Multifunctional deep water flexible hyperbaric chamber

A multifunctional, hyperbaric chamber technology for strength properties, testing material strength using applied stable tension/compression, testing material strength using applied stable bending force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in combination with specific embodiments.

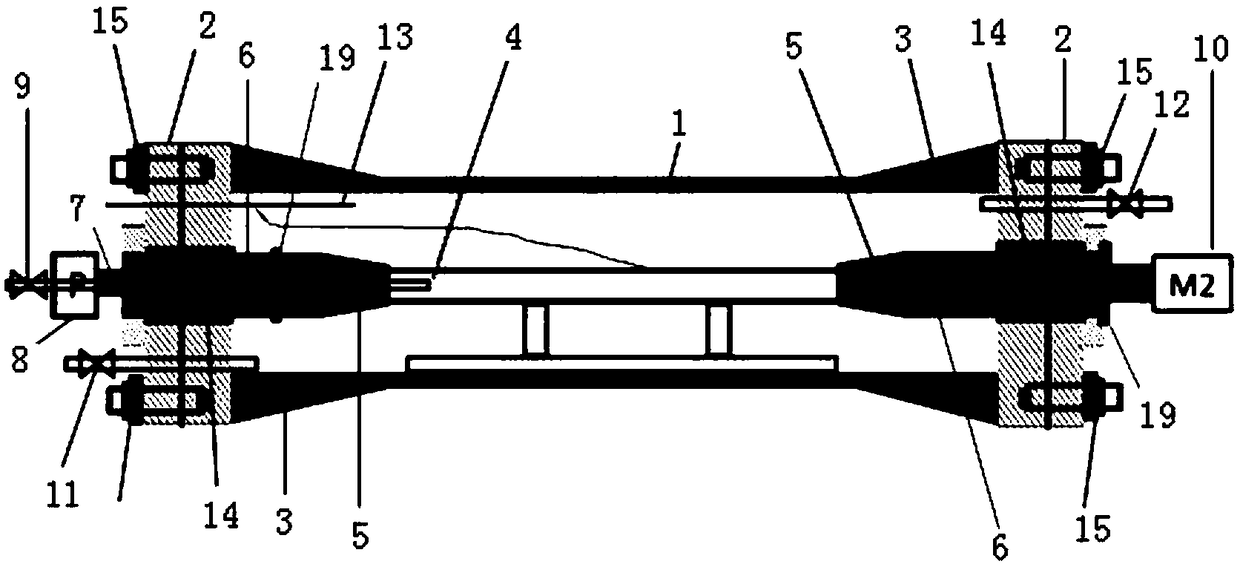

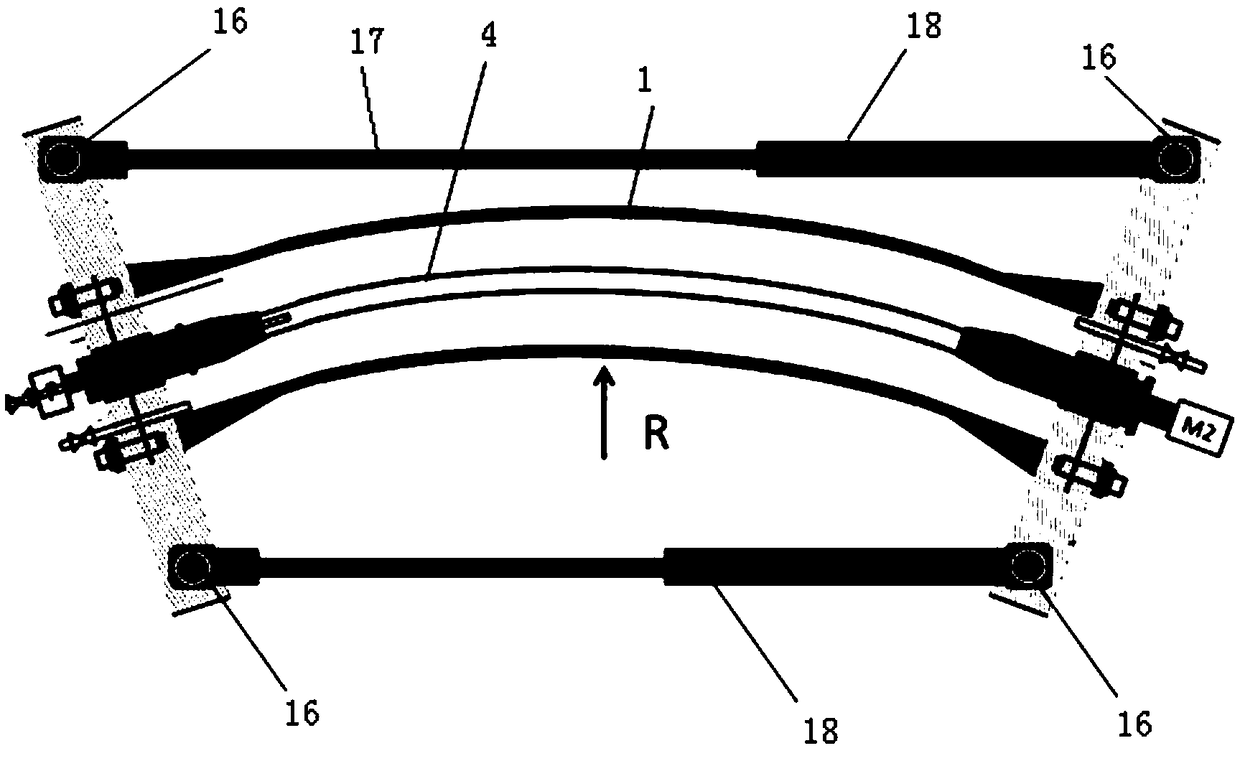

[0013] The present invention is a multifunctional deep water flexible hyperbaric cabin such as figure 1 and figure 2 As shown, it includes a flexible main cylinder 1, end caps 2 are provided at both ends of the flexible main cylinder 1, a first bending reinforcement 3 is provided between the flexible main cylinder 1 and the end cover 2, and the inside of the flexible main cylinder 1 Place the main body 4 of the test piece, and the two ends of the main body 4 of the test piece are respectively connected to the connecting rods 6 through the second bending reinforcement 5, the connecting rods 6 are installed on the end cover 2, and one of the connecting rods 6 is connected through the bearing connector 7 An axial loading mechanism 8 is provided with an internal pressure port 9, another connecting rod 6 is connected to the power drive device 10 through a bearing connector 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com