Double-source type high-temperature heat pump drying equipment

A high-temperature heat pump and drying equipment technology, applied in lighting and heating equipment, drying, dryers, etc., can solve the problems of only reaching 70°C, limited air outlet temperature, environmental pollution, etc., to avoid dust and Pollution, guaranteed drying quality, and high comprehensive energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

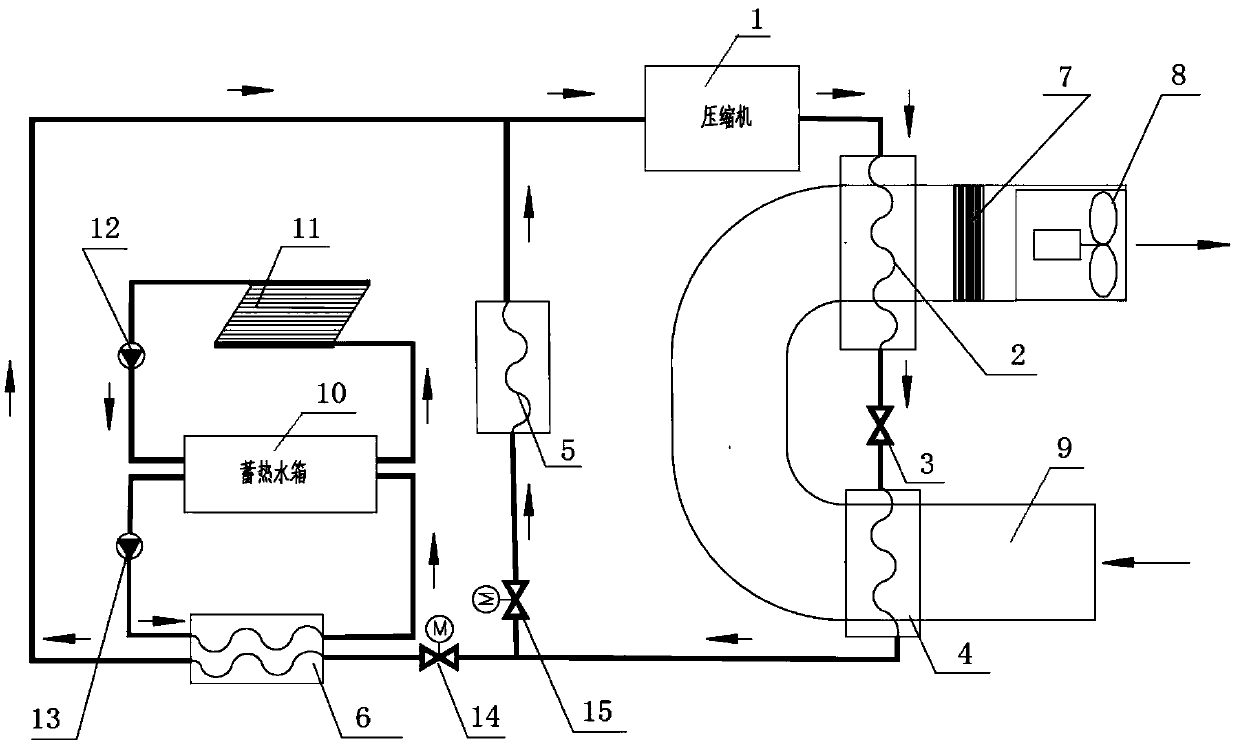

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

[0022] see figure 1 , the best embodiment of the present invention, a dual-source high-temperature heat pump drying equipment, including a compressor 1, a condenser 2, a throttle valve 3, a primary evaporator 4, a finned heat exchanger 5, a shell-and-tube Type heat exchanger 6, ventilation pipe 9, PTC ceramic heater 7, air blower 8, solar heat collector 11, solar hot water circulation pump 12, circulation heating pump 13, hot water storage tank 10, first electric valve 14 And the second electric valve 15.

[0023] The outlet of compressor 1, condenser 2, throttle valve 3, primary evaporator 4, first electric valve 14, shell-and-tube heat exchanger 6 and the inlet of compressor 1 are connected through pipelines in sequence; the primary evaporator 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com