Method, apparatus and electronic device for detecting dirty areas in an image

A detection method and image technology, applied in the field of image processing, can solve the problems of poor consistency of detection results, manual detection defects, high misjudgment rate, etc., and achieve the effects of improving environmental adaptability, low image quality requirements, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

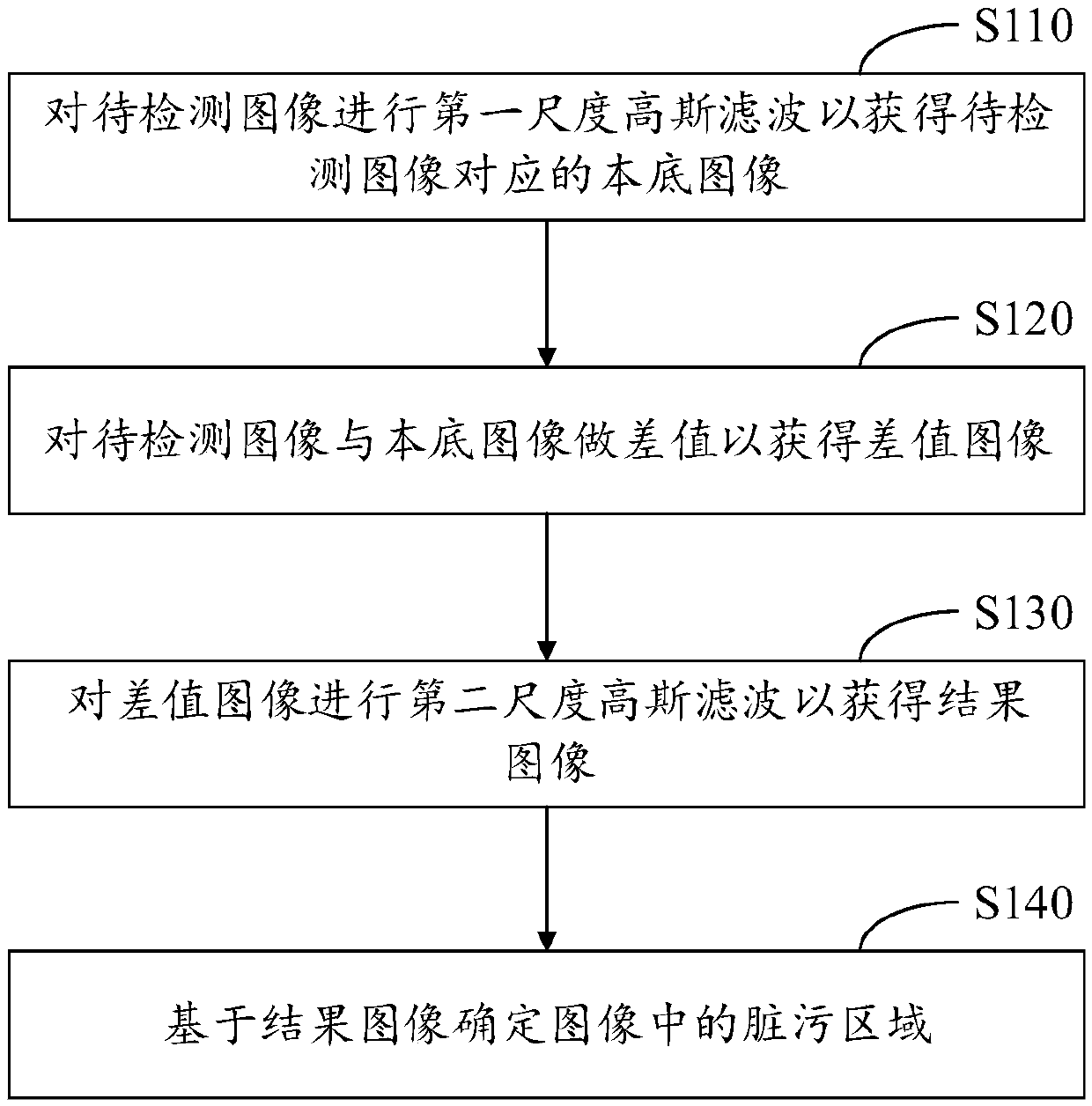

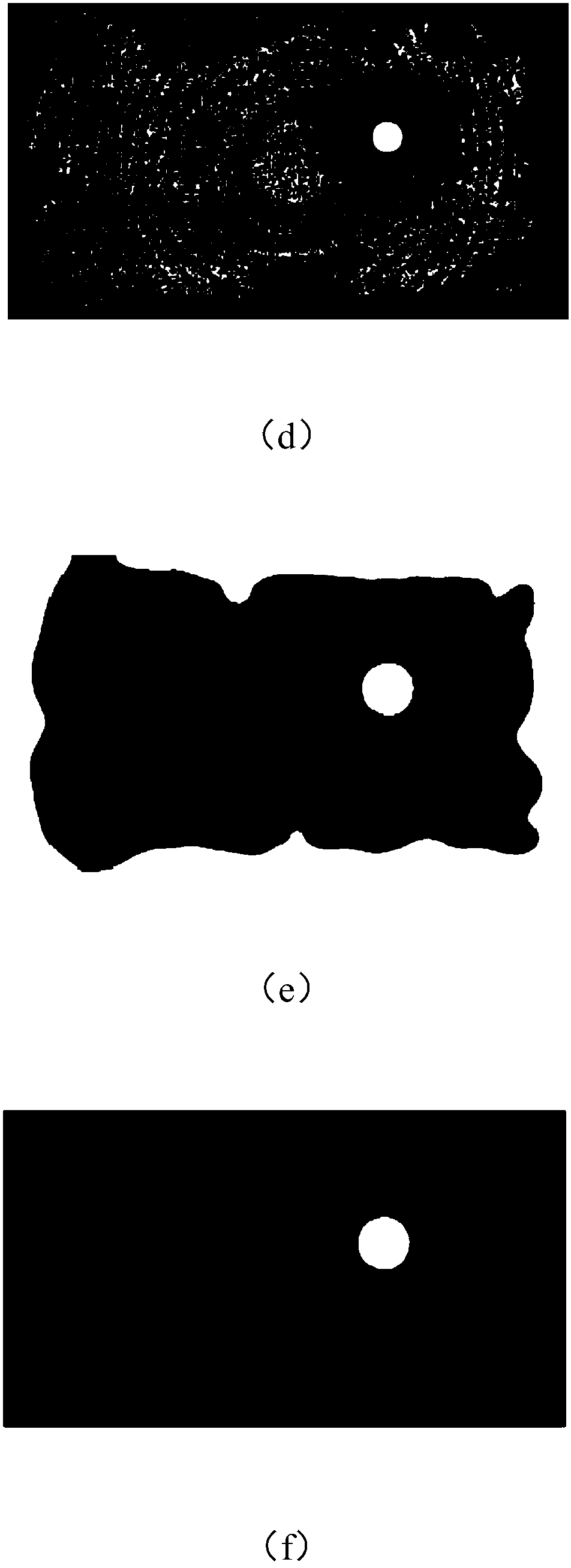

[0022] Hereinafter, exemplary embodiments according to the present application will be described in detail with reference to the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present application, rather than all the embodiments of the present application. It should be understood that the present application is not limited by the exemplary embodiments described here.

[0023] Application overview

[0024] As mentioned above, dirt detection is an important test item after the back-end assembly of the camera module is completed. The production workshop of the camera module is required to be a dust-free workshop, but due to the existence of bad blocks on the pixels on the sensor (that is, the area formed by a certain continuous area of bad pixels) and the dust particles and Other stains will cause the bright spots, dark spots, color spots and dark spots of the image to be dirty, which are all dirty inspections during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com