Indoor fire protection system

A fire-fighting and fire-fighting water pipe technology, applied in the direction of fire rescue, heat exchange materials, chemical instruments and methods, etc., can solve the problems of reduced timeliness, spread to a large extent, etc., to reduce damage, better fire extinguishing effect, reduce The effects of water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

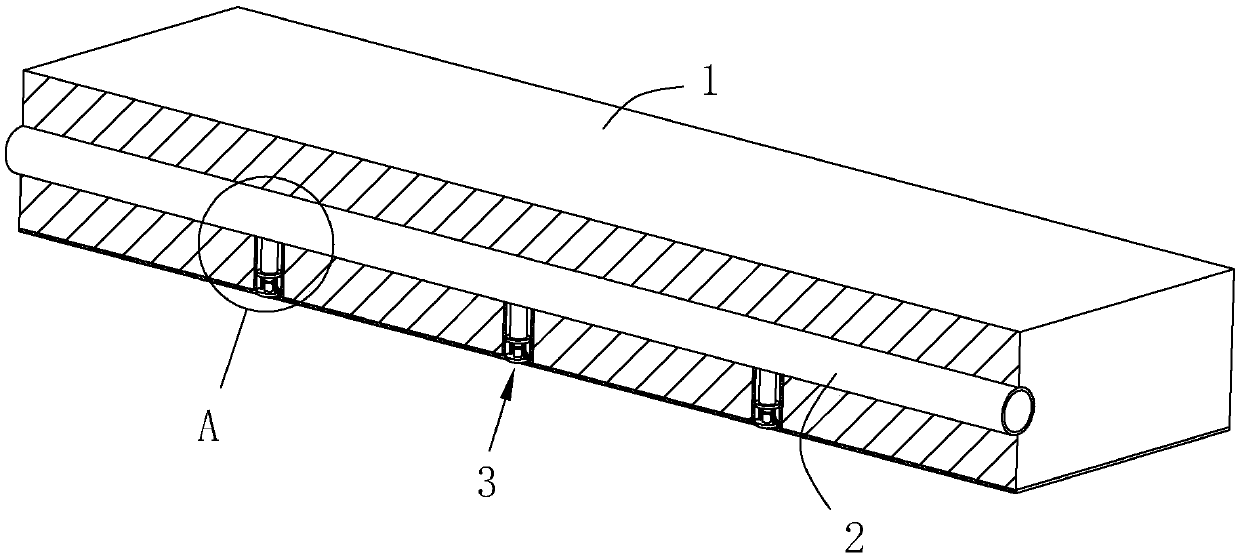

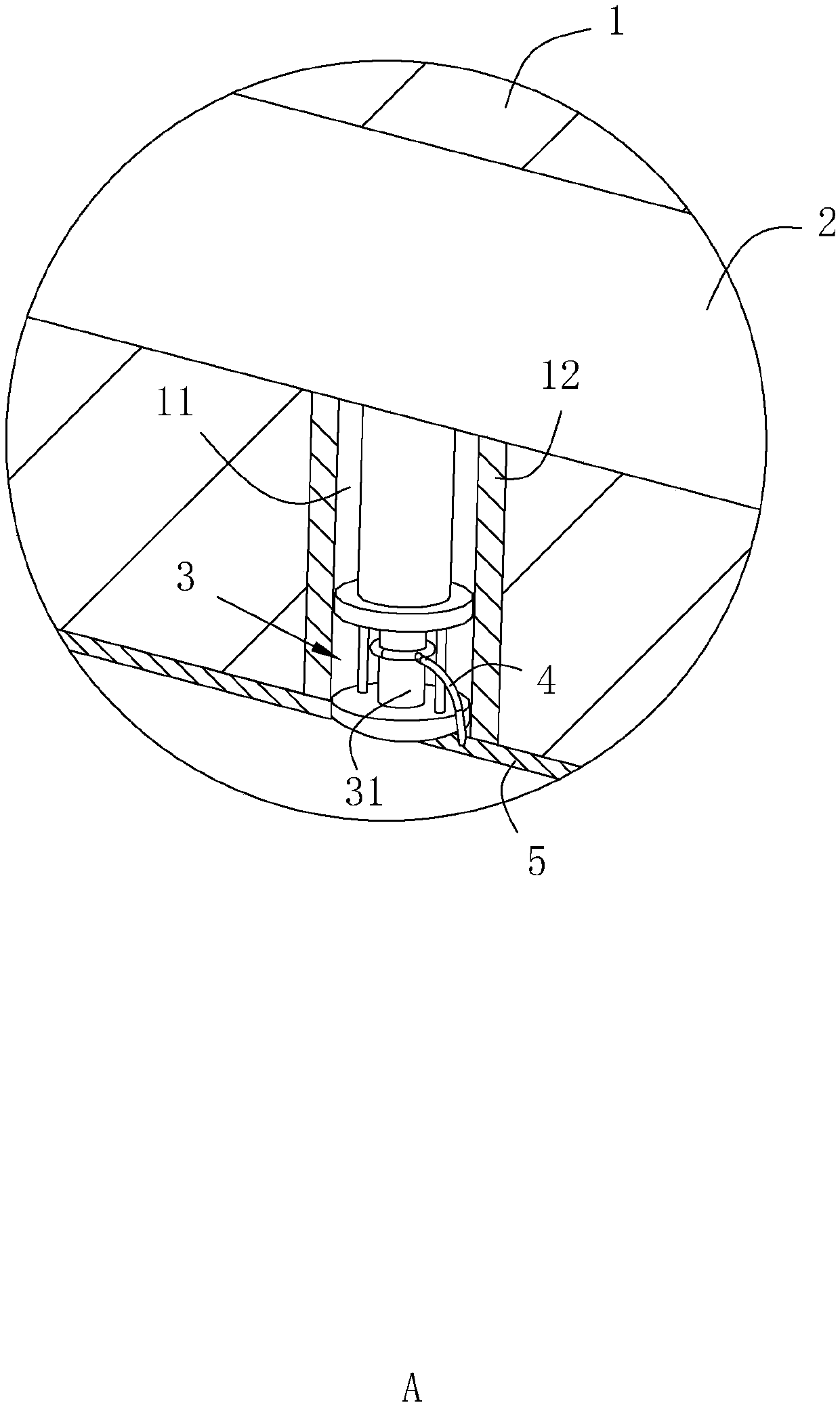

[0041] A kind of indoor fire prevention and fire prevention system, refer to figure 1 as well as figure 2 , the indoor building includes a top plate 1, the surface of the top plate 1 facing the room is recessed with a number of accommodation holes 11, the fire protection system includes a fire water pipe 2 buried in the top plate 1 and a number of fire sprinklers 3 connected with the fire water pipe 2, the fire sprinkler 3 is located in the accommodation hole In 11 , the fire prevention system further includes a heat-melt heat conduction layer 5 covering the surface of the top plate 1 facing the room to close the accommodation hole 11 .

