Single-face and double-face automatic film pasting machine and film pasting technology thereof

A film laminating machine, single-sided and double-sided technology, which is applied in the field of single- and double-sided automatic laminating machine and its laminating process, and can solve the problems of automatic export, peeling and taking out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with accompanying drawing:

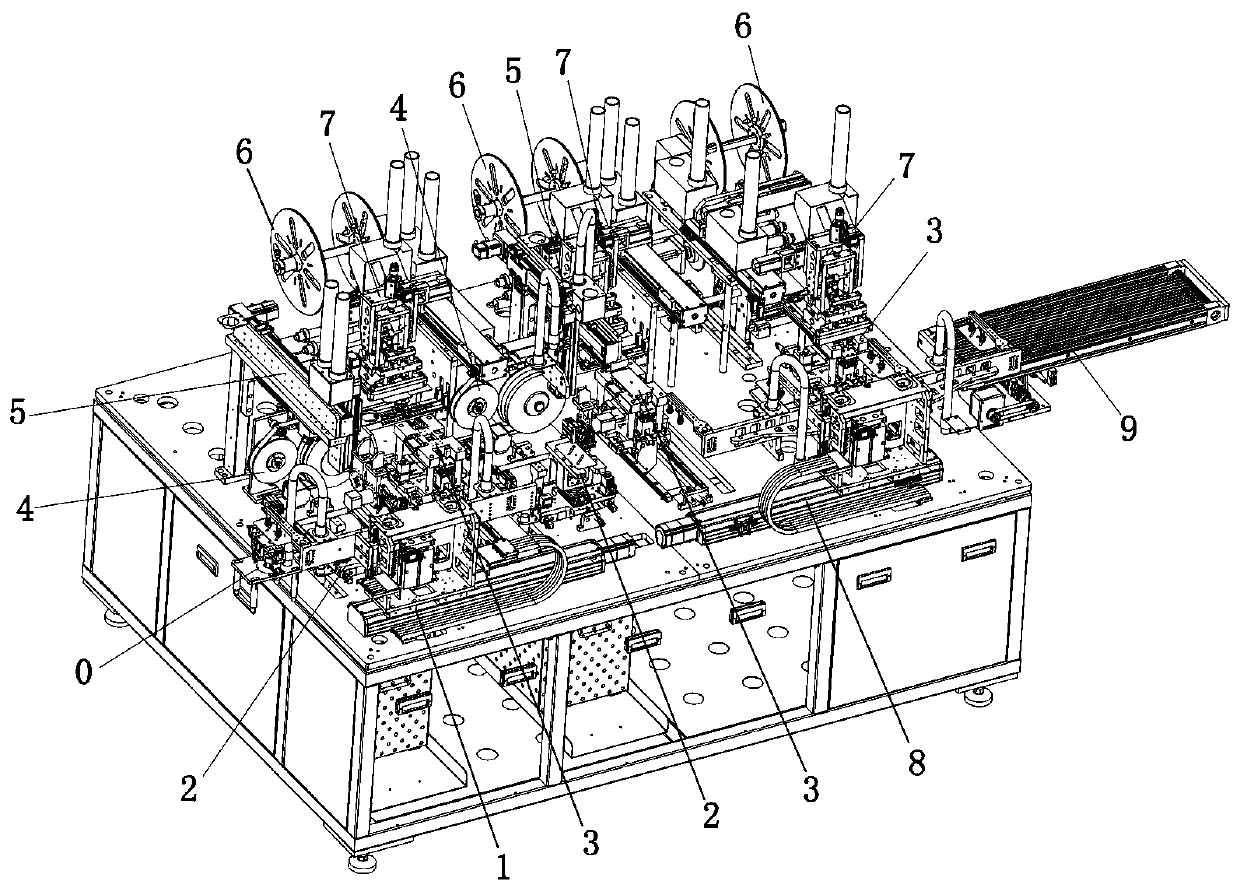

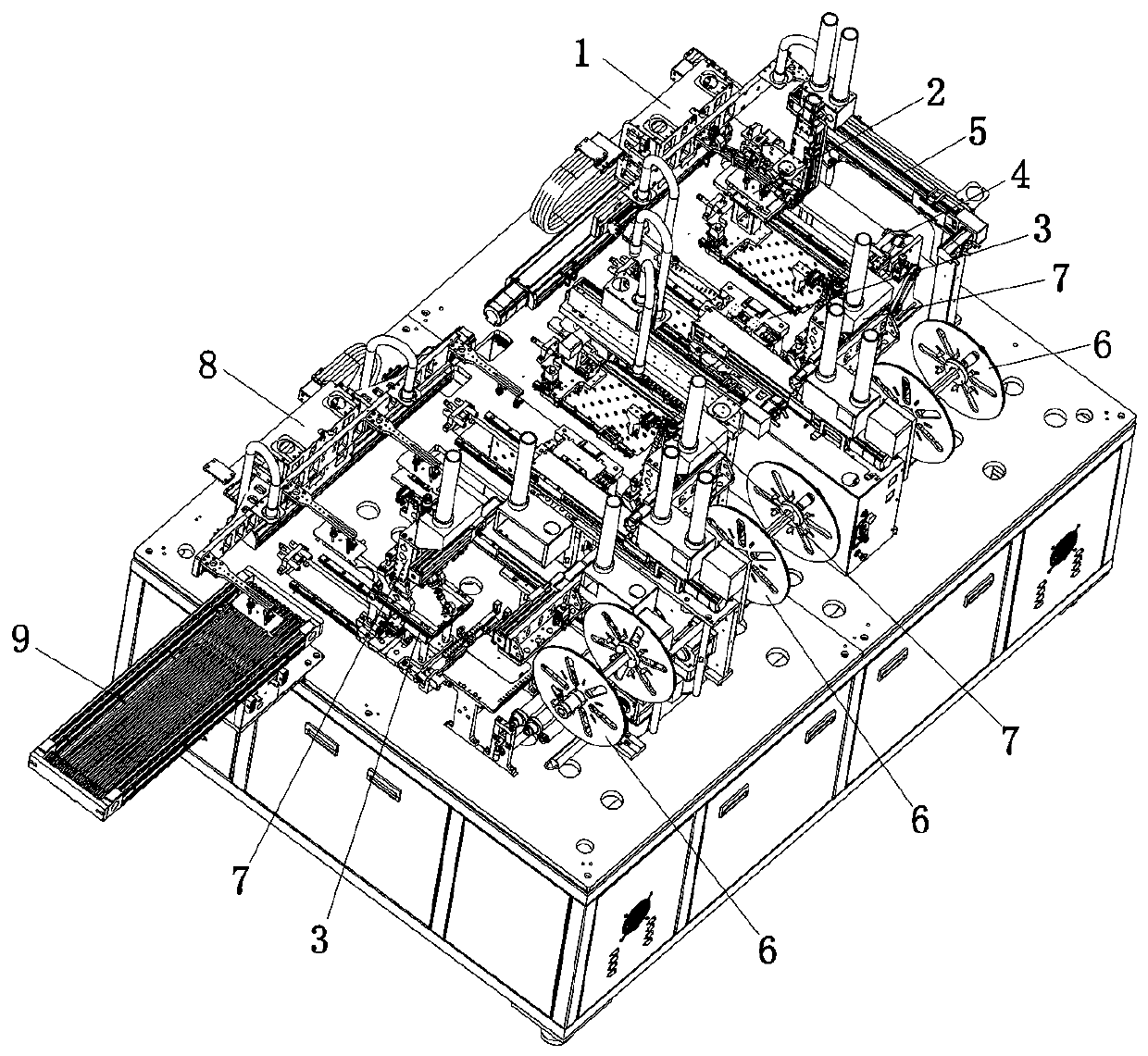

