Automatic liquid nitrogen filling system of FTIR on-line monitoring instrument and control method of automatic liquid nitrogen filling system

A monitoring instrument and automatic filling technology, applied in the container discharge method, container filling method, instrument and other directions, can solve the problems of wasting labor, affecting the detection accuracy of the instrument, and difficult to ensure the continuous supply of liquid nitrogen, etc. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] As one of the embodiments of the present invention, the pressure relief valve 22 is an electromagnetic pressure relief valve 22, the start and stop of the electric heating device 24 and the pressure relief valve 22 are all controlled by an automatic controller, and the automatic controller includes a timer, The automatic controller automatically controls the start and stop states of the electric heating device 24 and the pressure relief valve 22 according to the set time period. The specific control method of this embodiment is: open and close the electric heating device 24 and the pressure relief valve 22 according to the set time cycle cycle, and when the electric heating device 24 is turned on, the pressure relief valve 22 is closed synchronously, and when the electric heating device 24 is turned off The pressure relief valve 22 is opened synchronously, and the electric heating device 24 is opened once every 8-12 hours, and each time it is opened for 3-10 minutes.

...

Embodiment 2

[0042] As another embodiment of the present invention, the Dewar flask of the FTIR on-line monitoring instrument is also provided with a temperature sensor, and the signal output end of the temperature sensor is electrically connected with an automatic controller, and the automatic controller collects The signal controls the start and stop of the pressure relief valve 22 and the electric heating device 24 . The specific control method of this embodiment is: control the start and stop of the electric heating device 24 and the pressure relief valve 22 according to the collected signal of the temperature sensor installed in the Dewar vessel, specifically: when the temperature is higher than -180°C, turn on the electric heating device 24 and close the pressure relief valve 22, when the temperature is kept at <-193°C for 80 seconds, it is considered that the addition of liquid nitrogen is completed, at this time the electric heating device 24 is closed and the pressure relief valve ...

