Safe and reliable upper limb exercise device

An exercise device and an upper limb technology, applied in the field of physical exercise equipment, can solve the problems of rotator cuff injury, poor safety performance, poor applicability, etc., and achieve the effects of improving the quality of life, restoring the health of the upper limbs, and maintaining the mood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

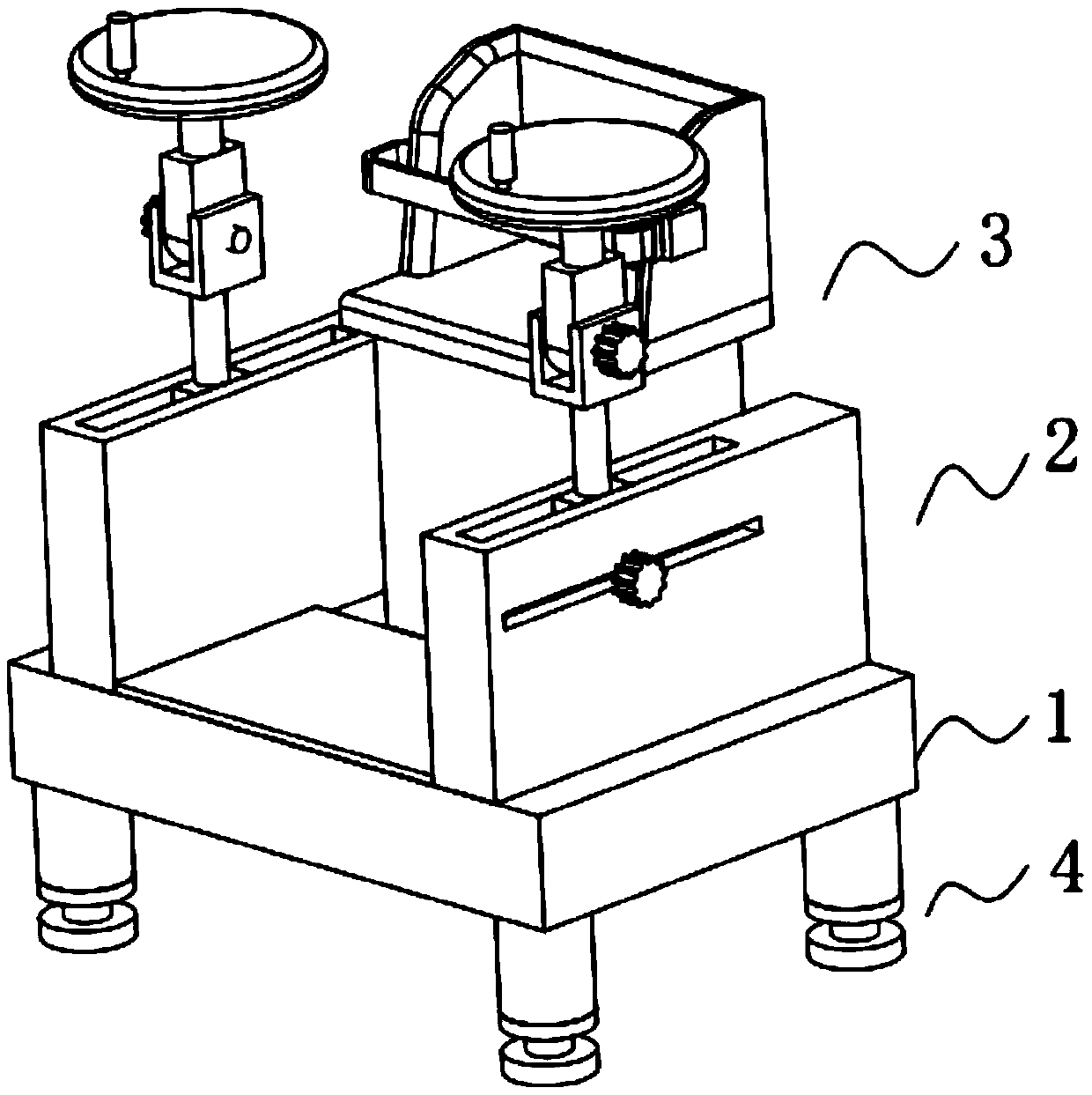

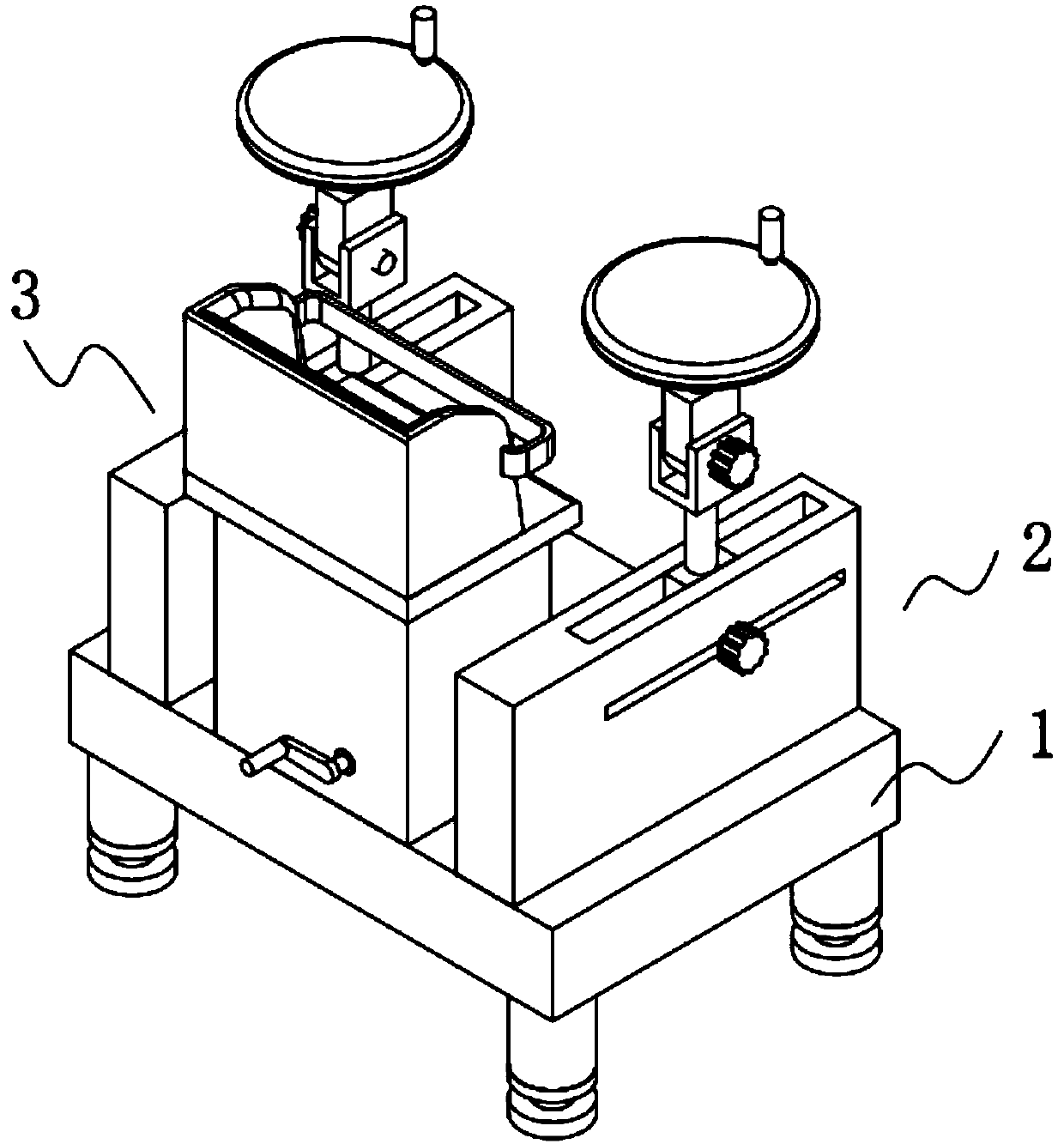

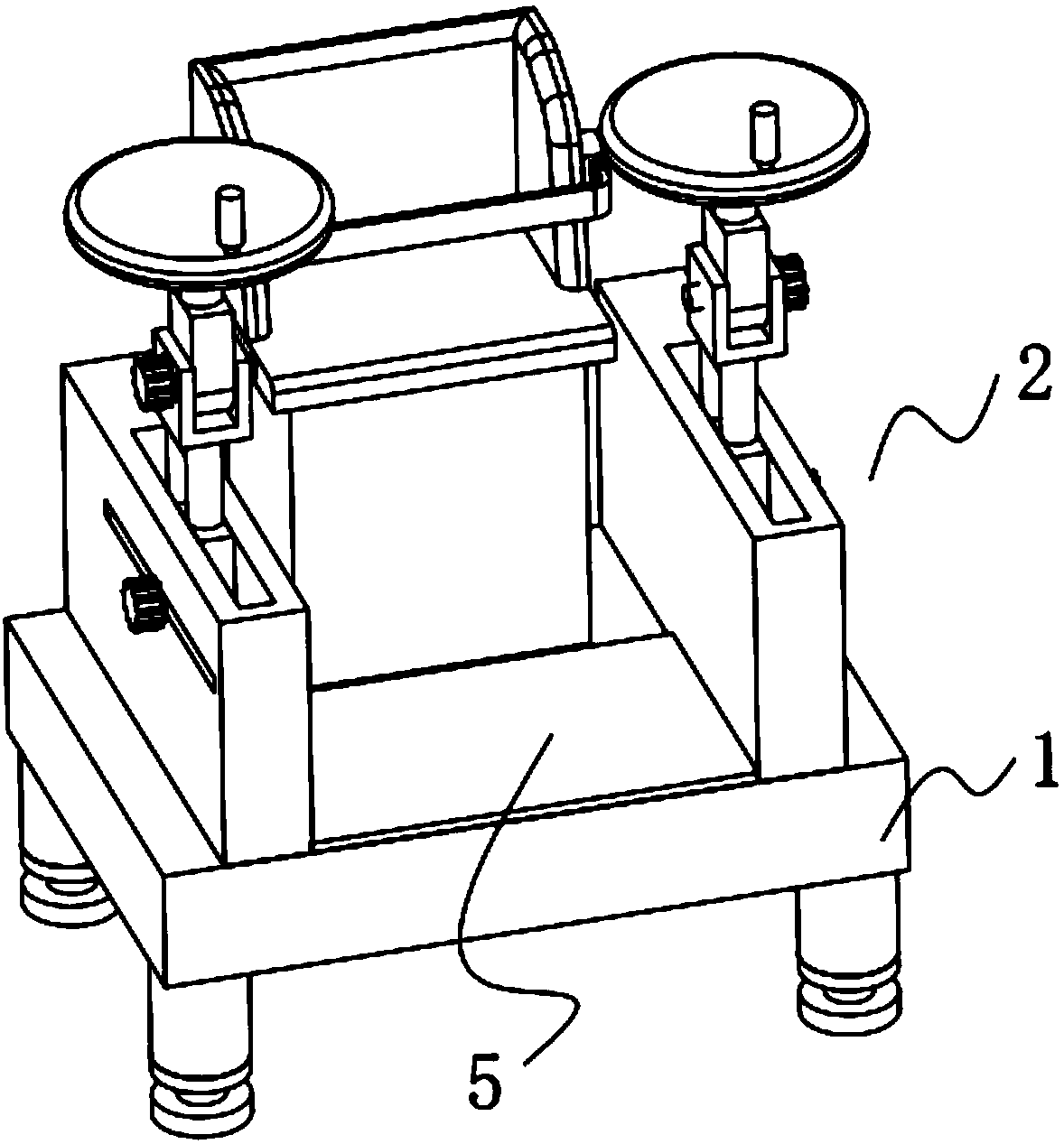

[0060] The following is attached Figure 1-17 The present invention is described in further detail.

[0061] A safe and reliable upper body exercising device, such as Figure 1-17 As shown, including a base plate 1, two groups of upper limb exercise units 2 are arranged symmetrically on both sides of the upper portion of the base plate 1, and the upper portion of the base plate 1 is provided with a support unit 3 between the two groups of upper limb exercise units 2;

[0062] The two groups of upper limb exercise units 2 all include a boss 6 fixedly installed on the top of the base plate 1, the upper surface of the boss 6 is provided with a chute 