Heat transfer printing antistatic paint special for plastics and preparation method

An antistatic plastic and thermal transfer printing technology, applied in conductive coatings, polyester coatings, coatings, etc., can solve the problems of roughening, spots, patterns, paper scraps, and dust absorption on full-page parts, and achieve improved anti-static Static performance, antistatic effect, long-lasting effect, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

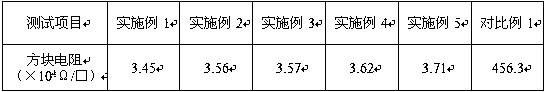

Examples

Embodiment 1

[0031] a, adding graphene oxide into deionized water, uniformly dispersed to obtain a graphene oxide dispersion; wherein, 20 parts by weight of graphene oxide and 80 parts by weight of deionized water;

[0032] b. Add hydrogen bromide solution and oxalic acid with a mass concentration of 55% to the graphene oxide dispersion prepared in step a, mix and stir for 45 minutes, carry out carboxylation modification to graphene oxide, filter and dry after completion , to obtain carboxylated graphene oxide; wherein, 68 parts by weight of graphene oxide dispersion, 12 parts by weight of hydrogen bromide solution, 20 parts by weight of oxalic acid;

[0033] c. Dissolve the carboxyl-terminated PET resin in an organic solvent, then add the carboxylated graphene oxide prepared in step b, ultrasonically disperse for 15 minutes, further add a reactive crosslinking agent, stir and react for 20 minutes, then add a reducing agent and stir 60min, graphene oxide is reduced, and antistatic plastic ...

Embodiment 2

[0035] a, adding graphene oxide into deionized water, uniformly dispersed to obtain a graphene oxide dispersion; wherein, 10 parts by weight of graphene oxide and 90 parts by weight of deionized water;

[0036] b. Add hydrogen bromide solution and oxalic acid with a mass concentration of 50% to the graphene oxide dispersion prepared in step a, mix and stir for 30 minutes, carry out carboxylation modification to graphene oxide, filter and dry after completion , to obtain carboxylated graphene oxide; wherein, 72 parts by weight of graphene oxide dispersion, 10 parts by weight of hydrogen bromide solution, 18 parts by weight of oxalic acid;

[0037] c. Dissolve the carboxyl-terminated PET resin in an organic solvent, then add the carboxylated graphene oxide prepared in step b, ultrasonically disperse for 15 minutes, further add a reactive crosslinking agent, stir and react for 20 minutes, then add a reducing agent and stir 45min, the graphene oxide was reduced to prepare the spec...

Embodiment 3

[0039]a, adding graphene oxide into deionized water, uniformly dispersed to obtain a graphene oxide dispersion; wherein, 30 parts by weight of graphene oxide and 70 parts by weight of deionized water;

[0040] b. Add hydrogen bromide solution and oxalic acid with a mass concentration of 60% to the graphene oxide dispersion prepared in step a, mix and stir for 30 minutes, carry out carboxylation modification to graphene oxide, filter and dry after completion , to obtain carboxylated graphene oxide; wherein, 63 parts by weight of graphene oxide dispersion, 15 parts by weight of hydrogen bromide solution, 22 parts by weight of oxalic acid;

[0041] c. Dissolve the carboxyl-terminated PET resin in an organic solvent, then add the carboxylated graphene oxide prepared in step b, ultrasonically disperse for 20 minutes, further add a reactive crosslinking agent, stir and react for 15 minutes, then add a reducing agent and stir 45min, the graphene oxide was reduced to prepare the speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com