Refrigeration/heat pipe composite cabinet air conditioning system and control method thereof

A technology of cabinet air conditioning and control method, applied in the direction of cooling/ventilation/heating transformation, can solve the problems of complex system design, high material cost, many copper pipe branches, etc., and achieves reduced operating costs, simple pipelines, and energy consumption. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

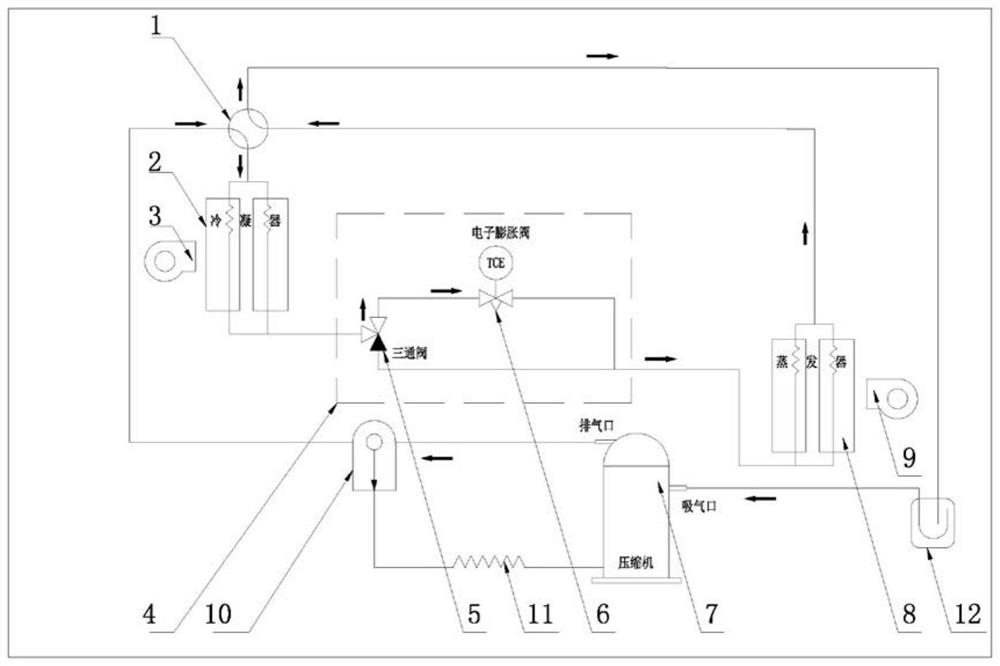

[0031] like Figure 1-5 shown, in the illustration, assembled from the following components:

[0032]

[0033]

