Multi-branch tube type crystallization tank

A technology of crystallization tank and tube type, which is applied in the field of multi-branch tube type crystallization tank, can solve the problems of unsatisfactory feeling and rough taste, and achieve the effect of facilitating equipment debugging and maintenance, improving product quality, and expanding the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

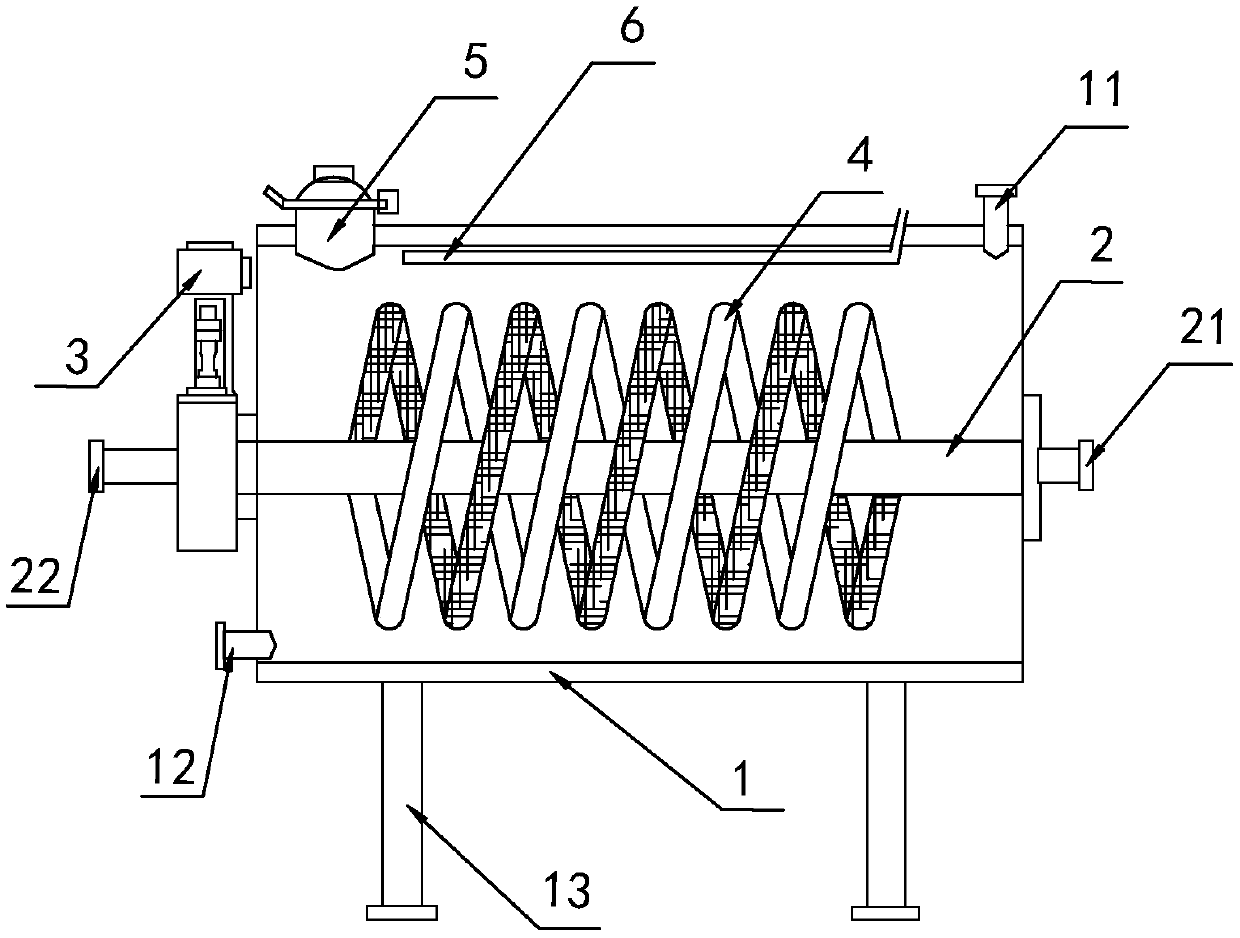

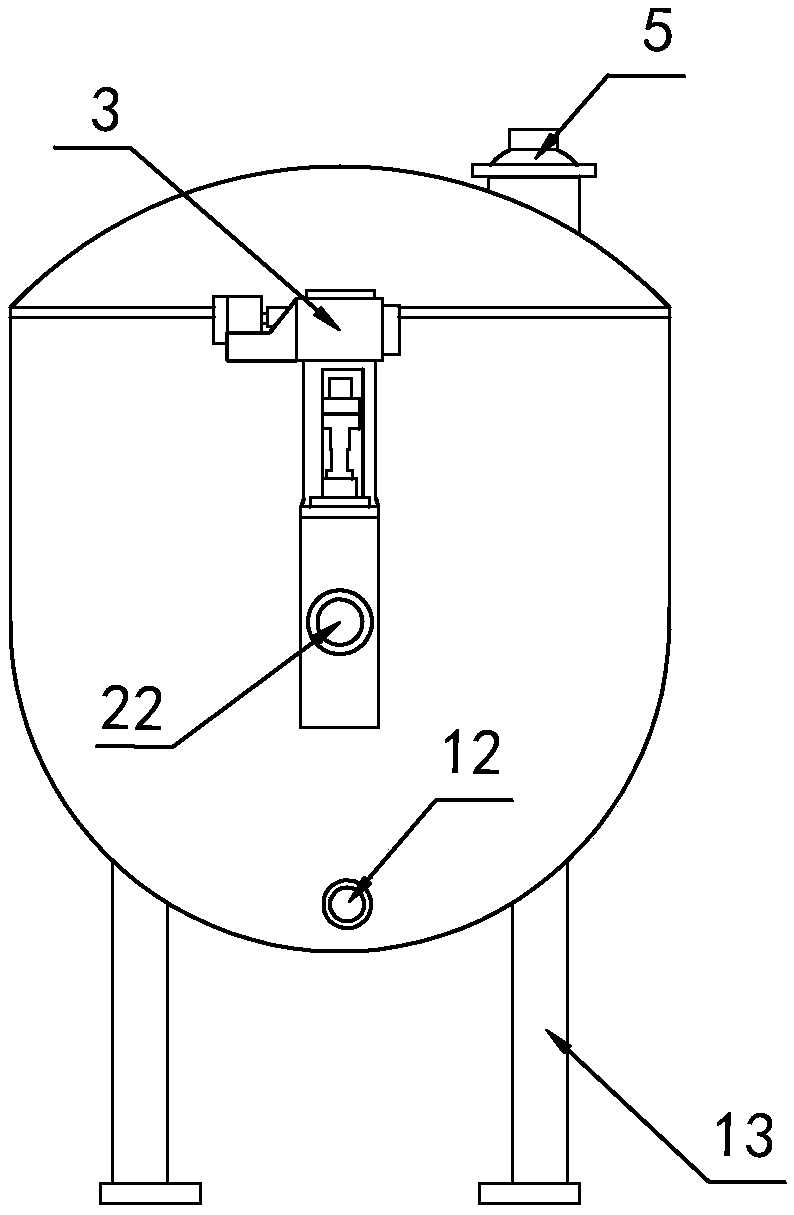

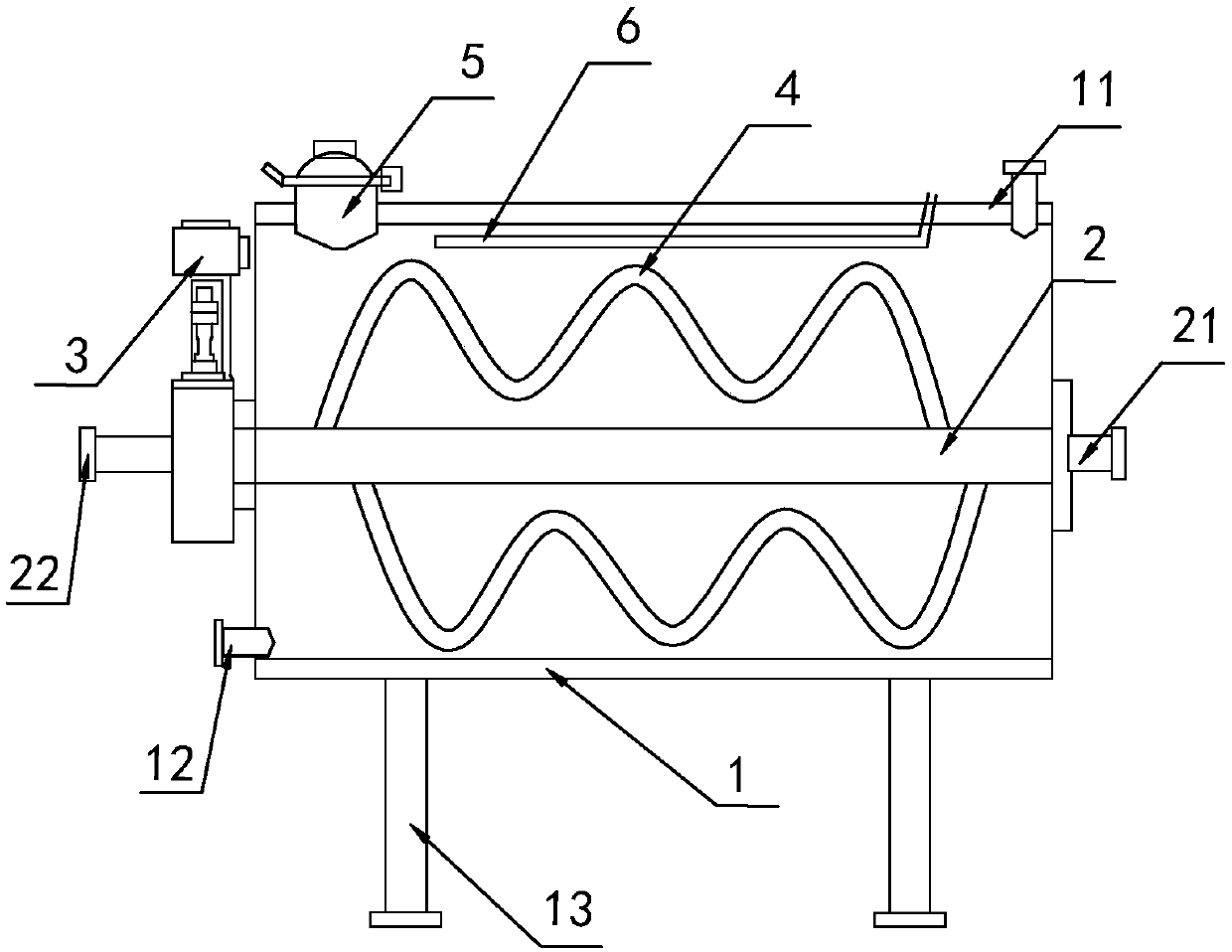

[0021] refer to Figure 1 ~ Figure 4 , the present invention is a manifold type crystallizing tank, comprising a tank body 1 , a rotating shaft 2 and a driving device 3 . The tank body 1 is generally cylindrical, but can also be designed into other shapes according to actual conditions. The rotating shaft 2 is generally an elongated hollow-walled tube, and at least a part of the rotating shaft 2 is located inside the tank body 1 . Generally, both ends of the rotating shaft 2 extend out of the tank body 1, and are provided with a water inlet 21 and a water outlet 22, which are used as the inlet and outlet of the ice water. The rotating shaft 2 is connected with the tank body 1 in rotation, that is, the rotating shaft 2 can rotate relative to the tank body 1, but at the same time, the leakage problem should be avoided. Several branch pipes 4 are fixed on the rotating shaft 2 , and the branch pipes 4 are located inside the tank body 1 . Generally, both ends of the branch pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com