Embodiment 3

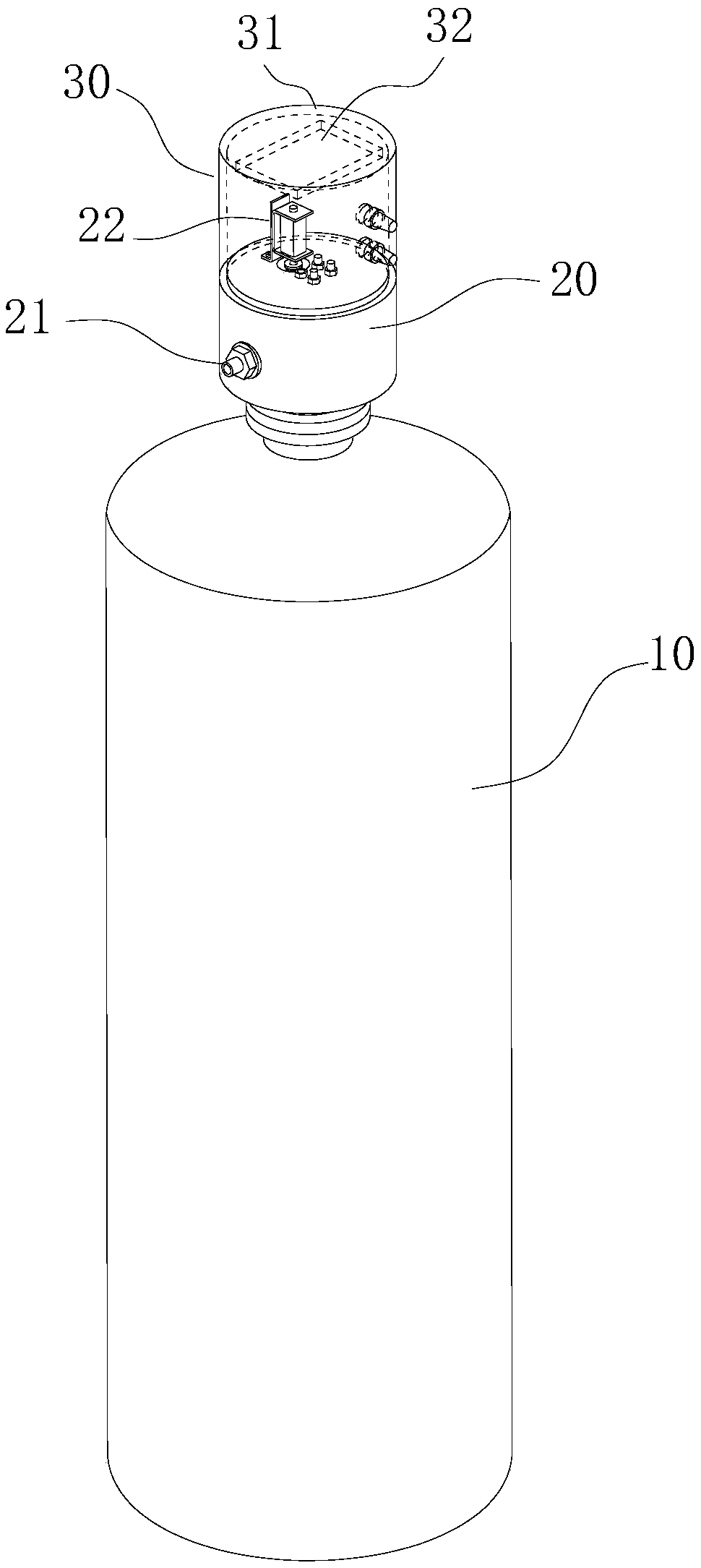

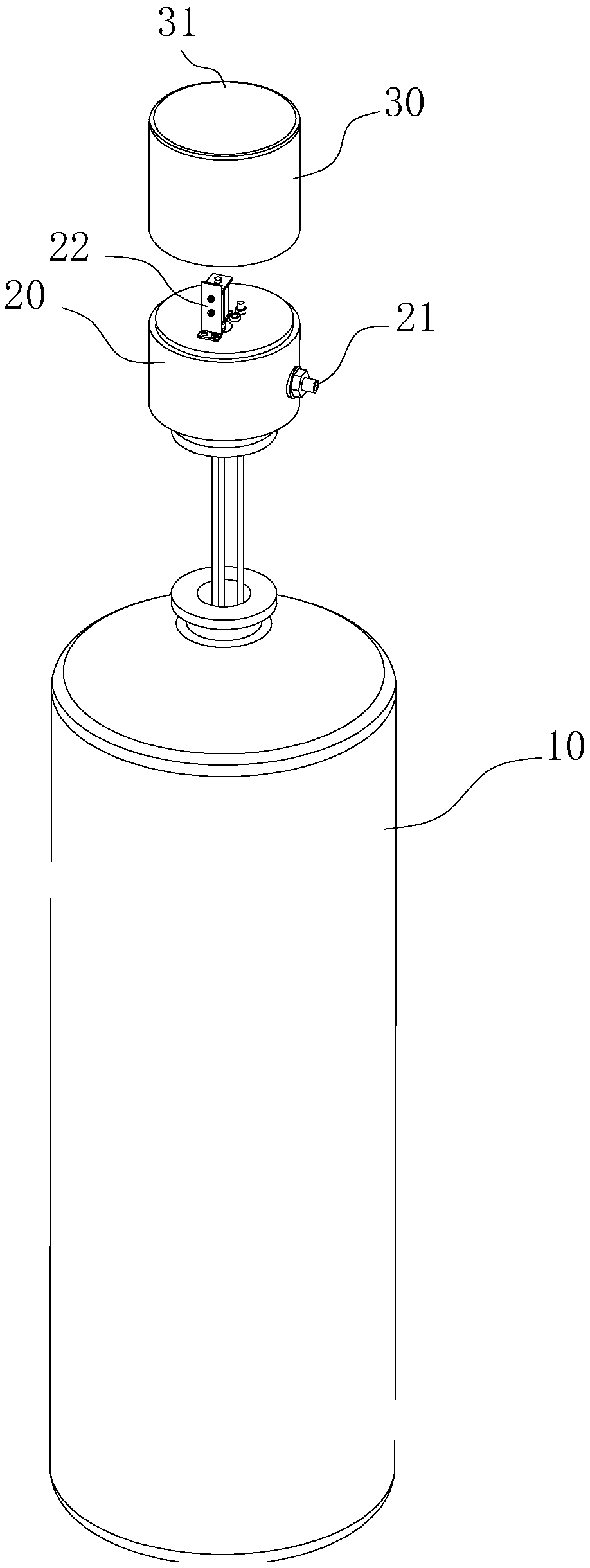

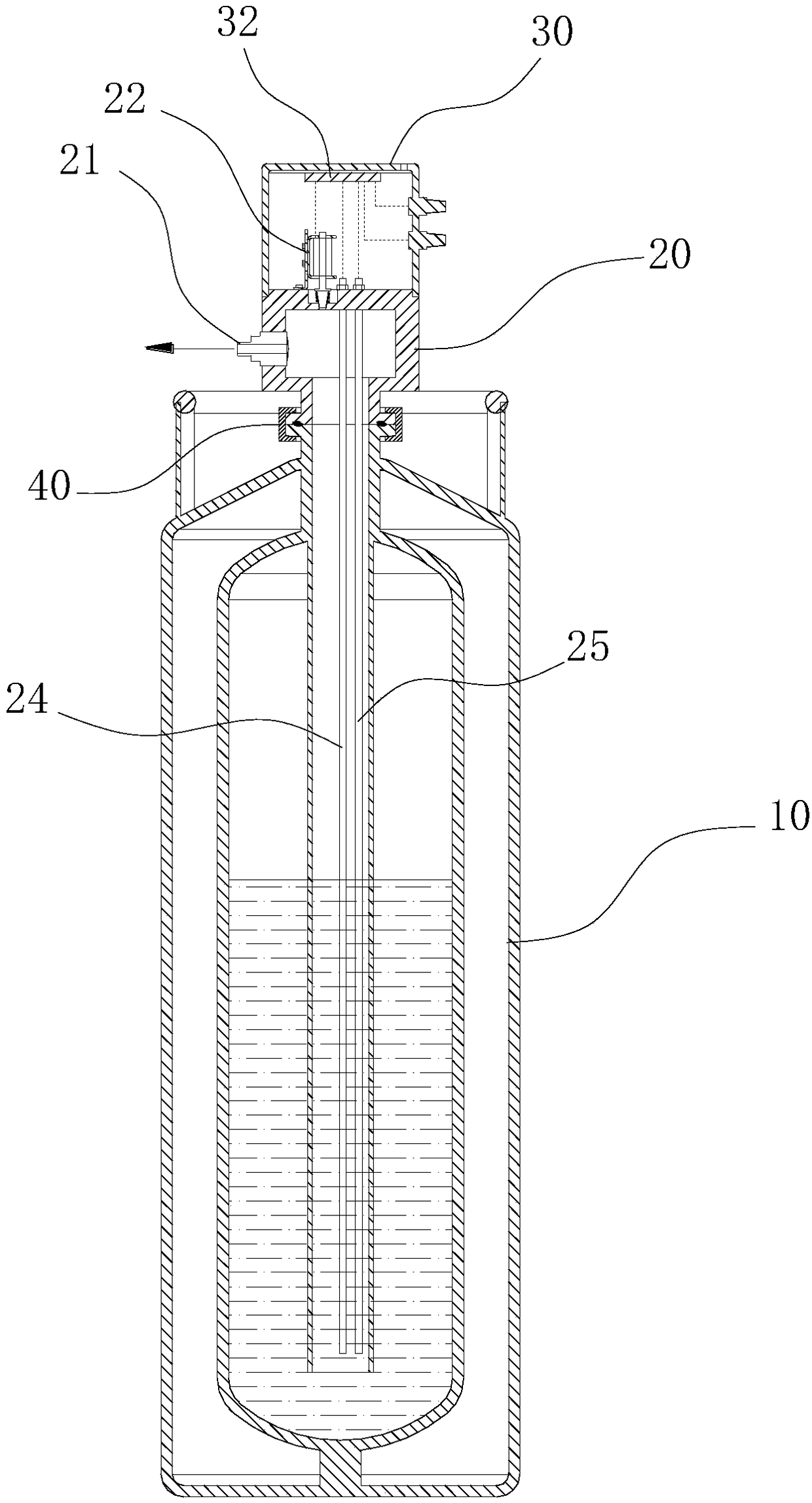

[0044] Such as Figure 4 , 5 As shown, a liquid nitrogen filling pump head includes a pump head base 20 provided at the mouth of the liquid nitrogen storage tank 10, an exhaust passage is opened in the pump head base 20, and the filling pipe 21 In series with the exhaust passage, the lead wires of the pressure relief valve 22 and the electric heating device 24 are installed on the pump head base 20, and a pressure sensor 23 and a safety valve are installed on the pump head base 20, and the safety pressure of the safety valve is set It is 20Kpa. The present invention integrates the design of the liquid nitrogen filling system, and all components are integrated on the pump head base 20, which greatly facilitates the disassembly and installation between the filling system and the liquid nitrogen storage tank 10, and facilitates quick replacement of liquid nitrogen storage tank10.

[0045] Specifically, the pressure relief valve 22 includes a conical spool 221, and the pump hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com