7, and the inside of the chute 7 is slidably installed with a slider 10. A vertical pole 11 is fixedly installed on the upper surface of the slider 10, and a U-shaped bracket 12 is fixedly installed on the upper end of the vertical pole 11, and the upper part of the U-shaped bracket 12 is fixedly installed with a support through an a...

Embodiment 2

[0074] The difference from Example 1 is that the handle 15 is also covered with a protective cover, and the protective cover is prepared by the following method:

[0075] Take the following raw materials and weigh them by weight: 30 parts of methyl vinyl phenyl silicone rubber, 15 parts of polyurethane, 10 parts of calcium carbonate powder, 15 parts of phenolic resin powder, 2 parts of p-phenylenediamine, 2 parts of triethanolamine 3 parts, 3 parts of paraffin oil, 3 parts of tricresyl phosphate;

[0076] S1. Put the weighed methyl vinyl phenyl silicone rubber and polyurethane into a pulverizer for pulverization. The speed of the pulverizer is set at 600r / min to prepare a pulverized mixed material, and pulverized the mixed material The particle diameter is 4mm;

[0077] S2. Put the pulverized mixed material prepared in step S1 into a banbury mixer for banburying. The temperature of the banbury mixer is set at 180° C., the speed is set at 700 r / min, and the banburying time is ...

Embodiment 3

[0083] The difference from Example 2 is the preparation of the protective cover, and its specific preparation method is as follows:

[0084] Take the following raw materials and weigh them by weight: 35 parts of methyl vinyl phenyl silicone rubber, 18 parts of polyurethane, 11 parts of calcium carbonate powder, 18 parts of phenolic resin powder, 3 parts of p-phenylenediamine, 3 parts of triethanolamine 4 parts, 4 parts of paraffin oil, 4 parts of tricresyl phosphate;

[0085] S1. Put the weighed methyl vinyl phenyl silicone rubber and polyurethane into a pulverizer for pulverization. The speed of the pulverizer is set at 700r / min to prepare a pulverized mixed material, and pulverized the mixed material The particle diameter is 7mm;

[0086] S2. Put the pulverized mixed material prepared in step S1 into a banbury mixer for banburying. The temperature of the banbury mixer is set at 190° C., the speed is set at 750 r / min, and the banburying time is 30 minutes to obtain banbury ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com