Three-dimensional model data conversion device with 3D control unit

A technology for controlling units and 3D models, applied in the field of 3D printing, can solve problems such as cumbersome use steps, damage to electronic components, and displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

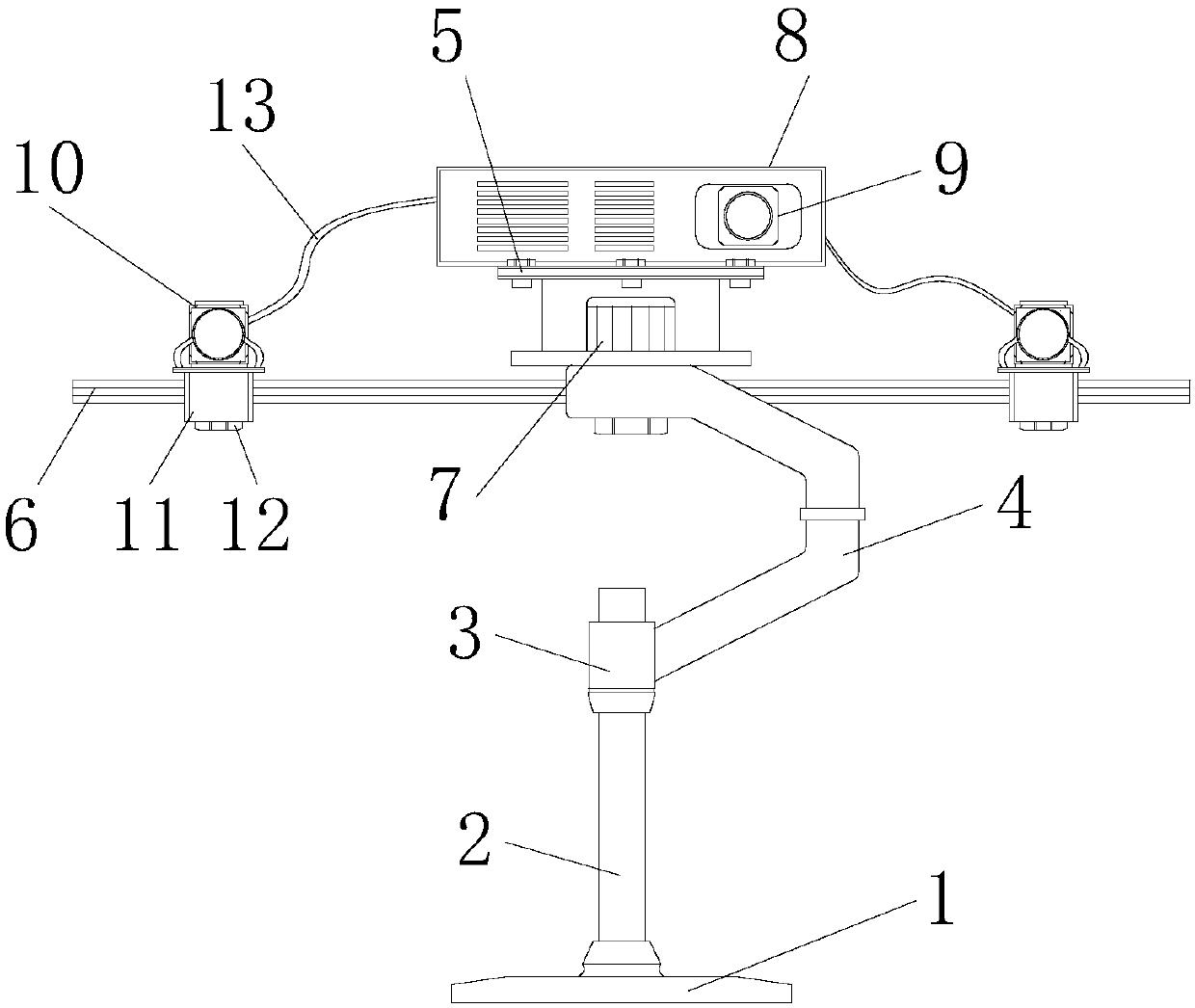

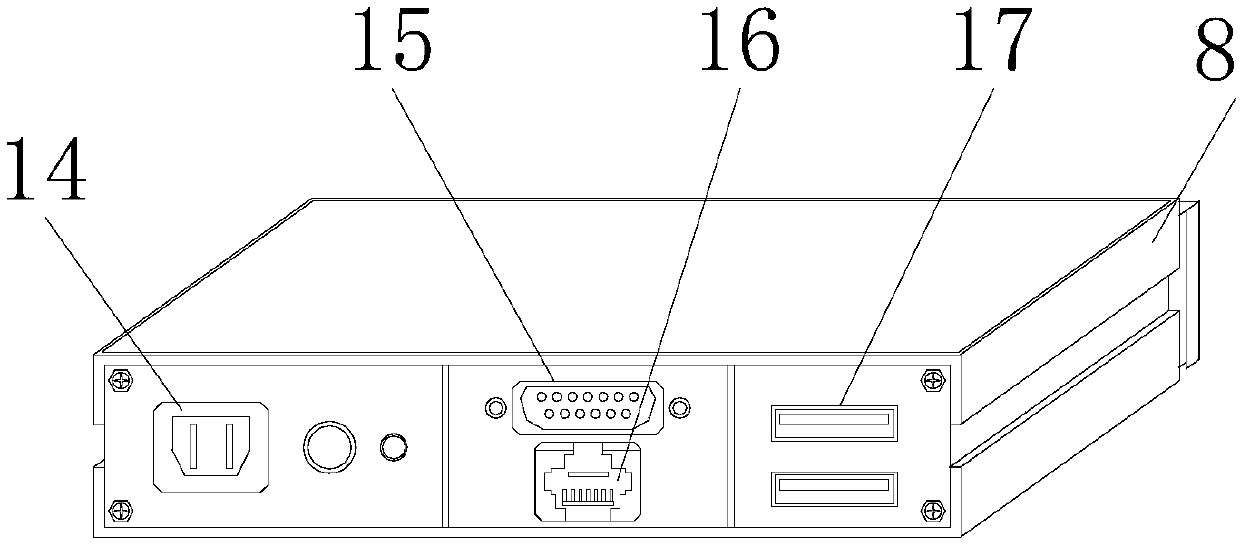

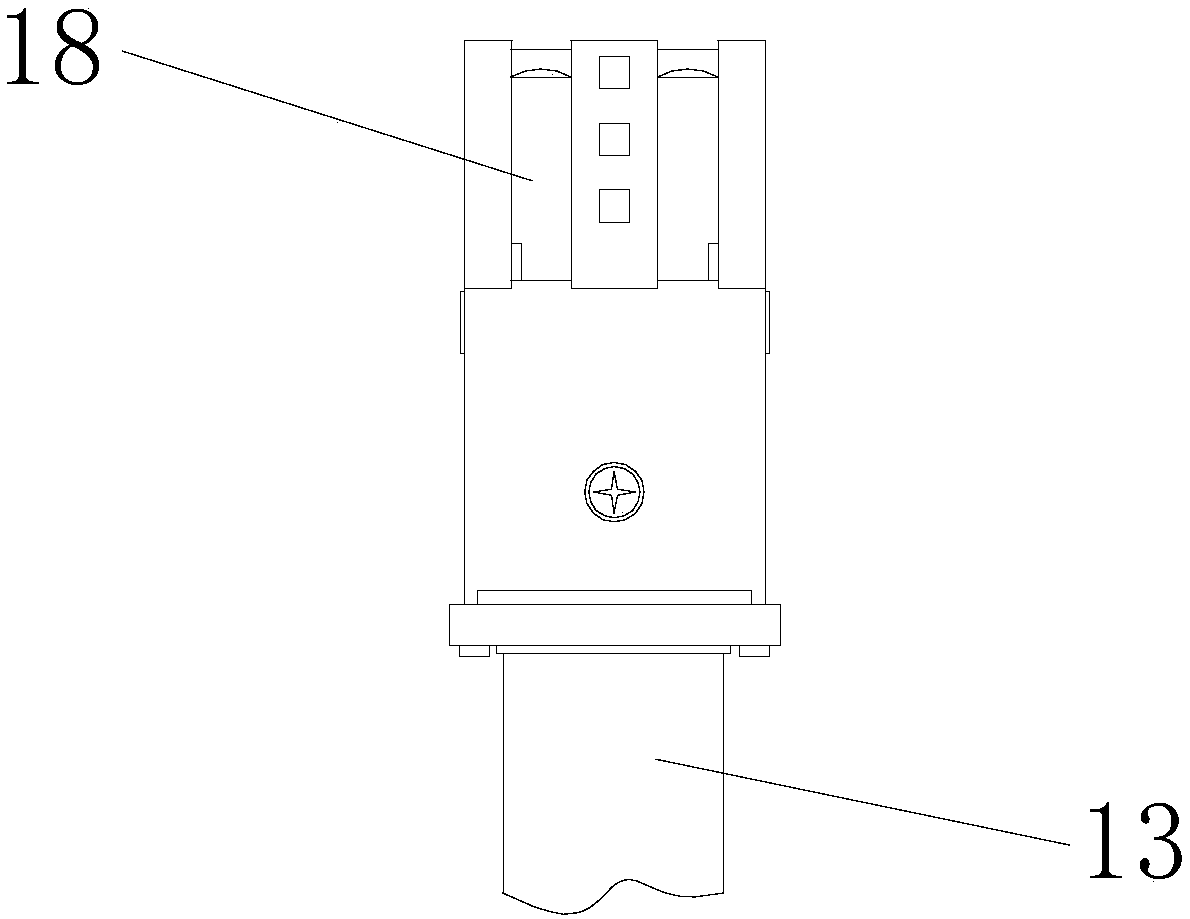

[0028] see Figure 1-3 , the present invention provides the following technical solutions: a three-dimensional model data conversion device with a 3D control unit, comprising a base 1, the top of the base 1 is welded with a column 2, the outer wall of the column 2 is provided with a rotating collar 3, and the rotating collar The outer wall of the 3 is welded with a force arm 4, the force arm 4 and the column 2 are rotationally connected by the rotating collar 3, the back of the force arm 4 is screwed with a horizontal slide rail 6, and the horizontal slide rail 6 is provided with a sliding seat 11, and the sliding seat 11 Slidingly connected with the horizontal slide rail 6, the bottom of the sliding seat 11 is provided with a