A multifunctional air conditioner filter element

A multi-functional, filter element technology, applied in air quality improvement, dispersed particle filtration, space heating and ventilation details, etc., can solve problems such as poor antibacterial effect, single function, increase filtration resistance, etc., to achieve better and lasting antibacterial effect. , The effect of increasing the filter area and reducing the running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

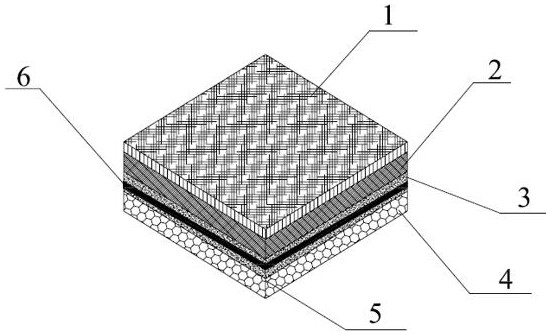

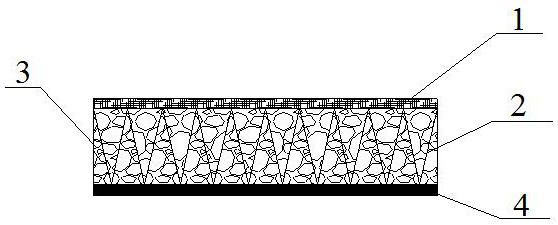

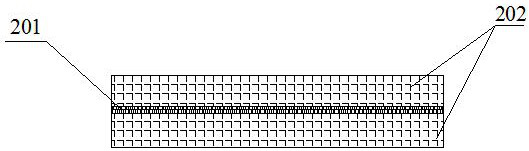

[0023] A multifunctional air conditioner filter element, which sequentially includes an antibacterial coarse filter layer 1, a composite membrane layer 2, a functional particle layer 3, and a particle sealing layer 4 from outside to inside, and the antibacterial coarse filter layer 1 is made of antibacterial modified activated carbon fiber, with a thickness of The antibacterial modified activated carbon fiber is viscose-based activated carbon fiber, the diameter of the antibacterial modified activated carbon fiber is 5 μm, and the antibacterial agent used is an anilide organic antibacterial agent. The composite membrane layer 2 is made by pleating a composite nanofiber membrane, the pleat height is 3cm, and the pleat spacing is 1mm. The composite nanofiber membrane 2 is composed of a membrane layer 201 and a support layer 202. The support layer 202 is located on both sides of the membrane layer 201. The membrane layer is Polytetraethylene nano-scale fiber, fiber diameter 0.05μm...

Embodiment 2

[0025] A multifunctional air conditioner filter element, which sequentially includes an antibacterial coarse filter layer 1, a composite membrane layer 2, a functional particle layer 3, and a particle sealing layer 4 from outside to inside, and the antibacterial coarse filter layer 1 is made of antibacterial modified activated carbon fiber, with a thickness of 5mm, antibacterial modified activated carbon fiber is polyacrylonitrile-based activated carbon fiber, the diameter of antibacterial modified activated carbon fiber is 10μm, and the antibacterial agent used is nano silver inorganic antibacterial agent. The composite membrane layer 2 is made by pleating a composite nanofiber membrane, the pleat height is 20cm, and the pleat spacing is 3mm. The composite nanofiber membrane 2 is composed of a membrane layer 201 and a support layer 202. The support layer 202 is located on both sides of the membrane layer 201. The membrane layer is Made of polyethylene nanoscale fibers, the fib...

Embodiment 3

[0027]A multifunctional air conditioner filter element, which sequentially includes an antibacterial coarse filter layer 1, a composite membrane layer 2, a functional particle layer 3, and a particle sealing layer 4 from outside to inside, and the antibacterial coarse filter layer 1 is made of antibacterial modified activated carbon fiber, with a thickness of 4mm, antibacterial modified activated carbon fiber is phenolic-based activated carbon fiber, the diameter of antibacterial modified activated carbon fiber is 8μm, and the antibacterial agent used is chitin biological antibacterial agent. The composite membrane layer 2 is made by pleating a composite nanofiber membrane, the pleat height is 10cm, and the pleat spacing is 2mm. The composite nanofiber membrane 2 is composed of a membrane layer 201 and a support layer 202. The support layer 202 is located on both sides of the membrane layer 201. The membrane layer is Made of polyester nanoscale fibers, the fiber diameter is 1 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com