[0042] The fire-fighting water pipe 2 is arranged horizontally, and the fire-fighting nozzle 3 extends downwards along the vertical direction. 5 abuts against the surface of the top plate 1.

[0043] Both the wall and the bottom of the receiving hole 11 are covered with a waterproof layer 12 , and in this embodiment, the waterproof layer 1...

Embodiment 2

[0068] The difference with embodiment 1 is:

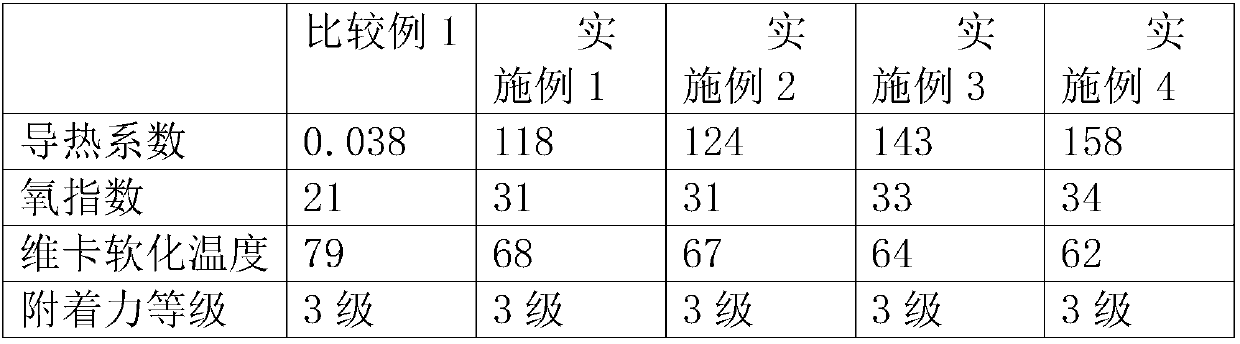

[0069] The hot-melt heat-conducting layer 5 includes the following components in parts by mass:

[0070] 100 parts of EVA resin; 22 parts of flame retardant; 28 parts of copper powder; 2.2 parts of cobalt salt; 18 parts of paraffin.

[0071] The VA content of EVA is 20%.

Embodiment 3

[0073] The difference with embodiment 1 is:

[0074] The hot-melt heat-conducting layer 5 includes the following components in parts by mass:

[0075] 100 parts of EVA resin; 25 parts of flame retardant; 30 parts of copper powder; 2.5 parts of cobalt salt; 17.5 parts of paraffin wax.

[0076] The VA content of EVA is 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com