Orthopedic nursing crutch capable of relieving pain

A pain relief and orthopedic technology, applied in crutches, physical therapy, radiation therapy, etc., can solve problems affecting rehabilitation exercises, underarm skin wear, unbearable pain, etc., and achieve good applicability, pain relief, and increase static friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

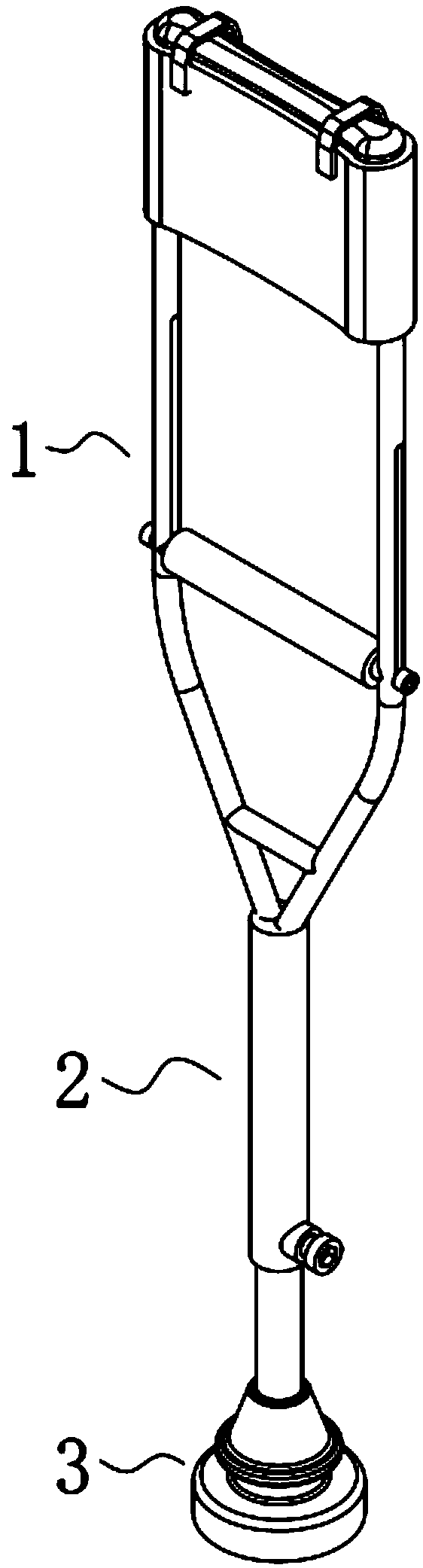

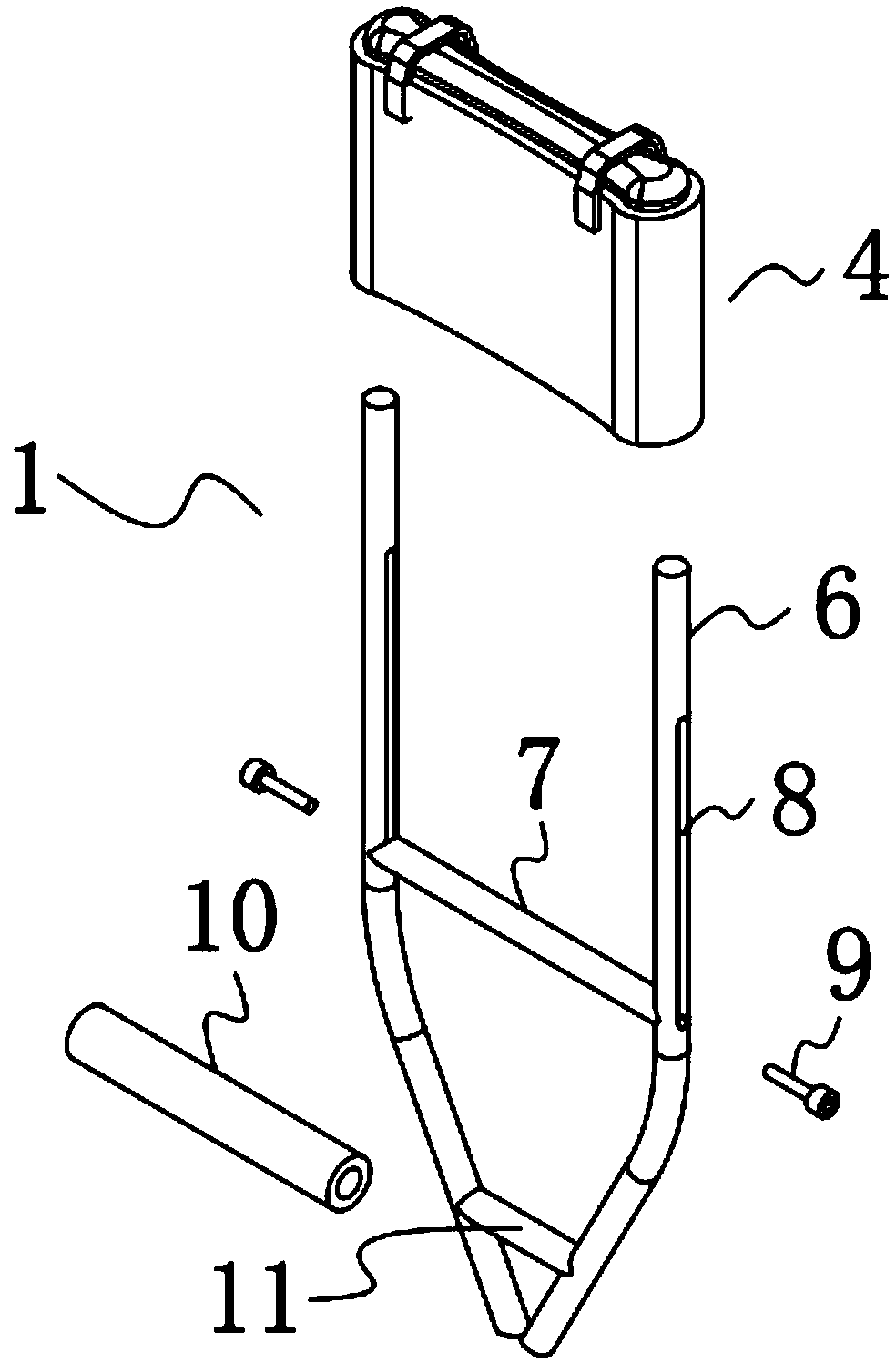

[0054] An orthopedic care crutch that relieves pain, such as figure 1 As shown, it includes a first support part 1 and a second support part 2, and the first support part 1 is fixedly installed on the upper part of the second support part 2;

[0055] Such as Figure 4 As shown, the second supporting part 2 includes an outer sleeve 19 and an inner insertion rod 20 movably inserted inside the bottom end of the outer sleeve 19, and the outside of the outer sleeve 19 is welded with a limit ring 21 near its bottom end, so The inside of the limit ring 21 is screwed with a fastening bolt 22 for locking the inner insertion rod 20;