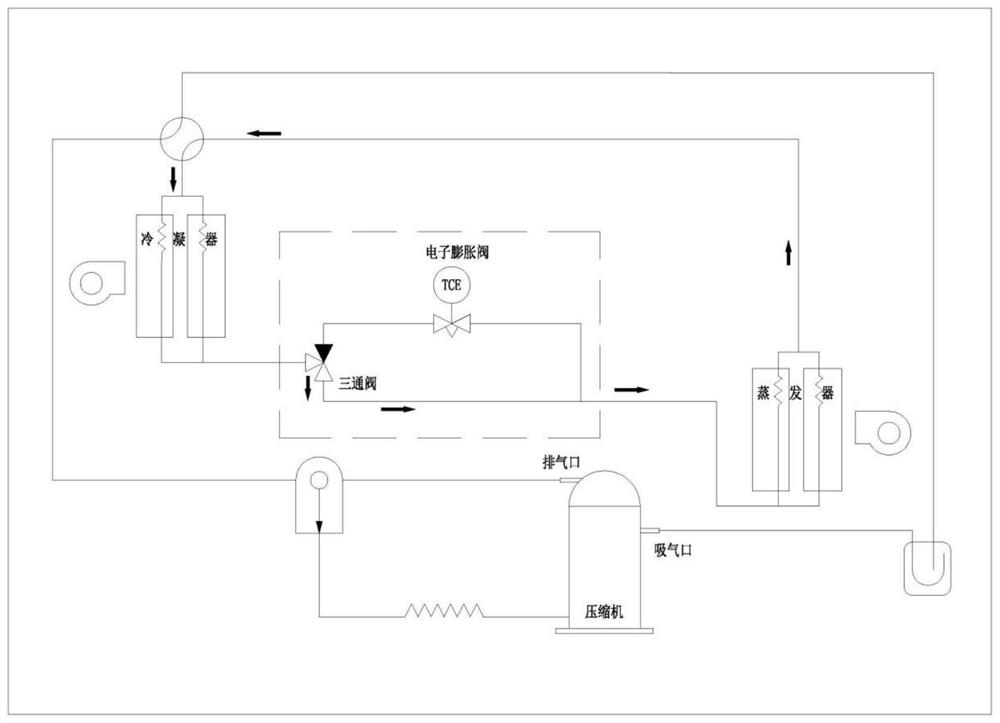

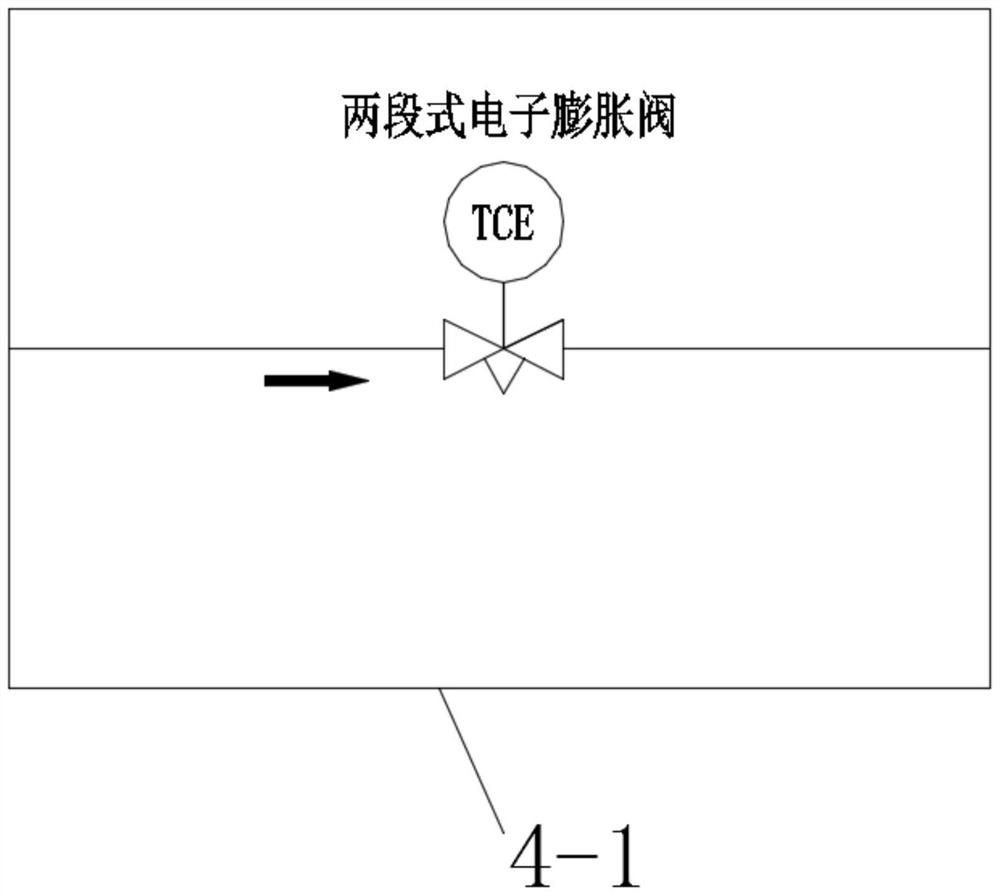

[0034] Assembly instructions: Install the condenser 2, the external circulation fan 3, the throttle variable mechanism 4, the three-way valve 5, the electronic expansion valve 6, the compressor 7, the evaporator 8 and the inner circulation fan 9 inside the cabinet shell, and then Install the refrigeration system connecting pipeline, the controller and the four-way valve 1 inside the cabinet shell, and connect the refrigeration system connecting pipeline to the exhaust port of the compressor 7, the inlet of the condenser 2, and the evaporator 8 through the four-way valve 1 respectively. The outlet of the three-way valve 5 and the suction port of the compressor 7 are connected to the outlet of the condenser 2 through the pipeline, and one outlet of the three-way valve 5 is connected in series to the inlet of the evaporator 8 by the electronic expansion valve 6. ...

Embodiment 2

[0036] like Figure 1-5 shown, in the illustration, assembled from the following components:

[0037]

[0038]Assembly instructions: Install the condenser 2, the external circulation fan 3, the throttling variable mechanism 4, the compressor 7, the evaporator 8, the internal circulation fan 9, the oil separator 10 and the gas-liquid separator 12 inside the cabinet shell, and then Install the refrigeration system connecting pipeline, controller and four-way valve 1 inside the cabinet shell, and connect the refrigeration system connecting pipeline through the four-way valve 1 to the air outlet of the oil separator 10, the inlet of the condenser 2, and the evaporator 8 respectively. The outlet of the oil separator 10 and the inlet of the gas-liquid separator 12, the air outlet of the oil separator 10 and the exhaust port of the compressor 7 are connected by pipelines, the oil return port of the oil separator 10 and the compressor 7 are connected by the oil return capillary 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com