Brewing technology of fragrance enhancement type wine

A wine and craft technology, applied in the field of food processing, can solve the problem of single aroma structure, etc., and achieve the effect of single aroma, refreshing and smooth taste, and fine pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The brewing process of flavor-enhancing wine provided by this embodiment includes the following steps:

[0028] (1) Preparation of the base wine: take the wine made from the winter fruits of the grape variety "Guipu 6" as the base wine for use; the base wine is brewed by the following method: prepare the grape mash from the winter fruits of the grape variety "Guipu 6" The grape juice is separated from the grape mash and fermented to obtain the raisin wine. The raisin wine is first treated with a pulsed electric field with a frequency of 8 Hz and an electric field strength of 20 kV / cm for 400 μs, and then sterilized by ultraviolet irradiation with a wavelength of 180 nm for 2 minutes. Supercritical CO after sterilization 2 Fluid extraction, extraction pressure is 17MPa, extraction temperature is 33℃, CO 2 The flow rate is 22L / h, and the extraction time is 2h. After the extraction is completed, the pressure is quickly reduced to 4MPa, the temperature is increased to 48°C, the...

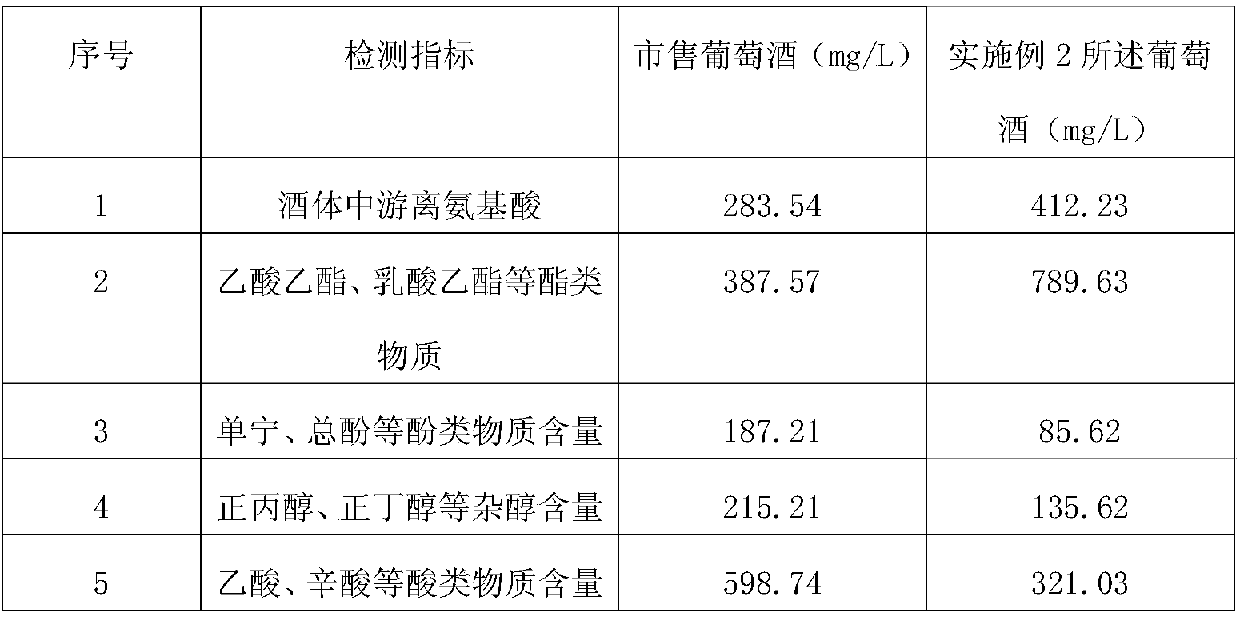

Embodiment 2

[0034] The brewing process of flavor-enhancing wine provided in this embodiment includes the following steps:

[0035] (1) Preparation of the base wine: take the wine made from the winter fruit of the grape variety "Guipu 6" as the base wine for use; the base wine is brewed by the following method: prepare the grape mash from the winter fruit of the grape variety "Guipu 6" The grape juice is separated from the grape mash and fermented to obtain raisin wine. The raisin wine is first treated with a pulsed electric field with a frequency of 10 Hz and an electric field intensity of 25 kV / cm for 420 μs, and then sterilized by ultraviolet irradiation with a wavelength of 180 nm for 3 minutes. Supercritical CO after sterilization 2 Fluid extraction, extraction pressure is 18MPa, extraction temperature is 34℃, CO 2 The flow rate is 22L / h, and the extraction time is 2.5h. After the extraction is completed, the pressure is quickly reduced to 4MPa, the temperature is increased to 50°C, the e...

Embodiment 3

[0041] The brewing process of flavor-enhancing wine provided in this embodiment includes the following steps:

[0042] (1) Preparation of the base wine: take the wine made from the winter fruit of the grape variety "Guipu 6" as the base wine for use; the base wine is brewed by the following method: prepare the grape mash from the winter fruit of the grape variety "Guipu 6" The grape juice is separated from the grape mash and fermented to obtain raisin wine. The raisin wine is first treated with a pulsed electric field with a frequency of 12 Hz and an electric field strength of 30 kV / cm for 450 μs, and then sterilized by ultraviolet irradiation with a wavelength of 180 nm for 4 minutes. Supercritical CO after sterilization 2 Fluid extraction, extraction pressure is 19MPa, extraction temperature is 36℃, CO 2 The flow rate is 22L / h, and the extraction time is 3h. After the extraction is completed, the pressure is quickly reduced to 5MPa, the temperature is increased to 52°C, the extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com