Metal composite material containing anti-corrosion coating, degradable magnesium alloy bone screw and application

A metal composite material and anti-corrosion coating technology, which is applied in the field of medical devices, can solve problems affecting bone healing and inflammation, and achieve the effects of improving anti-degradation performance, improving affinity, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Using Mg-2Zn-0.5Y-1Nd-0.5Zr alloy as the metal raw material, the multi-axis CNC machining center is used to process bone screws into bone screws, and then the following pretreatments are performed: 0.1M sodium hydroxide solution is ultrasonically cleaned and placed in sequence Cleaning in pure water and absolute ethanol, drying at 45°C, conventional electropolishing in phosphoric acid-ethanol solution;

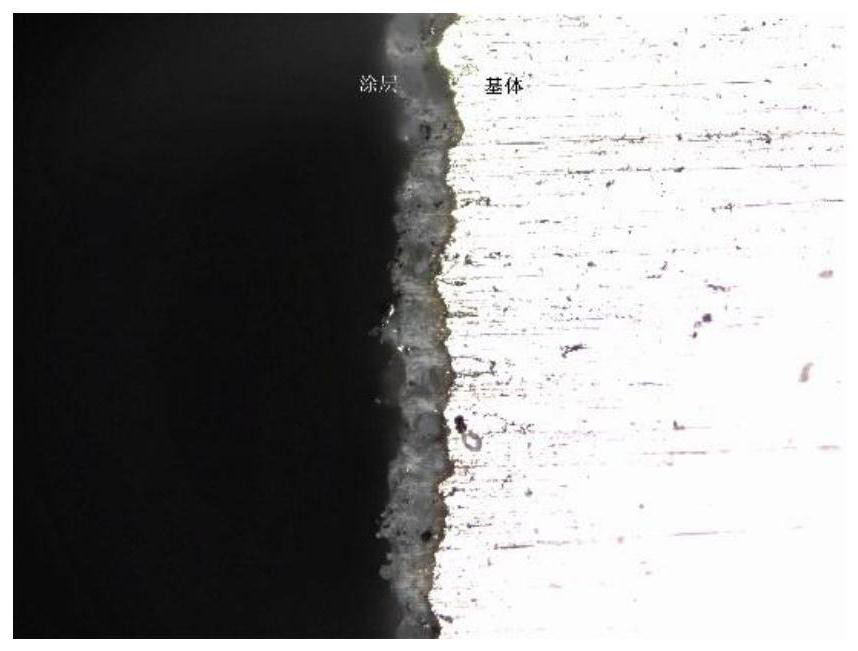

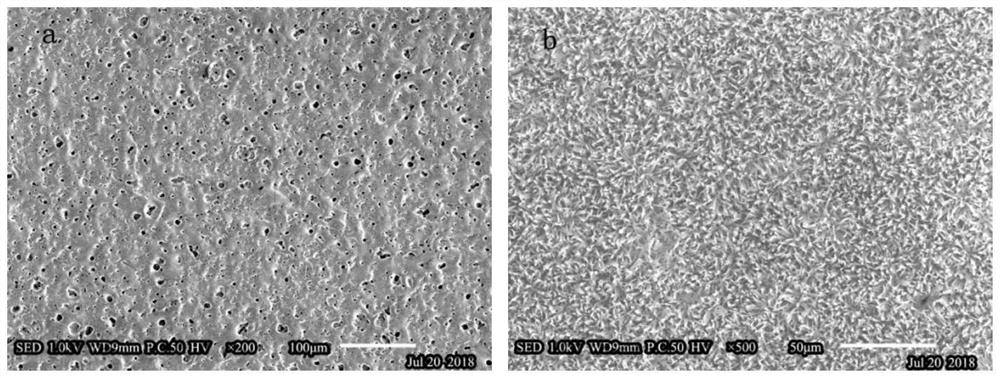

[0059] (2) Place the metal raw material pretreated in step (1) in a micro-arc oxidation electrolyte for micro-arc oxidation treatment, wherein the micro-arc oxidation electrolyte is a silicate system and contains the following components at a final concentration: 30g / L sodium silicate, 2g / L sodium hydroxide and 4g / L glycerin, the specific conditions of micro-arc oxidation treatment are: adopt the constant voltage mode of bidirectional pulse high voltage power supply, the electrical parameters are: forward frequency 750Hz, duty cycle 25 %, the forward voltage is 310...

Embodiment 2

[0065] (1) Using Mg-2Zn-0.5Y-1Nd-0.5Zr alloy as the metal raw material, the multi-axis CNC machining center is used to process bone screws into bone screws, and then the following pretreatments are performed: 0.1M sodium hydroxide solution is ultrasonically cleaned and placed in sequence Cleaning in pure water and absolute ethanol, drying at 45°C, conventional electropolishing in phosphoric acid-ethanol solution;

[0066] (2) Place the metal raw material pretreated in step (1) in a micro-arc oxidation electrolyte for micro-arc oxidation treatment, wherein the micro-arc oxidation electrolyte is a silicate system and contains the following components at a final concentration: 40g / L sodium silicate, 6g / L sodium hydroxide and 12g / L glycerin, the specific conditions of micro-arc oxidation treatment are: adopt the constant voltage mode of bidirectional pulse high voltage power supply, the electrical parameters are: forward frequency 750Hz, duty cycle 25 %, the forward voltage is 31...

Embodiment 3

[0073] (1) Using Mg-2Zn-0.5Y-1Nd-0.5Zr alloy as the metal raw material, the multi-axis CNC machining center is used to process bone screws into bone screws, and then the following pretreatments are performed: 0.1M sodium hydroxide solution is ultrasonically cleaned and placed in sequence Cleaning in pure water and absolute ethanol, drying at 45°C, conventional electropolishing in phosphoric acid-ethanol solution;

[0074] (2) Place the metal raw material pretreated in step (1) in a micro-arc oxidation electrolyte for micro-arc oxidation treatment, wherein the micro-arc oxidation electrolyte is a silicate system and contains the following components at a final concentration: 35g / L sodium silicate, 4g / L sodium hydroxide and 8g / L glycerin, the specific conditions of micro-arc oxidation treatment are: adopt the constant voltage mode of bidirectional pulse high voltage power supply, the electrical parameters are: forward frequency 750Hz, duty cycle 25 %, the forward voltage is 310...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap