Heat storage system utilizing heat accumulator to be combined with solid heat storage body

A technology of heat storage system and heat accumulator, applied in the field of heat storage system, can solve the problems of unstable heat source, by-product gas power generation system does not have heat storage function, etc., and achieve the effect of avoiding pollution and maintaining stable power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

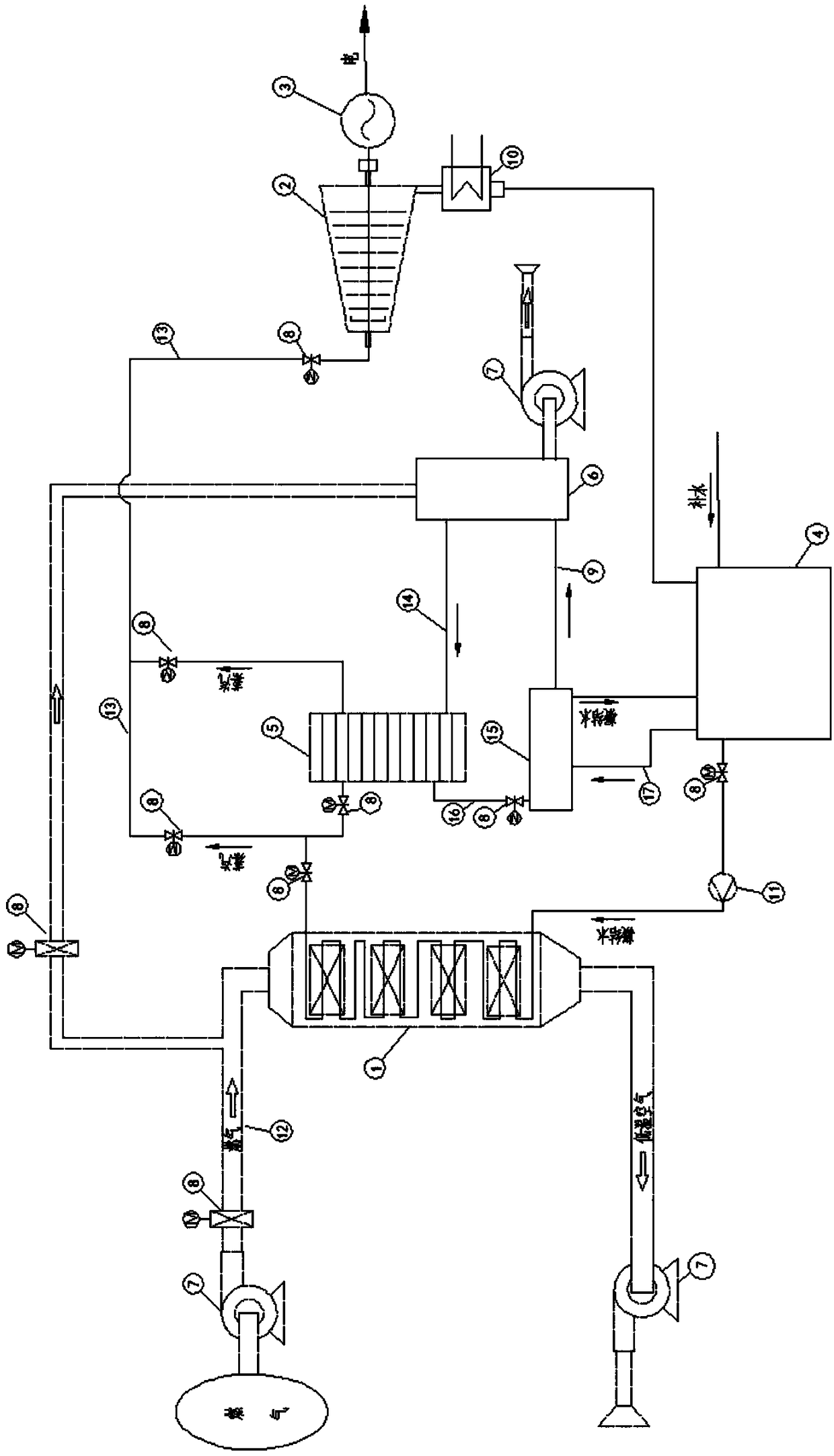

[0023] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0024] The working process of the original power generation system is: the fan 7 transports the gas in the heating medium source pipe 12 to the heat transfer medium generating device 1, and the heat transfer working medium generated by the heat transfer working medium generating device 1 is transported through the heat transfer working medium The pipe 13 is sent to the steam turbine 2, and the steam turbine 2 drives the generator 3 to generate electricity. After the heat loss of the heat transfer medium, it becomes condensed water through the condenser 10 and sent to the condensed water tank 4. The thermal medium generating device 1 forms a cycle.

[0025] The heating medium source pipe 12 is divided into two outputs after passing through the fan 7, one of which is connected to the auxiliary heater 6, and the other is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com