The z-direction reference plane detection and setting method of vertical milling machine

A datum plane, vertical milling machine technology, used in measuring/indicating equipment, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of slow speed to the initial origin, poor reliability, etc., to reduce datum errors and ensure stability The effect of improving the accuracy of alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

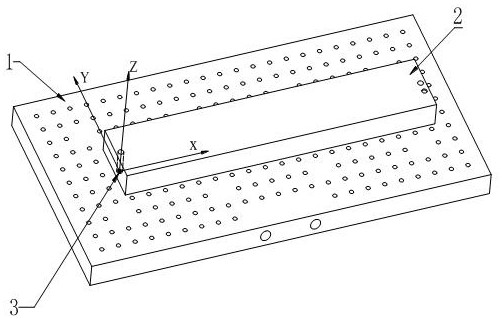

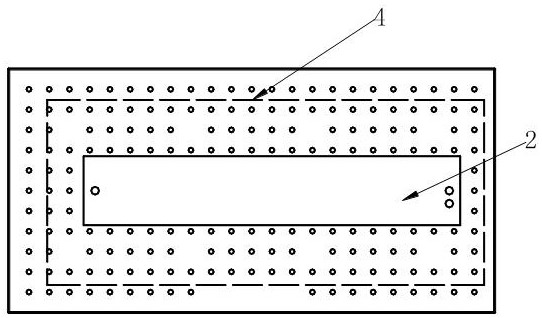

[0050] The present invention is realized through the following technical solutions, as Figure 1-Figure 6 As shown, the Z-direction datum plane detection and setting method of the vertical milling machine uses the probe to align the datum processing plane and calibrate. Before measurement, determine the contour of the plane according to the size and position of the blank 2 of the part on the tooling, and take the contour of the positioning plane as the boundary , according to the position of the positioning surface of the part, select a number of sampling points as the sampling position, and within the tolerance range, take the average value of the Z values of the sampling points as the position of the Z-direction reference plane.

[0051] Further, in order to better realize the present invention, specifically include the following steps:

[0052] Step B: probe calibration;

[0053] Step C: According to the placement position of the part blank 2, determine the detection are...

Embodiment 2

[0076] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 , figure 2 As shown, a Z-direction reference plane detection and setting method suitable for vertical milling machines is characterized in that it adopts an automatic measurement method using probe detection and a standard measurement program for nested CNC systems, and the probe used has position detection perception function, and can feed back the measurement results to the control system; the automatic measurement method is composed of a tool cleaning method, a probe length calibration method, a probe diameter calibration method, and a Z-direction plane probe measurement method;

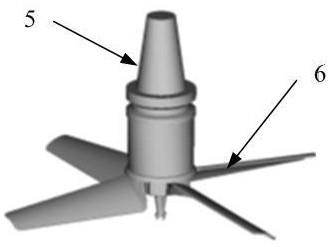

[0077] The tool cleaning method described above uses a special fan for cleaning. The structure of the fan is similar to that of the cutting tool. The working part is a fan blade, which is connected to the main shaft of the machine tool through the tool handle. When cleaning, the main shaft rotates ...

Embodiment 3

[0087] The preferred embodiment of the Z-direction reference plane detection and setting method of the vertical milling machine in the present invention is as figure 1 Shown is a part to be processed, using positioning tool 1 for clamping and positioning, the positioning method of the part blank 2 is process hole and reference plane positioning, the origin 3 of the machining coordinate system is located at the left process hole, and the Z-direction reference plane is on the positioning tool 1 surface.

[0088] Use the probe to align the reference processing plane. Firstly, it is necessary to clean the upper surface of the positioning tool 1, draw a line according to the size of the part blank 2 to determine the contour 4 of the cleaning area, and remove the part blank 2.

[0089] Use clean fan structures such as image 3 As shown, the fan is composed of a fan body 5 and fan blades 6. The fan is connected to the main shaft of the machine tool. The rotation of the main shaft dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com