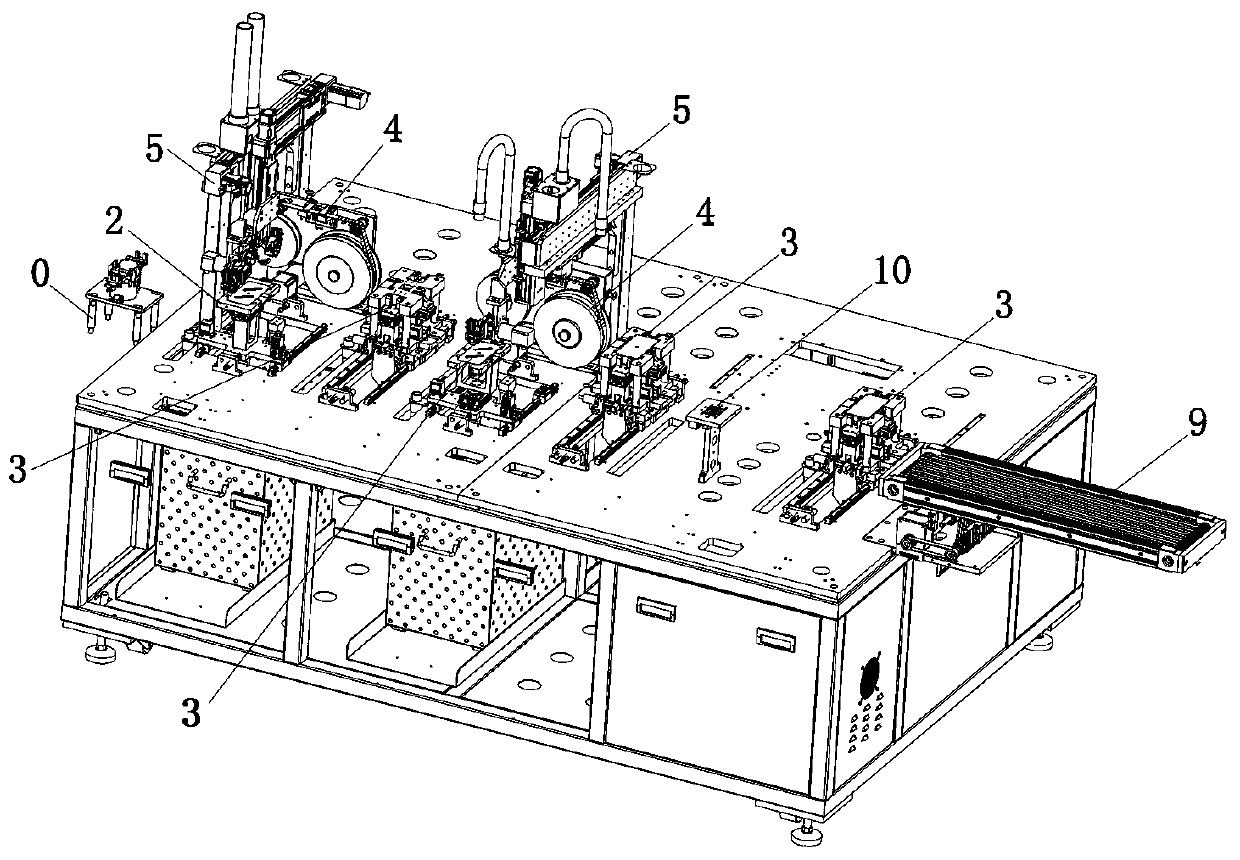

[0060] Such as Figure 1 to Figure 23 As shown, the technical scheme adopted by the present invention is as follows: a single- and double-sided automatic film laminating machine, comprising a first linkage manipulator 1, a film tearing platform 2, a film laminating platform 3, an easy-to-tear and paste export mechanism 4, a tear and paste mechanism 5, a film taking And placement mechanism 6 and second linkage manipulator 8, wherein, above-mentioned tearing film platform 2 comprises two, and two tearing film platforms 2 intervals are arranged on the frame 1; Above-mentioned film sticking platform 3 comprises three, and three film sticking platforms 3 successively The interval is set at the rear of the first two tearing film platforms 2, the third film sticking platform 3 is set at the rear of the second film sticking platform 3 at intervals, and a transfer platform 10 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com