Batten-plate-type cold-formed thin-walled trapezoidal section lattice steel column

A technology of cold-formed thin-walled, latticed steel, applied in the direction of columns, piers, pillars, etc., can solve the problems of no systematic experimental research, inability to realistically simulate boundary conditions, and no theoretical framework, and improve the bearing capacity. , the effect of improving stability, ductility and seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

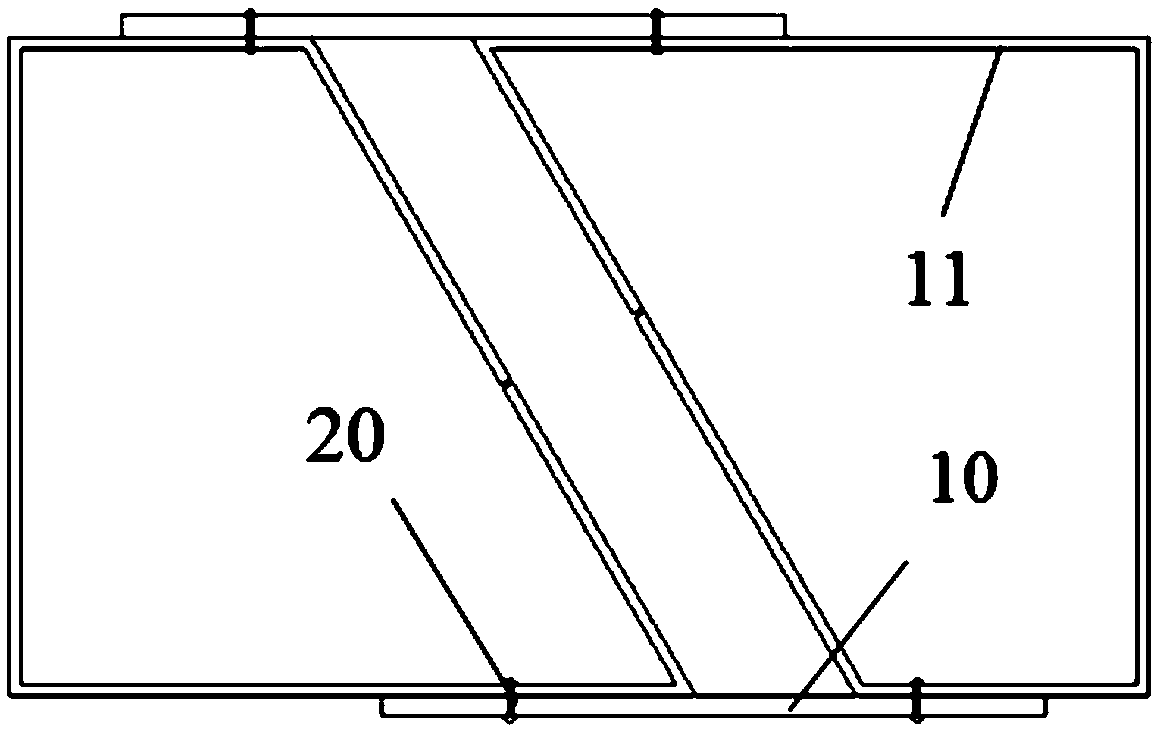

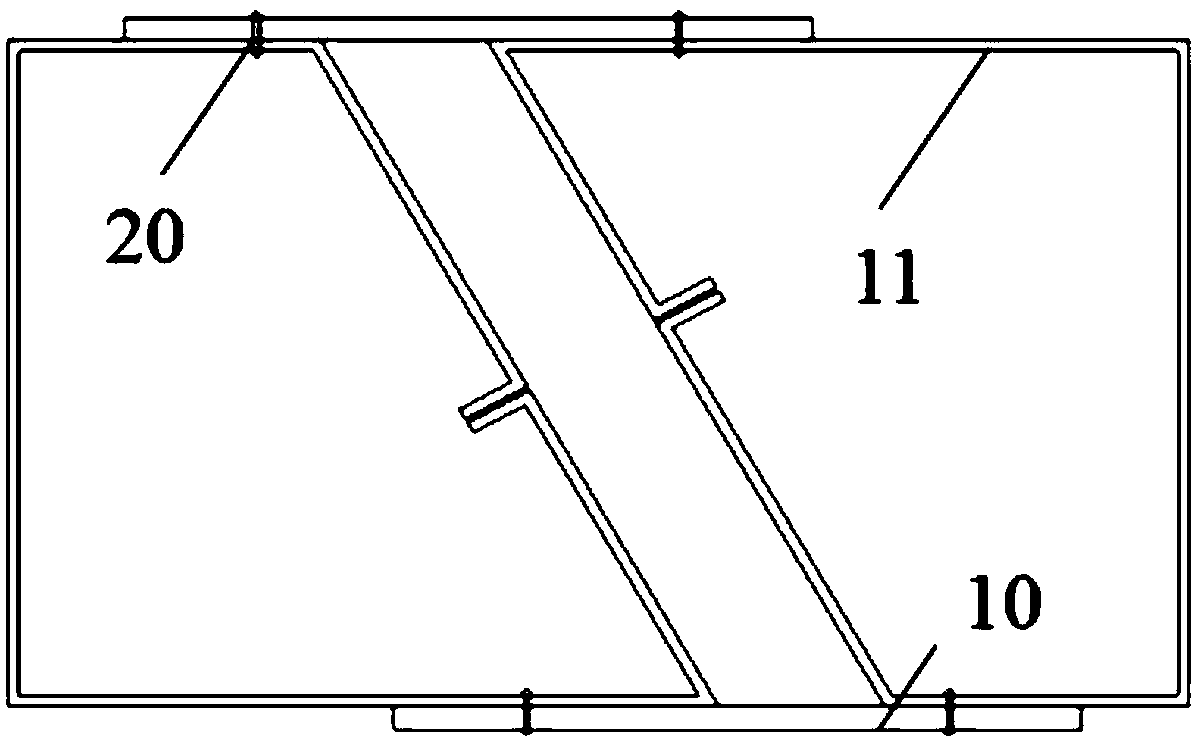

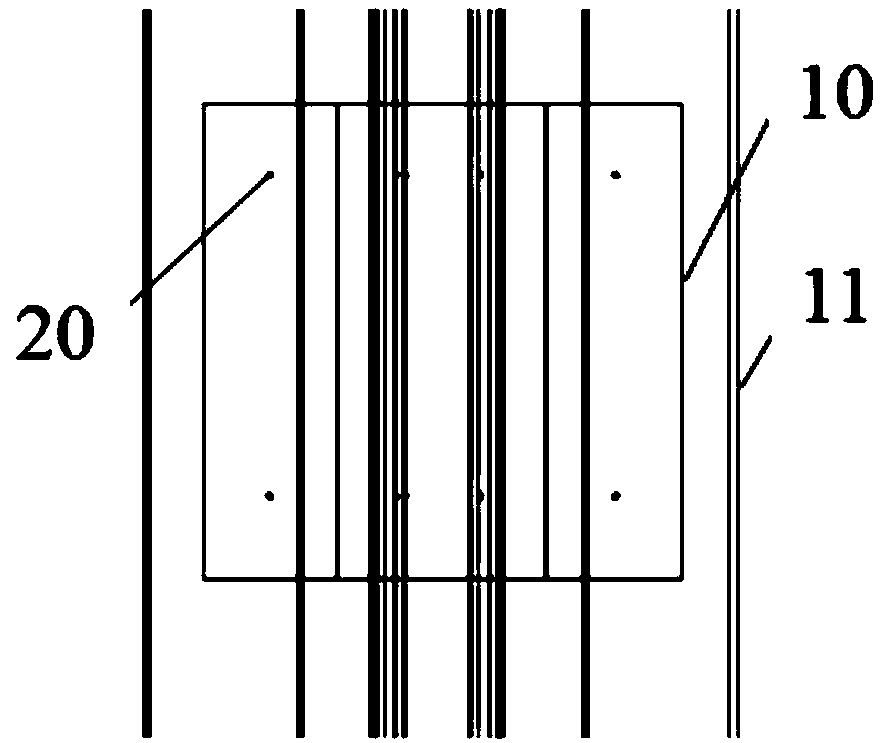

[0022] The following is a clear and complete description of the technical solutions of the embodiments of the present invention in conjunction with the accompanying drawings of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

[0023] It should be understood that in the current steel structure design of industrial and civil buildings in my country, due to the flexible structure of cold-formed thin-walled steel section and better mechanical performance, it is used in low-rise steel structure residences, offices, temporary structures, light steel workshops, and villas. structures have been widely used. At present, cold-formed thin-walled composite columns are mainly divided into singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com