Laser light source of diffractive optical element coherent synthesis based on active optical feedback of ring cavity

A laser light source, coherent synthesis technology, applied in lasers, laser parts, optics, etc., can solve the problems of phase-locking effect being difficult to maintain stability, loss of seeds, laser frequency bandwidth, etc., to improve synthesis efficiency and total output power, solve Brightness enhancement, the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

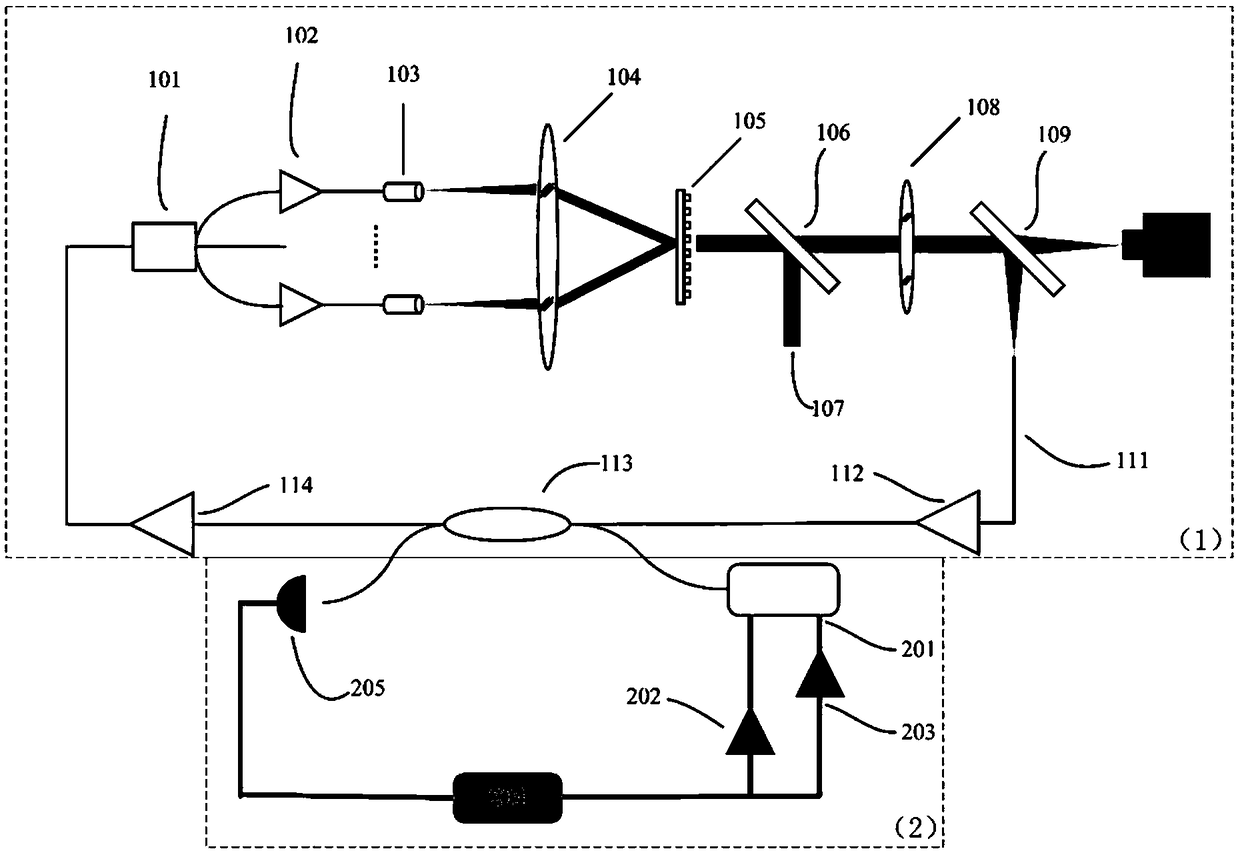

[0026] figure 1 It is a schematic diagram of the DOE coherent synthesis light source based on the ring cavity active optical feedback of the present invention. It can be seen from the figure that the present invention is based on the laser light source coherently combined by the diffractive optical element of the active optical feedback of the ring cavity, including the passive ring cavity 1 of the full optical feedback and the active photoelectric feedback loop 2,

[0027] The passive annular cavity 1 of the all-optical feedback includes sequentially connected 1×N fiber beam splitter 101, and the 1×N fiber beam splitter 101 divides the incident light into N paths, and passes through N-way fiber amplifiers 102, corresponding The output end cap array 103 and the first collimating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com