A processing technology for the upper plate of an H-shaped long beam

A processing technology and long beam technology, which is applied in the field of processing technology for H-shaped long beams, can solve the problems of high maintenance cost and poor adjustability, and achieve the effects of low maintenance cost, easy maintenance and strong adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

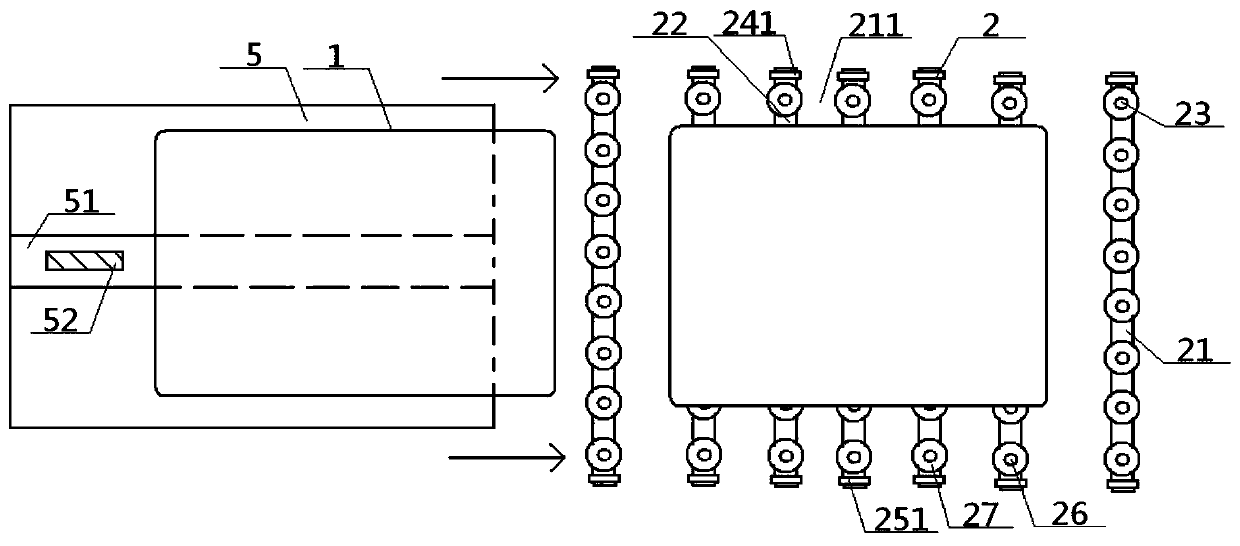

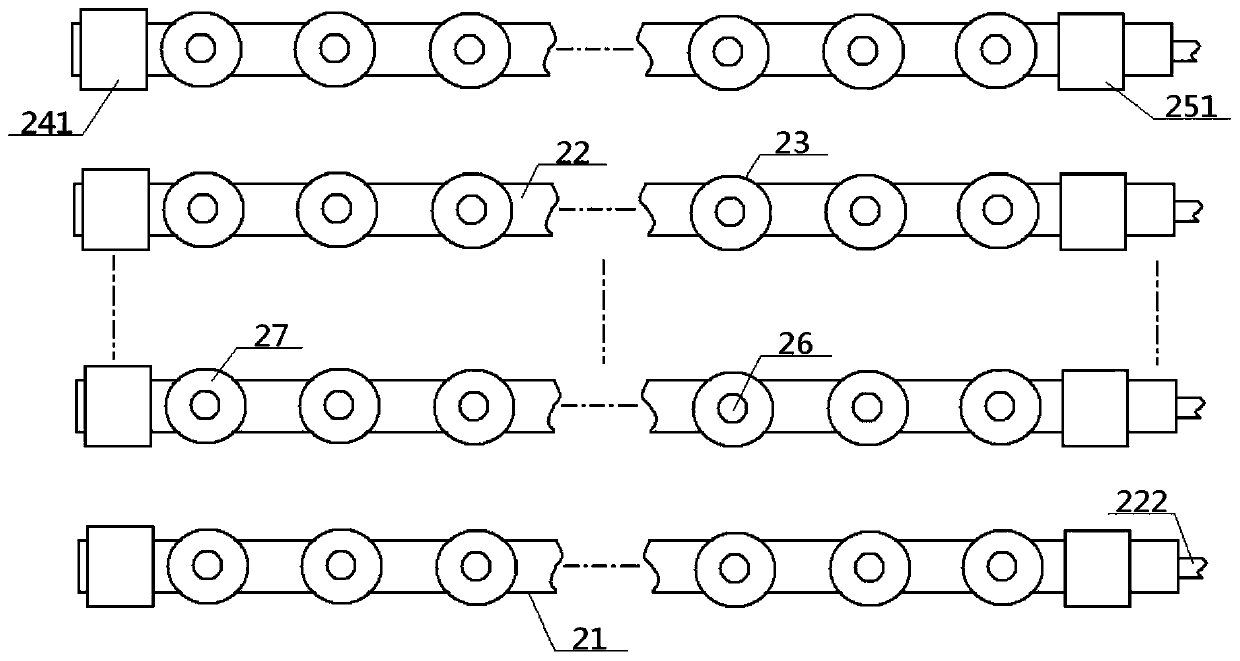

[0048] see Figure 1 to Figure 5 , a processing technology for plates used on H-shaped long beams, the processing technology includes the following steps: first transport the metal plate 1 to be processed to the plate feeding unit 5, and then drive the plate feeding pusher 52 along the plate feeding empty groove 51 Make a horizontal movement to push the metal sheet 1 to be processed onto the cutting unit 2, and then perform adjustment operations on each of the long support seats 21 in the cutting unit 2 to change the distribution of the long support seats 21 below the metal sheet 1 Density and the distance between the top of each strip support seat 21 and the bottom surface of the metal plate 1, the adjustment operation includes the horizontal movement and vertical movement of the strip support seat 21, after the adjustment operation is completed, the cutting unit 2 suspended above the cutting unit 2 The cutting machine performs a cutting operation on the sheet metal 1 .

[0...

Embodiment 2

[0051] Basic content is the same as embodiment 1, the difference is:

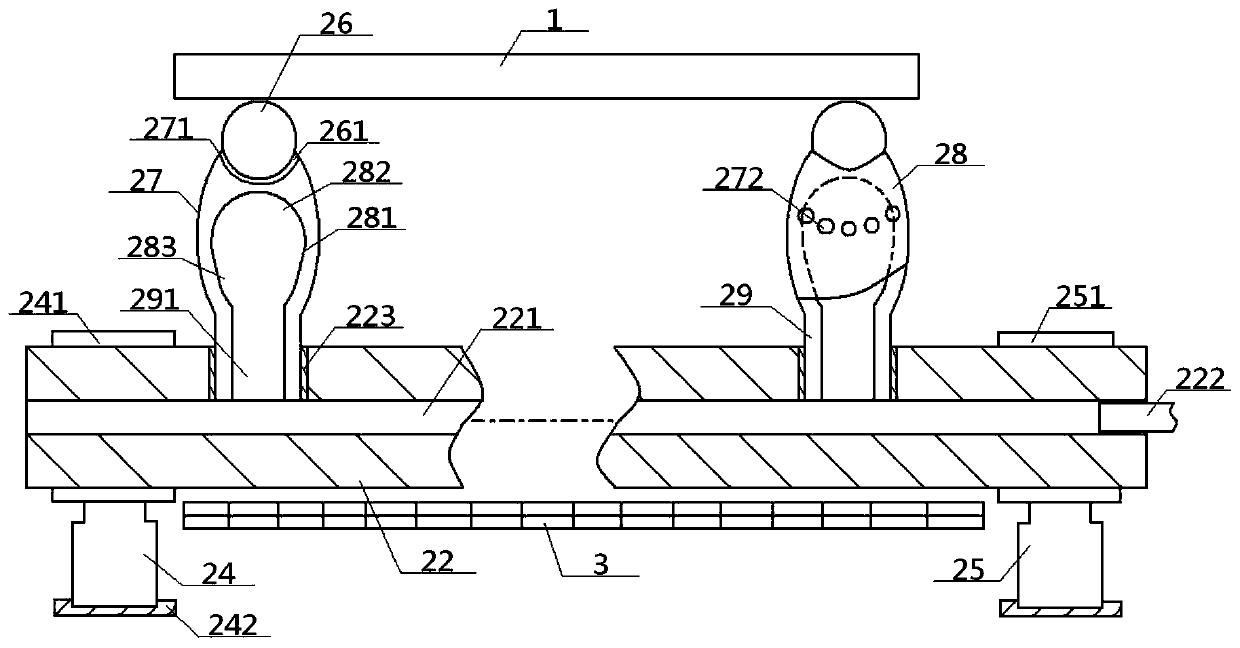

