A kind of coal bunker construction technology

A construction technology and coal bunker technology, which is applied to shaft equipment, shaft lining, ground mining, etc., can solve the problems of large disturbance of surrounding rock, high labor intensity and low safety factor in blasting operations, reducing labor intensity and improving construction. Efficiency, easy assembly and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

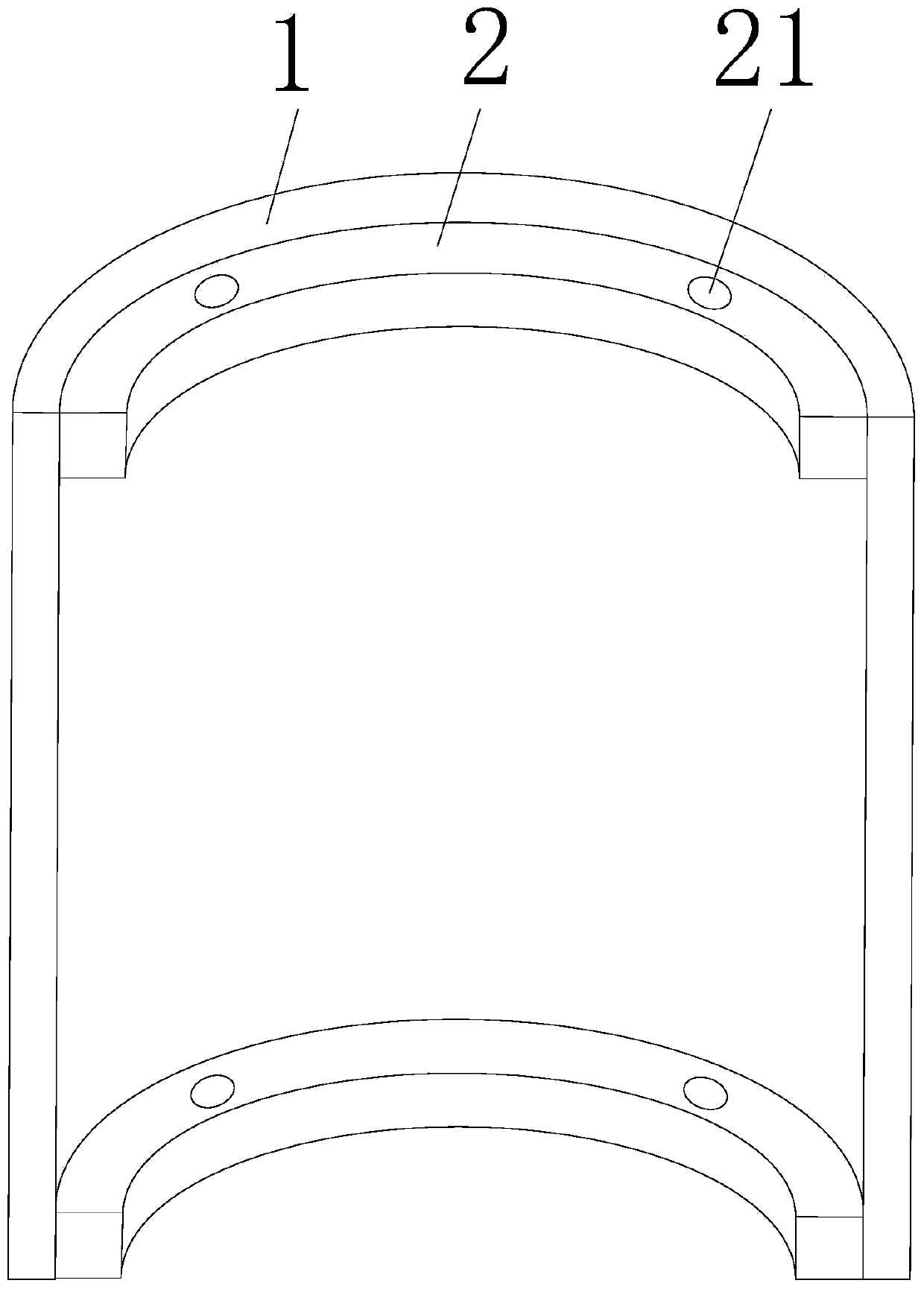

[0028] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

[0029] In this application, unless otherwise clearly stipulated and limited, the terms "connected", "connected", "fixed" and other terms should be understood in a broad sense, for example, it can be a fixed connection, a detachable connection, or an integrated ; It can be a mechanical connection, an electrical connection, or a communication; it can be a direct connection, or an indirect connection through an intermediary, and it can be an internal connection between two components or an interaction relationship between two components. Those of ordinary skill in the art can understand the specific meanings of the above terms in this application according to specific situations.

[0030] This embodiment discloses a coal bunker construction pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com