pin 12, the sliding seat 11 and the horizontal slide rail 6 are fixed by the pin bolt 12, and the top of the sliding seat 11 is fixed with the auxiliary camera 10 by clamps and screws. The top of 4 is screwed to the rotary table 5, and the inside of the ...

Embodiment 2

[0049] The difference from Example 1 is that the surface of the motor 7 is coated with an antistatic layer, and the preparation method of the antistatic layer is:

[0050] Take the following components by weight for later use: 10 parts of polyurethane prepolymer, 5 parts of polyacrylamide, 7 parts of methyl benzoylformate, 8 parts of sodium alkylsulfonate, 33 parts of epoxy resin, butyl fiber 1 part plain, 11 parts bentonite, 2 parts carbon black, 13 parts talcum powder, 1 part aminoethylpiperazine, 21 parts copper powder.

[0051] S1. Add the epoxy resin into the dispersing tank, add butyl cellulose and methyl benzoylformate in sequence under stirring at 450r / min, and stir for 3 minutes;

[0052] S2. After increasing the rotating speed to 950r / min, after adding sodium alkylsulfonate and polyacrylamide in sequence, increase the rotating speed again to 2000r / min and disperse at this rotating speed for 15min, and then detect until the system fineness≤60;

[0053] S3. Add polyur...

Embodiment 3

[0057] The difference from Example 2 is that the specific gravity of the formula has been modified, and the modified formula is:

[0058] Take the following components by weight for subsequent use: 12 parts of polyurethane prepolymer, 6 parts of polyacrylamide, 10 parts of methyl benzoylformate, 9 parts of sodium alkylsulfonate, 46 parts of epoxy resin, butyl fiber 3 parts of plain, 13 parts of bentonite, 5 parts of carbon black, 14 parts of talcum powder, 2 parts of aminoethylpiperazine, and 23 parts of copper powder.

[0059] S1. Add the epoxy resin into the dispersing tank, add butyl cellulose and methyl benzoylformate in sequence under stirring at 450r / min, and stir for 3 minutes;

[0060] S2. After increasing the rotating speed to 950r / min, after adding sodium alkylsulfonate and polyacrylamide in sequence, increase the rotating speed again to 2000r / min and disperse at this rotating speed for 15min, and then detect until the system fineness≤60;

[0061] S3. Add polyuretha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com