Production method of rotating target

A production method and technology of rotating targets, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of insufficient connection strength between the metal binding layer, the metal back tube and the target material, and avoid temperature too low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

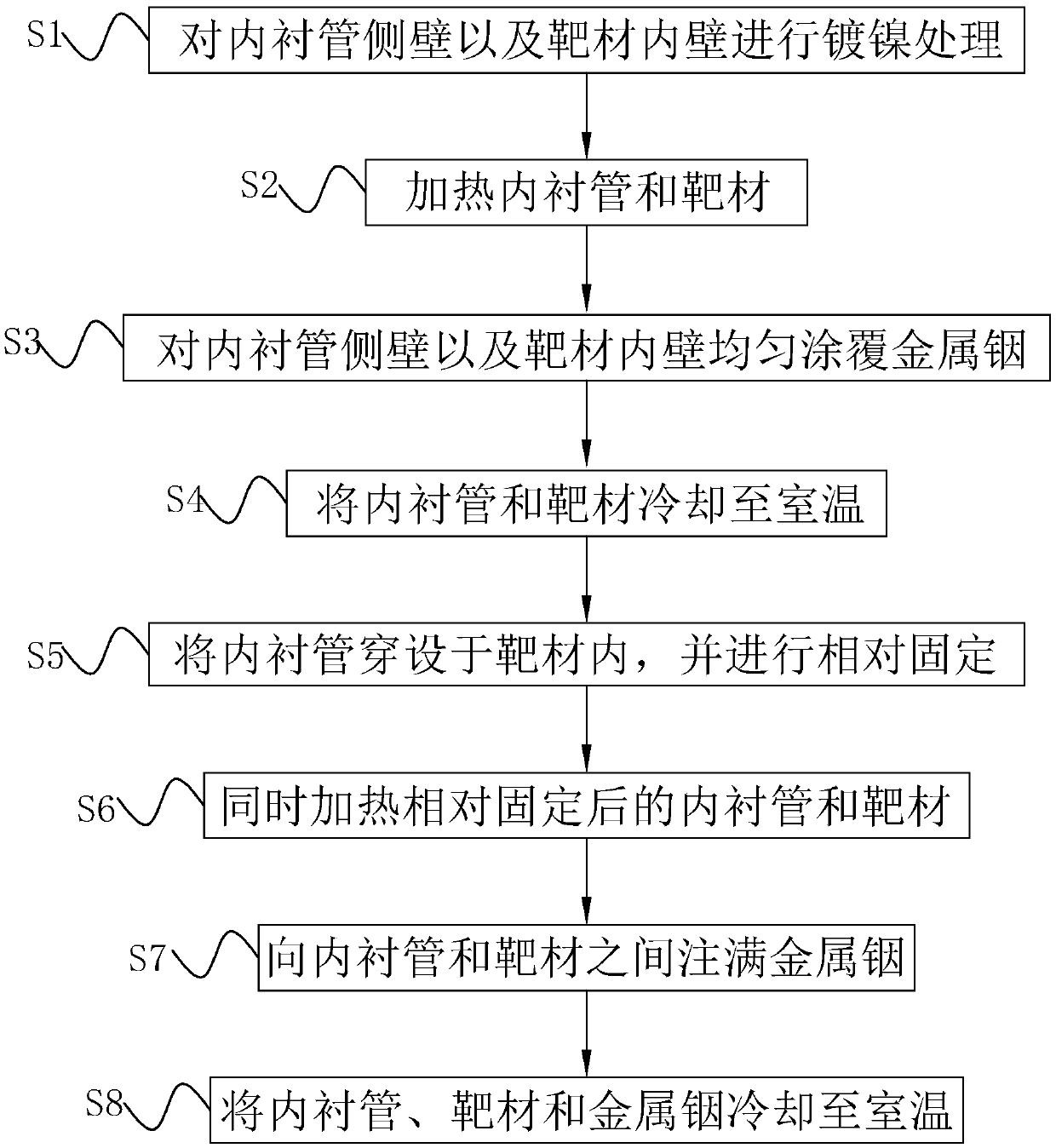

[0037] Such as figure 1 Shown, a kind of production method of rotating target comprises the steps:

[0038] Step S1: Perform pre-nickel plating on the side wall of the lining pipe and the inner wall of the target material, the nickel material is impact nickel, and the thickness is 100um, and conduct a tape test to check whether it is qualified;

[0039] Step S2: Put the lining pipe and the target material into a hot air circulation furnace for heating, and the heating temperature is between 150°C and 190°C;

[0040] Step S3: Evenly coat the side wall of the liner tube and the inner wall of the target with metal indium; measure the temperature of the liner tube and the tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com