A battery appearance defect detection method based on dimension reduction and point cloud data matching

A technology for point cloud data and appearance defects, applied in image data processing, optical testing flaws/defects, measuring devices, etc., can solve problems such as inability to detect depth information, being easily affected by light sources, and difficult to locate and extract.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

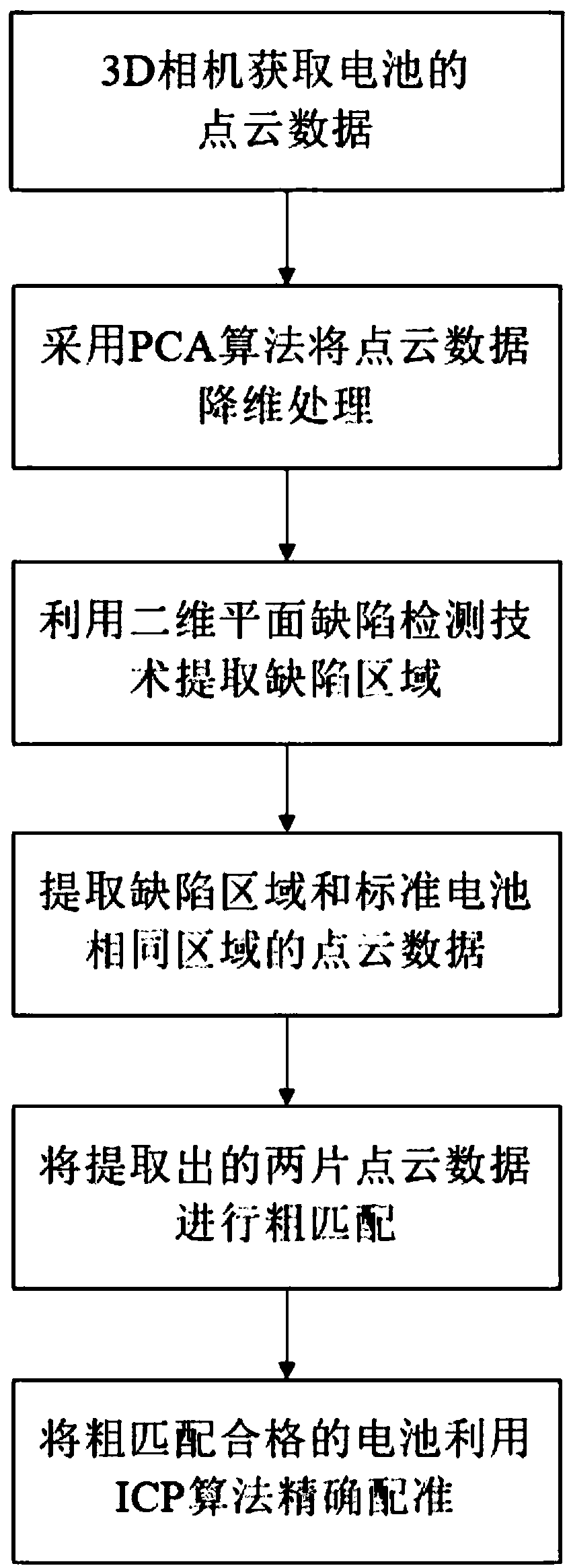

[0071] Such as figure 1 As shown, a battery appearance defect detection method based on dimensionality reduction and point cloud data matching provided in this embodiment includes the following steps:

[0072] Step 1: Use a 3D camera to obtain the 3D point cloud data of the battery to be tested;

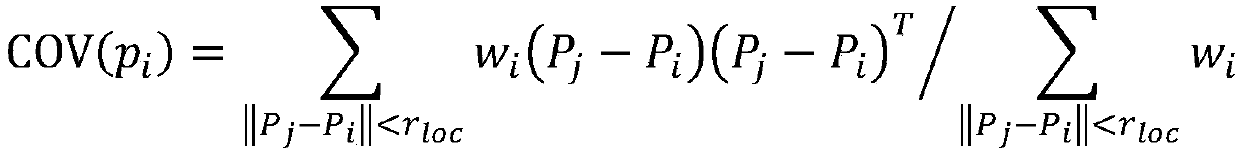

[0073] Step 2: Use the PCA dimensionality reduction algorithm to reduce the dimensionality of the point cloud data, including the following steps:

[0074] Step 2.1: Using the PCA dimensionality reduction algorithm, with m pieces of 3D data, the point cloud data is formed into a 3-row m-column matrix X by column;

[0075] Zero-meanize each row of matrix X, that is, subt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com