Wavy electromagnetic wave absorbing concrete structure based on 3 D printing

A technology of concrete structure and electromagnetic wave absorption, which is applied in the field of concrete, can solve the problems of large direct electromagnetic wave reflection on the surface, low electromagnetic wave absorption capacity of the surface layer, and inability to reflect electromagnetic waves multiple times, so as to achieve a high degree of automation, reduce reflected electromagnetic waves, and increase The effect of the number of reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

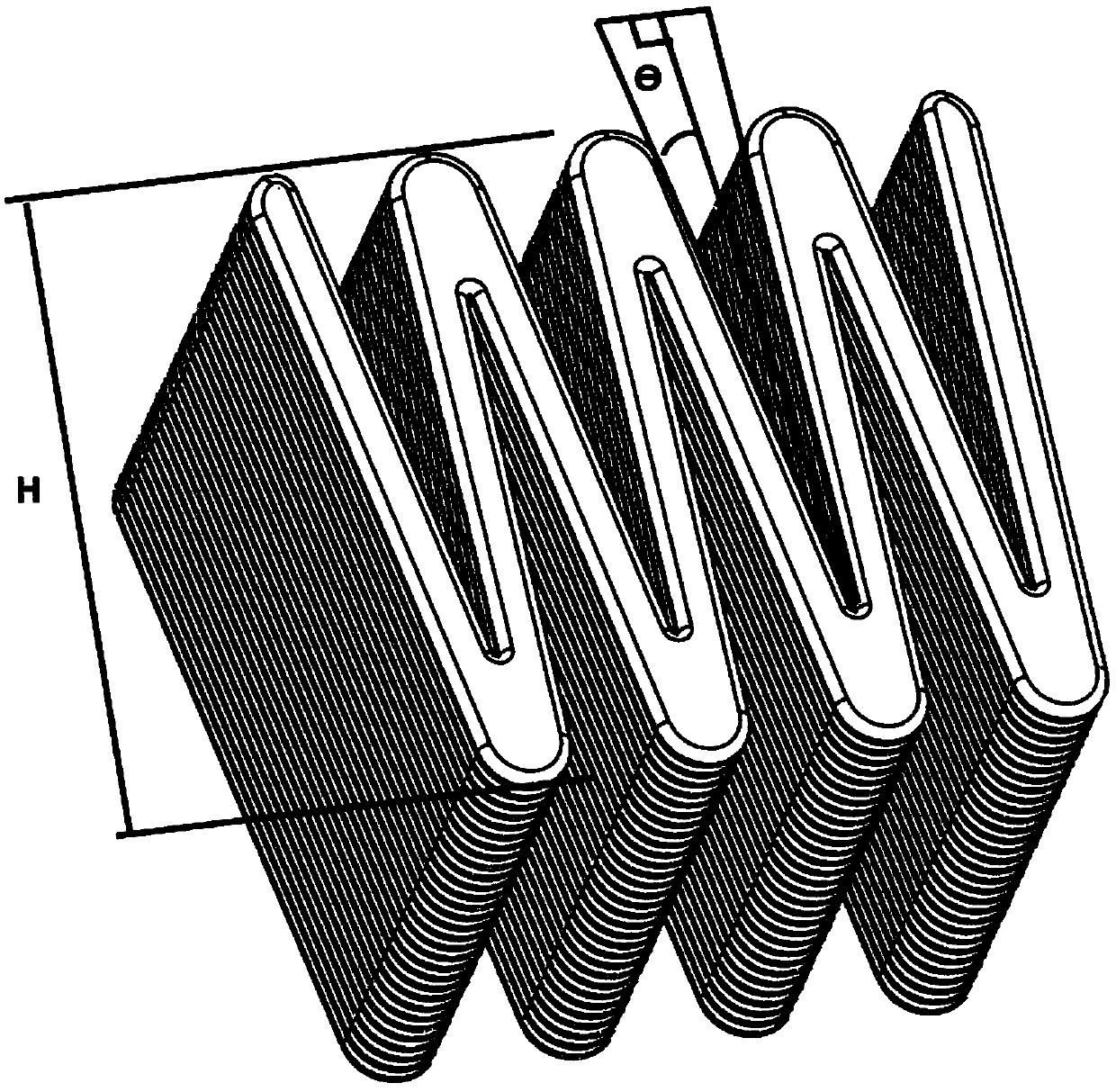

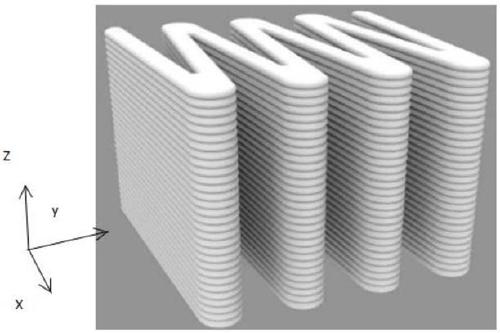

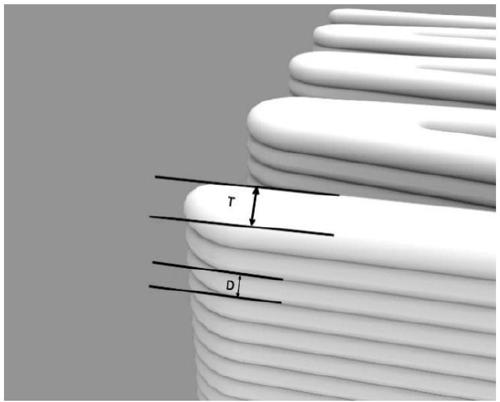

[0035]In the wave-shaped electromagnetic wave-absorbing concrete structure based on 3D printing in this embodiment, the distance H from the highest point to the lowest point of the horizontal wave shape is 45mm, D is 5.5mm, T is 12mm, K is 2.5mm, Tanθ is 1, that is, θ is 45°. Pump or mechanically transport the concrete slurry into the print nozzle of the 3D printer, and let it stand for 5 minutes. The rest time refers to the time between the preparation of the concrete and the start of printing. Set the outlet cross-sectional area of the print nozzle to 120mm 2 , the horizontal printing speed is 175cm / min, the vertical printing speed is 0.7m / h, and the extrusion speed is 0.02m 3 / h then prints.

[0036] In this example, the concrete in the wave-shaped electromagnetic wave-absorbing concrete structure based on 3D printing is 3D-printable copper slag electromagnetic wave-absorbing concrete. The composition and content of the concrete are as follows in parts by weight:

[003...

Embodiment 2

