Cycloid gear machining fixture

A cycloidal gear and fixture technology, which is applied in the direction of manufacturing tools, metal processing equipment, gear tooth manufacturing devices, etc., can solve the problems of high production cost, difficult to achieve, high precision, etc., and achieve high clamping precision, low precision requirements, good The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

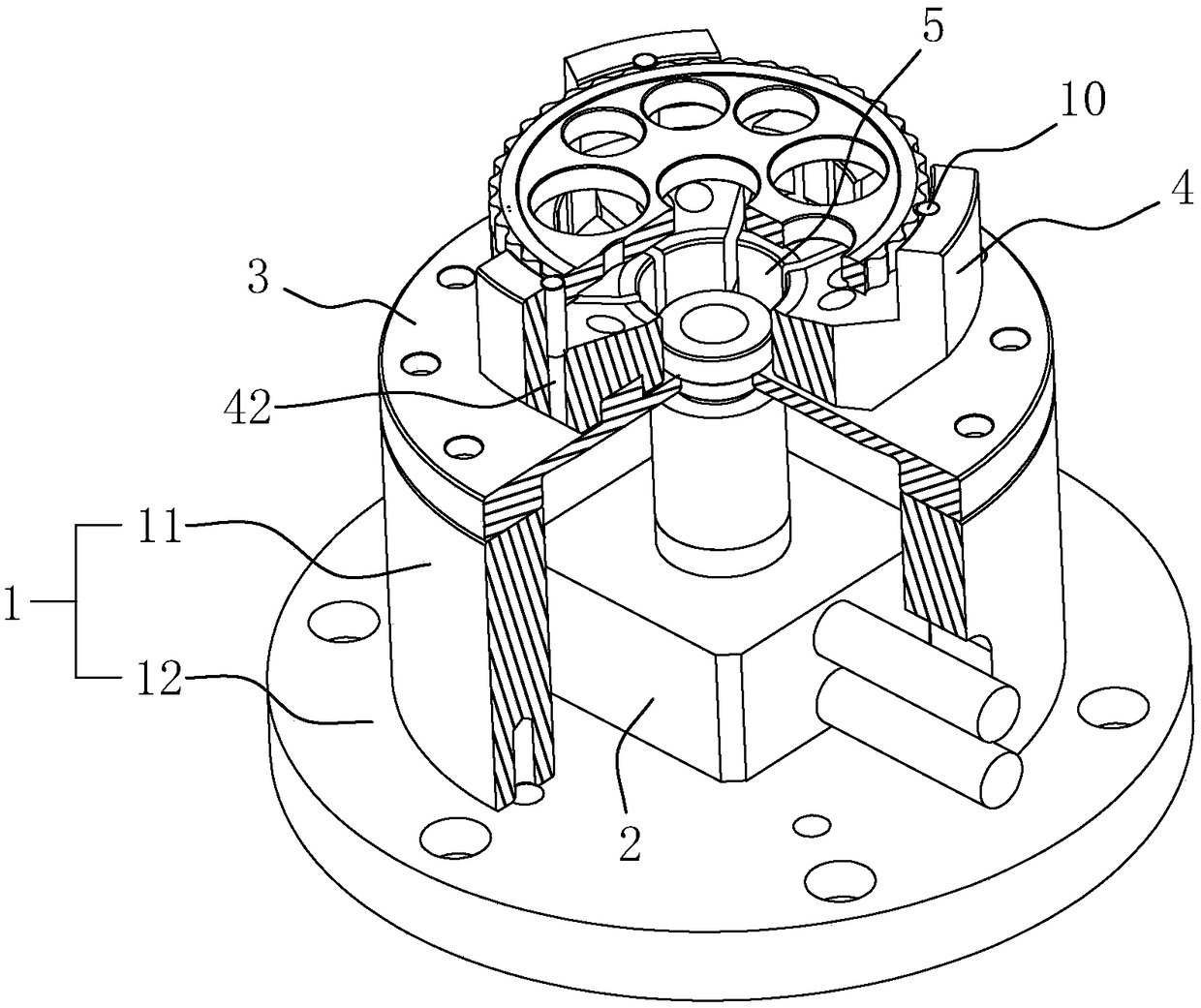

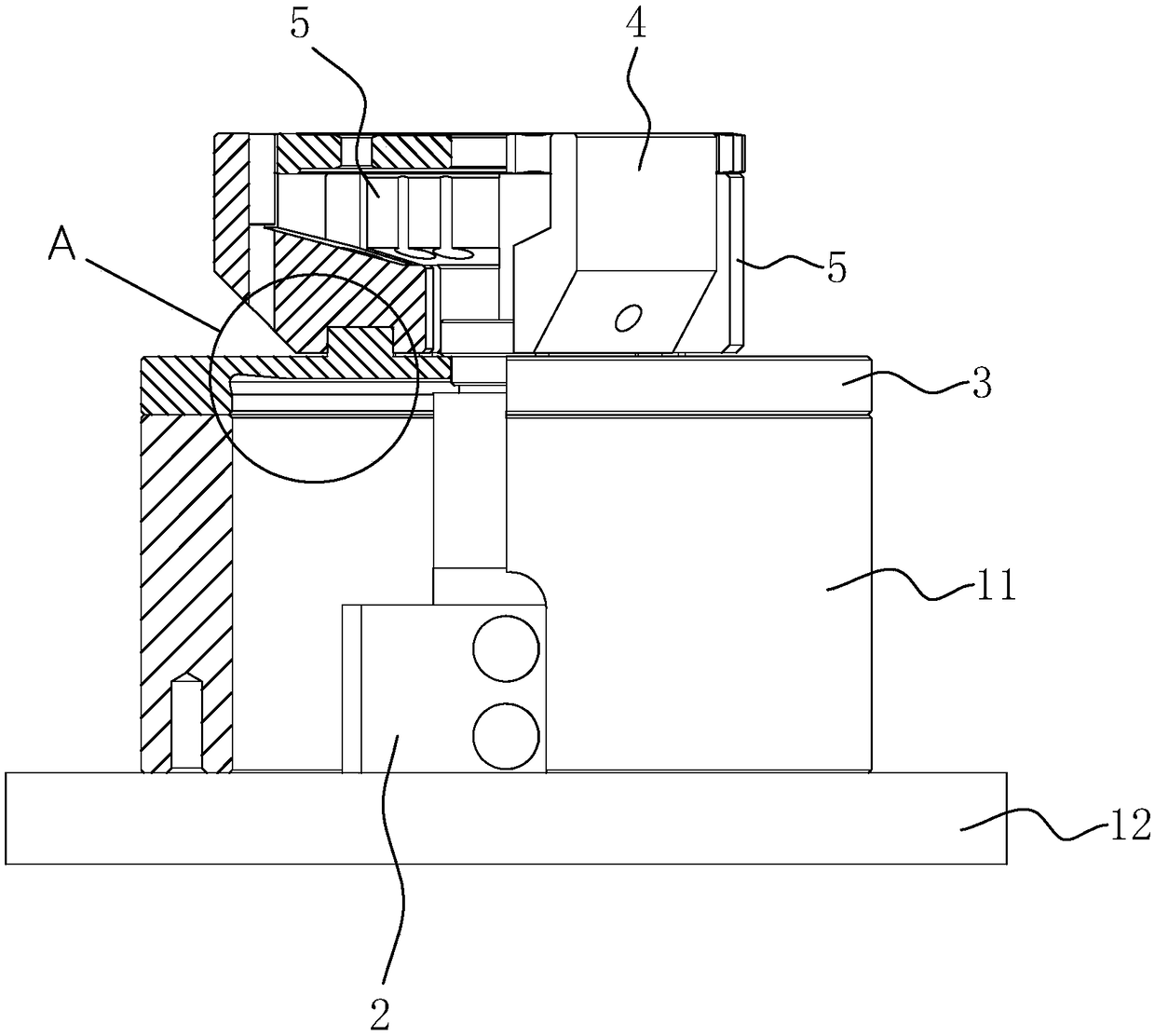

[0045] Embodiment 1: A kind of cycloidal gear machining fixture, such as figure 1 with figure 2 As shown, it includes a housing 1 , a supporting claw 5 , a clamping claw 4 , a diaphragm 3 and a driving element 2 .

[0046] The casing 1 includes a chassis 11 and a casing 12 , the casing 12 is in the shape of a cylinder with two ends open, and is mounted on the chassis 11 by bolts.

[0047] The drive element 2 can be a hydraulic cylinder or a pneumatic cylinder, preferably a hydraulic cylinder. The driving element 2 is fixedly installed on the chassis 11 and located in the casing 12 .

