Production method of 15CrMoR steel plates for equipment in hydrogen service

A production method and hydrogen-facing equipment technology, applied in the field of steelmaking, can solve the problems of difficult production process control and large width of the steel plate used for the head, and achieve the effects of excellent performance, stable low-temperature impact performance, and large margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

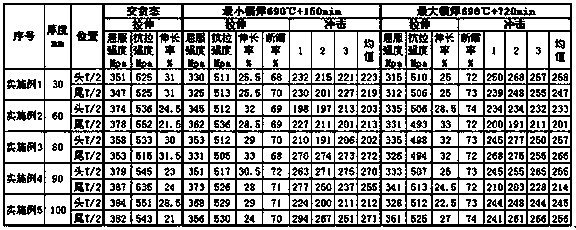

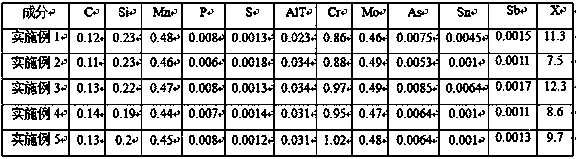

[0019] The embodiment is a 15CrMoR steel plate with a thickness of 16 mm to 100 mm, which is used for hydrogenation equipment with guaranteed performance and flaw detection. The weight percentage of the chemical composition of the steel is shown in Table 1. The production process is converter smelting→LF refining→VD vacuum treatment→continuous casting→slab heating→controlled rolling→online cooling→heat treatment. In the converter smelting, ensure that the tapping carbon is ≥ 0.05%, the tapping P is ≤ 0.006%, and the tapping temperature is ≥ 1580°C; avoid slag during the tapping process; in the LF refining, ensure that the white slag retention time is controlled at More than 20min, before the LF furnace exits the station, carry out secondary P removal, P≤0.004%; in the vacuum refining, the vacuum holding time at ≤67Pa is ≥23min, and calcium treatment is carried out after the VD is broken; in the continuous casting In the continuous casting, the cross-section is 260mm or 300mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com