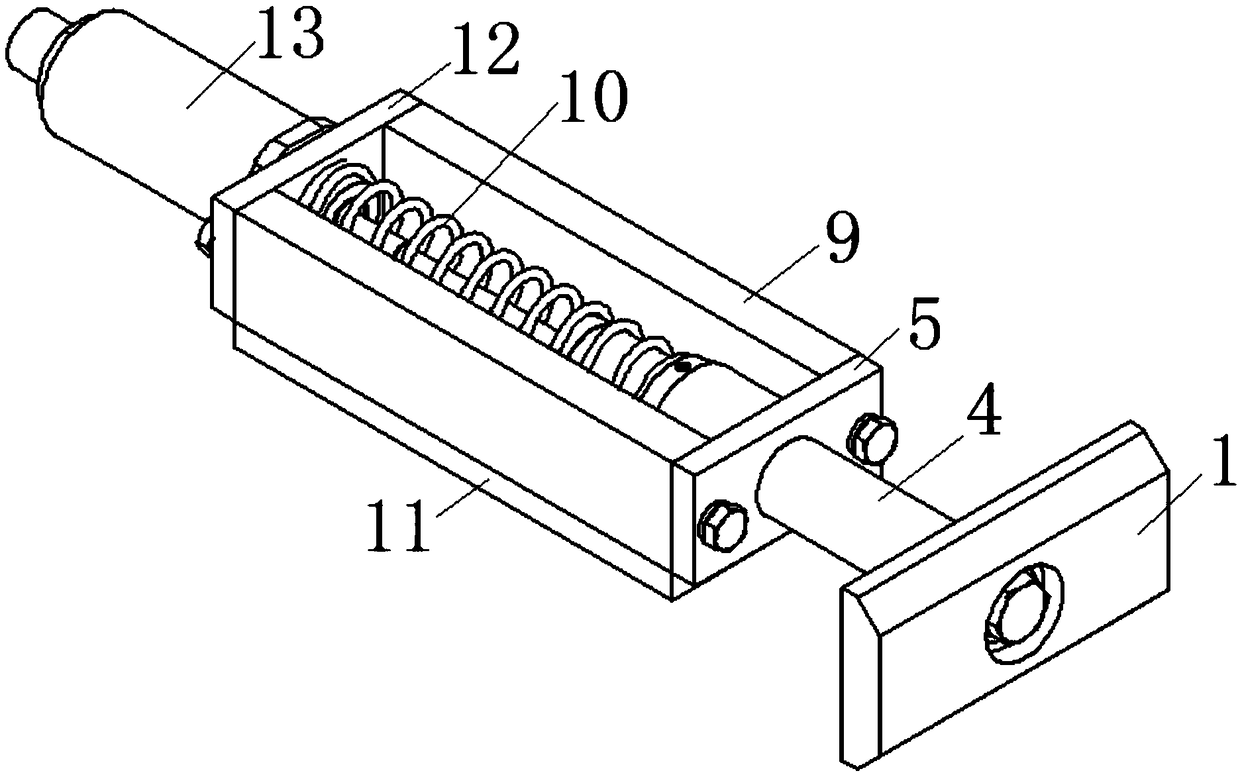

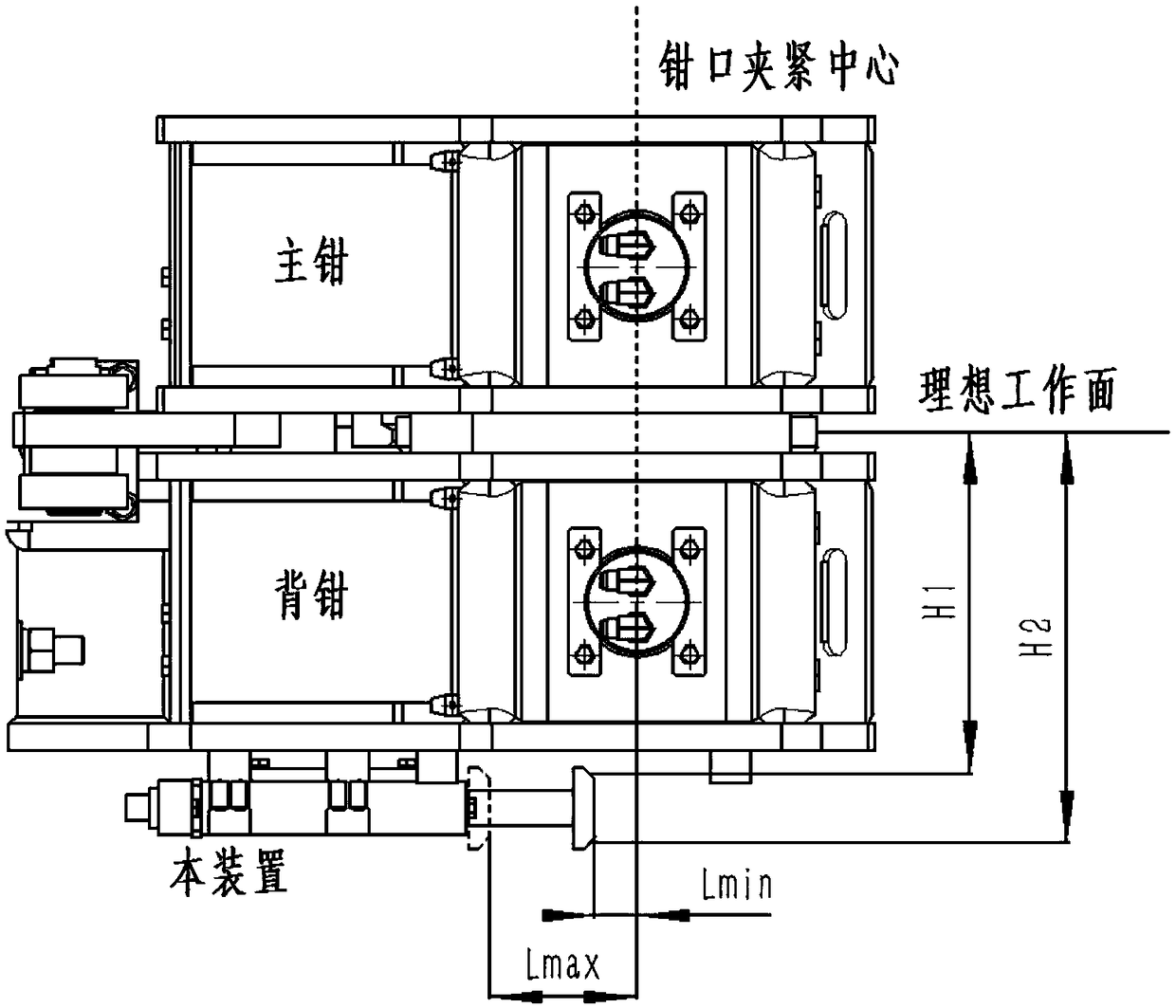

[0020] Such as Figure 1a , Figure 1b As shown, an iron driller pipe string identification and coupling end face positioning device includes a displacement sensing part, a mounting assembly and a sliding assembly, and a spring 10. The displacement sensing part consists of a displacement sensor 13 and a magnetic ring 8 Composition, the installation assembly is assembled by the front cover 5, two cover plates 11, two side plates 9 and the rear cover 12, the sliding assembly includes a sliding detection block 1, a sleeve 4, a front spring The retaining ring 6 is characterized in that the sliding detection block 1 is installed on the front end of the casing 4 through the fastening bolt 2, and two cylindrical pins are used for reinforcement between the sliding detection block 1 and the casing 4, and the cylindrical pin 3 is used to limit sliding Detect the rotational move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com