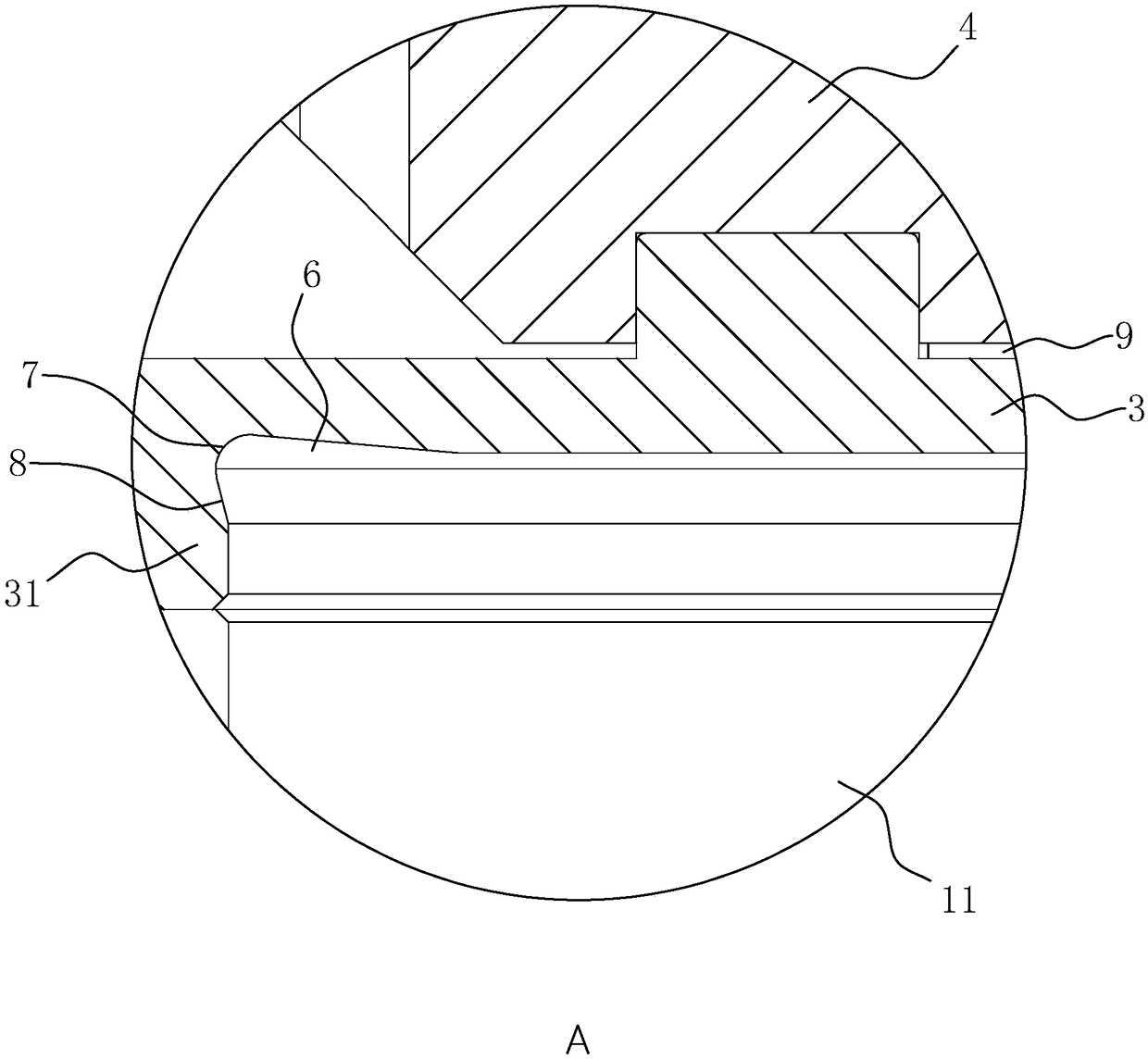

[0048] Diaphragm 3 is made of elastic steel, and a mounting part 31 is integrally provided around the edge of diaphragm 3 . The thickness of mounting part 31 is greater than that of diaphragm 3 , and the mounting part 31 is connected to housing 12 by bolts. A through hole is provided in the middle of the diaphragm 3 , and the piston rod of the driving element 2 is fixedly connected with the d...

Embodiment 2

[0056] Embodiment 2: as Figure 7 As shown, the difference from Embodiment 1 is that the bottom end faces of the claws 5 and 4 are placed against the end face of the diaphragm 3, and the maximum distance between the bottom end face of the jaw 4 and the center of the diaphragm 3 is less than the guide The minimum distance between the deformation part 6 and the center of the diaphragm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com