Method for Measuring Air Bubble Filtration Characteristics of Separation Mesh

A measurement method and bubble technology, which can be used in measurement devices, analytical materials, individual particle analysis, etc., can solve problems such as increasing the complexity of research on bubble motion characteristics, and achieve the effect of wide application conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

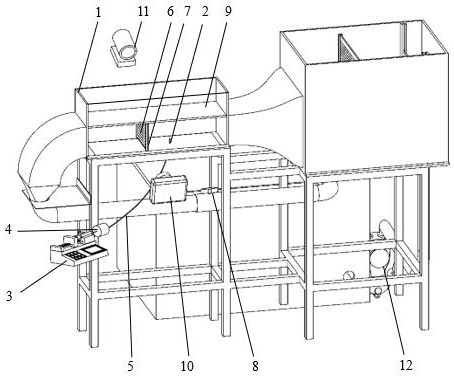

[0025] The present invention will be further described below in conjunction with accompanying drawing and example.

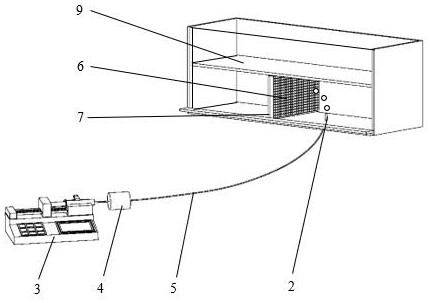

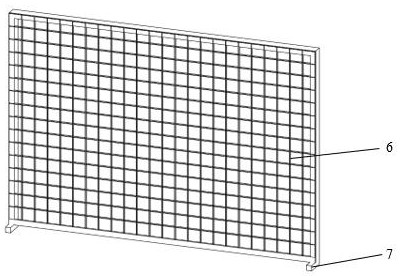

[0026]As shown in the figure, the overall embodiment of the present invention includes a separation screen 6 capable of separating gas and liquid in a water tank 1 , a bubble generating unit, a halogen lamp 10 and a high-speed camera 11 . The separation screen 6 is installed at a certain distance from the nozzle 2, and the distance between the separation screen 6 and the nozzle 2 can be changed according to different requirements. Shortening the distance from the nozzle 6 can study the separation and filtration characteristics of the bubbles near the wall surface, and increase When the distance between the two is large, it is possible to study the impact on the rising speed of the bubble on the screen when the bubble is subjected to a horizontal velocity. At the same time, the separation screen 6 of different sizes and shapes can be replaced, so as to better mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com