Non-contact temporary alignment coupler with strip optical fibers

A ribbon optical fiber, non-contact technology, applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of unfavorable construction site use, inconsistent length, time-consuming and laborious cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

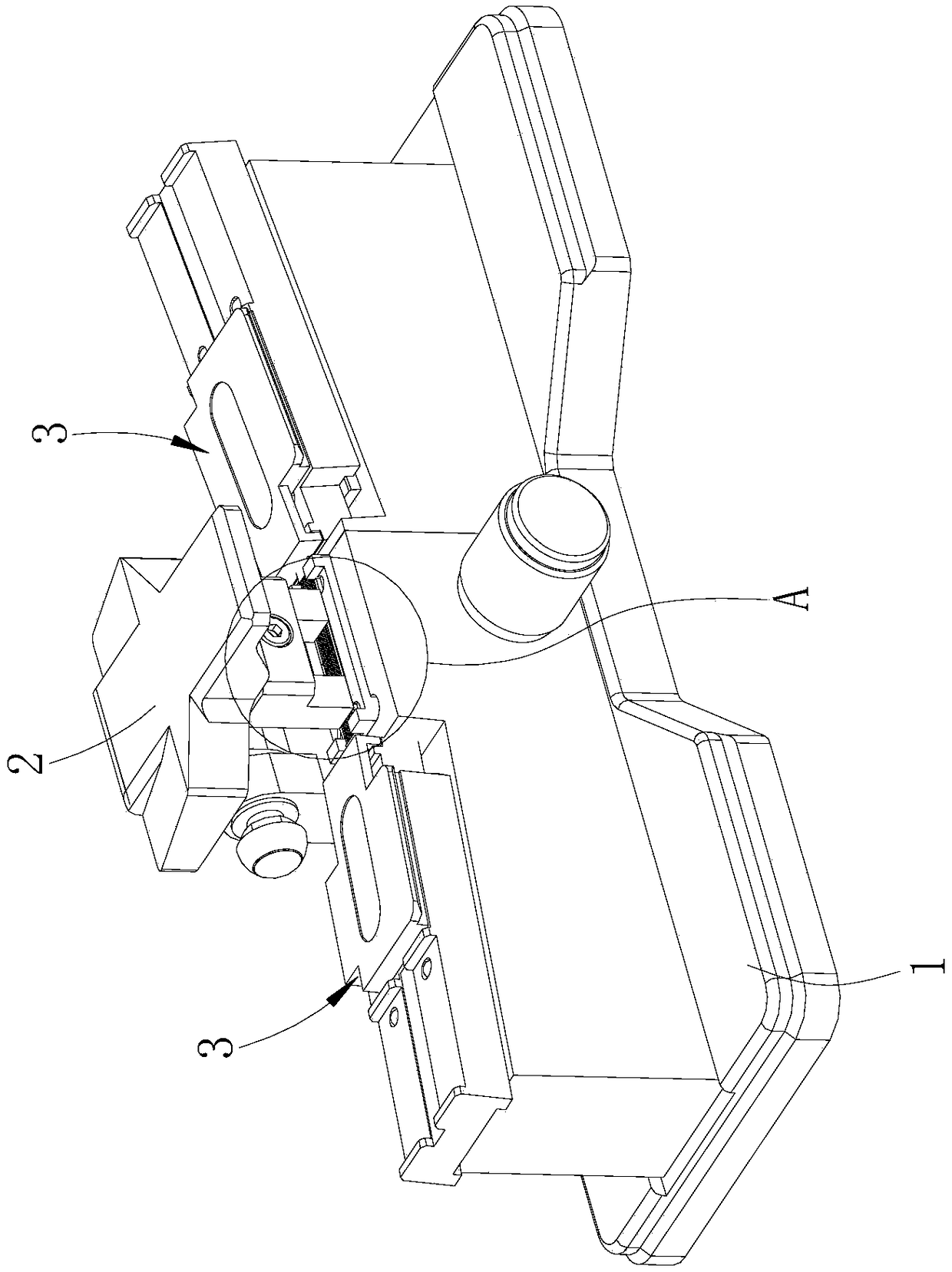

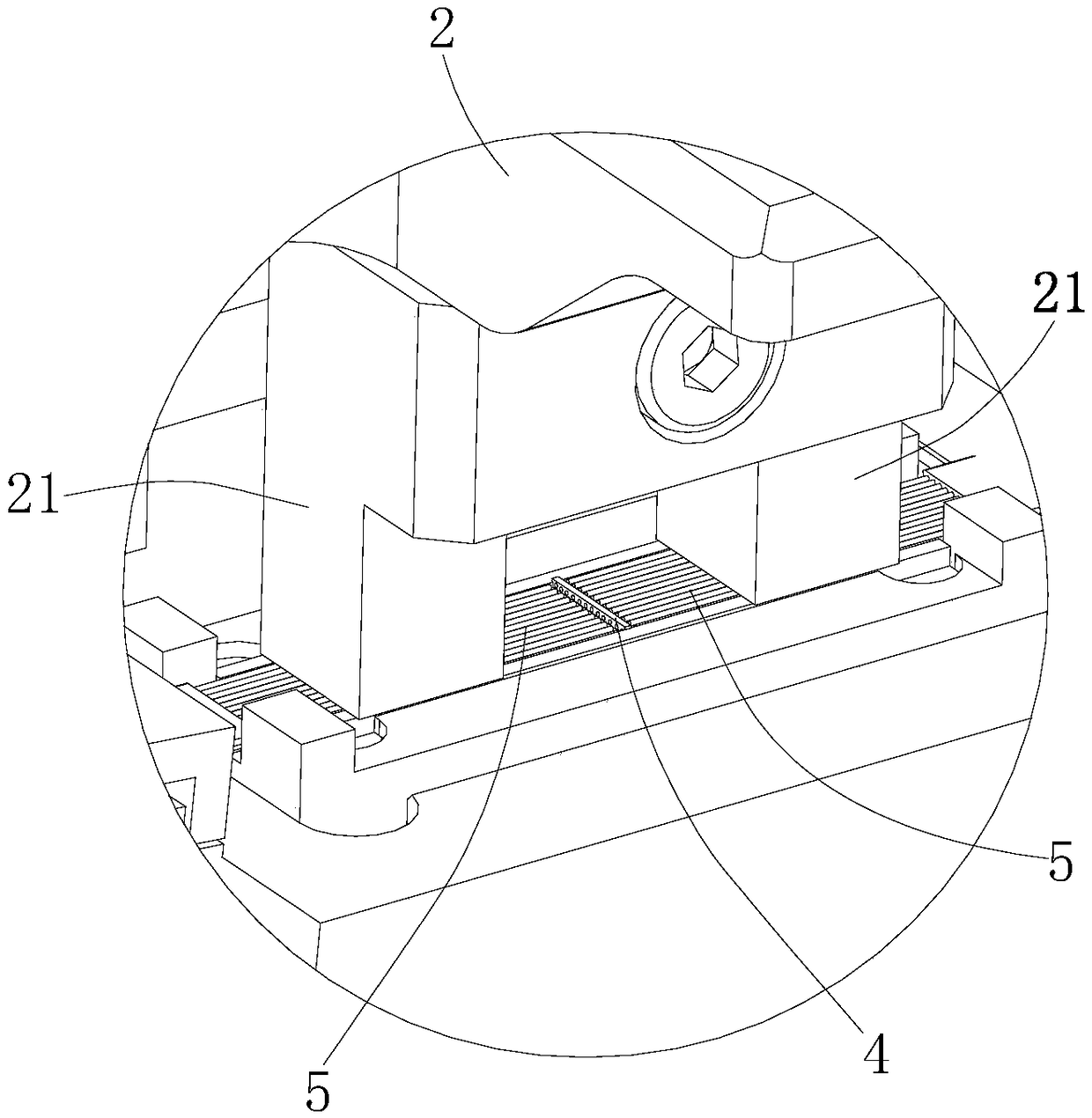

[0015] Such as Figures 1 to 2 shown

[0016] The coupler includes a base 1 , an indenter 2 , a convex lens array and two fiber holders 3 .

[0017] The base 1 is provided with a mirror groove matching the convex lens array and two positioning grooves for placing the ribbon optical fiber 5. The two positioning grooves are distributed left and right respectively. The mirror groove is between the two positioning grooves. The mirror groove communicates with the two positioning grooves. The center lines of the two positioning slots are collinear, and the extension lines of the center lines of the two positioning slots pass through the mirror slot.

[0018] Two optical fiber clamps 3 are fixed on the base 1, and the two optical fiber clamps 3 correspond to the two positioning grooves (the optical fiber clamp 3 includes a seat body and an upper cover, and the seat body is provided with a groove for positioning the ribbon-shaped optical fiber 5, and the upper cover is hinged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com