[0052] The elongated base 22 is a hollow structure, and the inside of the elongated base 22 is provided with a coaxial elongated cavity 221, one end of the elongated cavity 221 is flush with the end face of the elongated base 22, and the elongated cavity The other end of 221 is connected with the intake pipe head 222; the plastic ball seat 27 includes a spherical portion 28 and a fixed portion 29, the side of the spherical portion 28 is a spherical structure, and the side of the spherical portion 28 is provided with a plurality of Air vent 272, the top of spherical portion 28 is connected with the bottom of metal ball 26, the bottom of spherical portion 28 is connected with the top of fixed portion 29, and the bottom of fixed portion 29 passes through the top surface of elongated substrate 22 In contact with the strip cavity 221, the inside of the spherical portion 28 is provided with a spherical cavity 281...

Embodiment 3

[0054] Basic content is the same as embodiment 2, the difference is:

[0055] Described spherical cavity 281 comprises hemispherical body cavity 282 and conical frustum cavity 283, and the bottom end of described hemispherical body cavity 282 communicates with the top of fixed cavity 291 after passing through conical frustum cavity 283, and the top of conical frustum cavity 283 is wider than its bottom. end, and the vent hole 272 is arranged along the intersection line of the hemispherical cavity 282 and the conical cavity 283 . Preferably, the side circumference of the spherical portion 28 is an ellipsoid structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com