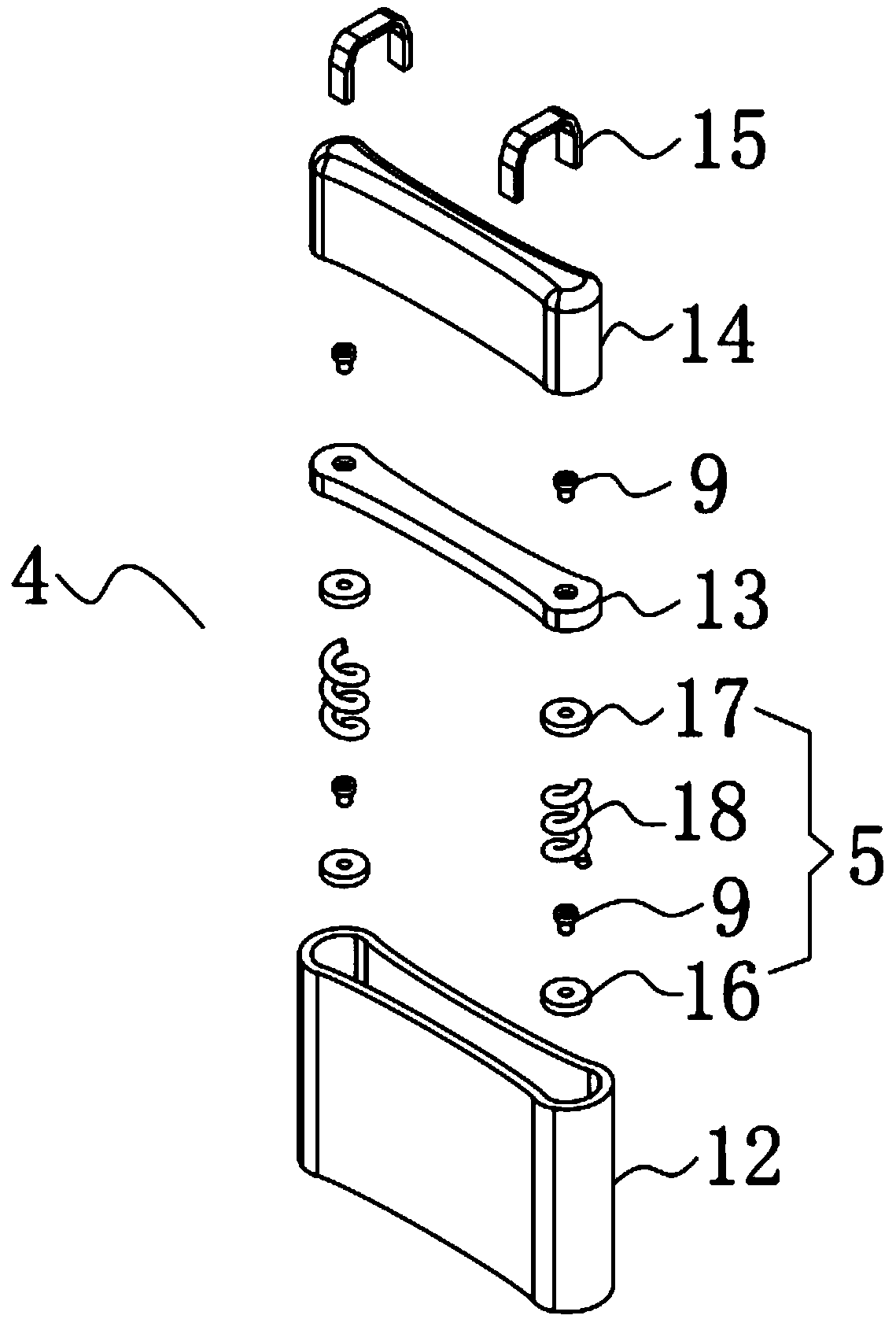

[0056] Such as figure 2 and 4 As shown, the first support part 1 includes two support curved rods 6 symmetrically welded on the upper end of the outer sleeve 19 and a pain relief unit 4 fixedly installed on the upper ends of the two support curved rods 6, two A through slot 8 is opened in the inside of the support bending rod 6 , and a cross bar 7 is ...

Embodiment 2

[0083] The difference from Example 1 is the preparation of the protective layer, and its specific preparation method is as follows: 60 parts of natural rubber, 40 parts of styrene-butadiene rubber, 40 parts of ethanol, 5 parts of silane coupling agent, 15 parts of calcium carbonate powder, epoxy 11 parts of resin particles, 3 parts of p-phenylenediamine, 4 parts of diethylthiourea, 6 parts of paraffin oil;

[0084] S1. Add the weighed natural rubber, styrene-butadiene rubber, ethanol, epoxy resin particles, calcium carbonate powder and silane coupling agent into the internal mixer for internal mixing. The temperature of the internal mixer is set to 130°C and the speed is set It is 700r / min, and the banburying time is 29min, and the banburying material is obtained;

[0085] S2. Add the banburying material prepared in step S1, p-phenylenediamine, diethylthiourea, and paraffin oil into the mixer for stirring and mixing. The temperature of the mixer is set to 230°C, the speed is s...

Embodiment 3

[0090] The difference from Example 1 is the preparation of the protective layer, and its specific preparation method is as follows:

[0091] Take the following raw materials and weigh them by weight: 70 parts of natural rubber, 50 parts of styrene-butadiene rubber, 50 parts of ethanol, 6 parts of silane coupling agent, 17 parts of calcium carbonate powder, 12 parts of epoxy resin particles, 4 parts of p-phenylenediamine , 5 parts of diethylthiourea, 7 parts of paraffin oil;

[0092] S1. Add the weighed natural rubber, styrene-butadiene rubber, ethanol, epoxy resin particles, calcium carbonate powder and silane coupling agent into the internal mixer for internal mixing. The temperature of the internal mixer is set to 140°C and the speed is set The banburying time is 800r / min, and the banburying time is 34min, and the banburying material is obtained;

[0093] S2. Add the banburying material prepared in step S1, p-phenylenediamine, diethylthiourea, and paraffin oil to the mixer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com