[0060] Such as Figure 6 As shown, in the wave-shaped electromagnetic absorbing concrete structure based on 3D printing in this embodiment, H is 45mm, D is 5mm, T is 14mm, K is 1.8mm, and Tanθ is 2 / 3. The concrete is pumped or mechanically transported into the print head of the 3D printer, and the rest time is 7 minutes. The rest time refers to the time between the preparation of the concrete and the start of printing. The outlet cross-sectional area of the print head is set to 150mm 2 , the horizontal printing speed is 170cm / min, the vertical printing speed is 0.6m / h, and the extrusion speed is 0.05m 3 / h, and then print.

[0061] In this example, the concrete in the wave-shaped electromagnetic wave-absorbing concrete structure based on 3D printing is 3D-printable copper slag electromagnetic wave-absorbing concrete. The composition and content of the concrete are as follows in parts by weight:

[0062] 6.8 parts of 42.5# rapid hardening ordinary Portland cement;

[0063]...

Embodiment 3

[0085] Control 3D printed copper slag electromagnetic absorbing concrete, H is 90mm, D is 5.2mm, T is 15mm, K is 2mm, and Tanθ is 1 / 3. The concrete is pumped or mechanically transported to the print nozzle of the 3D printer, and the rest time is 6 minutes. The rest time refers to the time between the preparation of the concrete and the start of printing. The outlet cross-sectional area of the print nozzle is set to 160mm 2 , the horizontal printing speed is 180cm / min, the vertical printing speed is 0.6m / h, and the extrusion speed is 0.02m 3 / h, and then print.

[0086] In this embodiment, the copper slag electromagnetic wave-absorbing concrete that can be printed in 3D is calculated in parts by weight, and the composition and content of the concrete are respectively:

[0087] 7.1 parts of 42.5# rapid hardening ordinary Portland cement;

[0088] 7.1 parts of quartz sand;

[0089] 1.75 parts of copper slag;

[0090] 0.85 parts of silica fume;

[0091] 0.18 parts of water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com