Construction method of bored pile

A technology of bored cast-in-place piles and construction methods, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of low efficiency of hole slag extraction, reduce the effective section size, facilitate assembly, and meet the requirements of rapid slag extraction. and slag removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Reinforcement cage hanger design and construction technical requirements, prefabricated carrier production and installation technical requirements, slag removal device production and construction technical requirements, concrete mix ratio design and pouring construction technical requirements, etc., will not be described in detail in this embodiment. Embodiments of the invention relating to the method are illustrated.

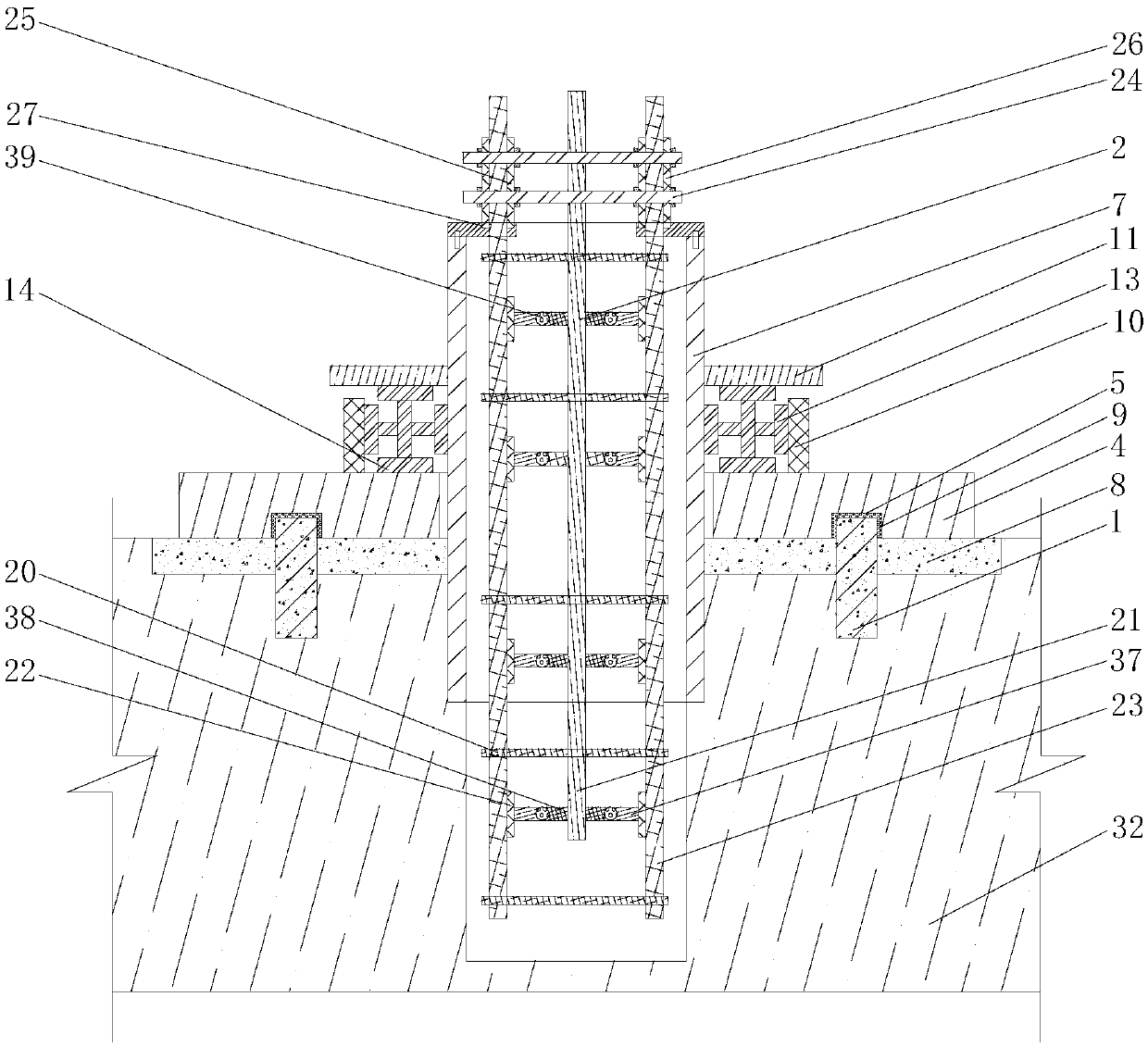

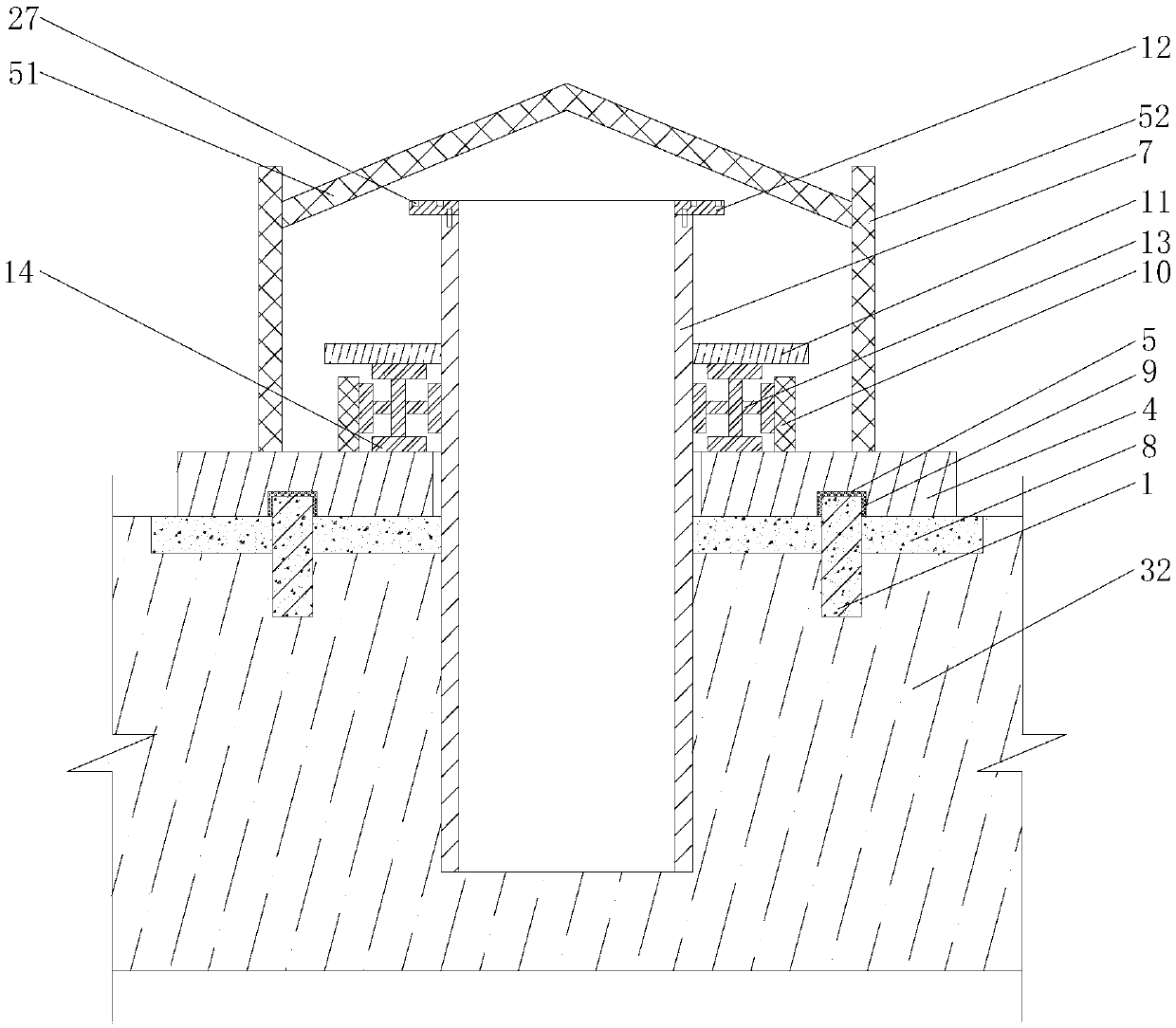

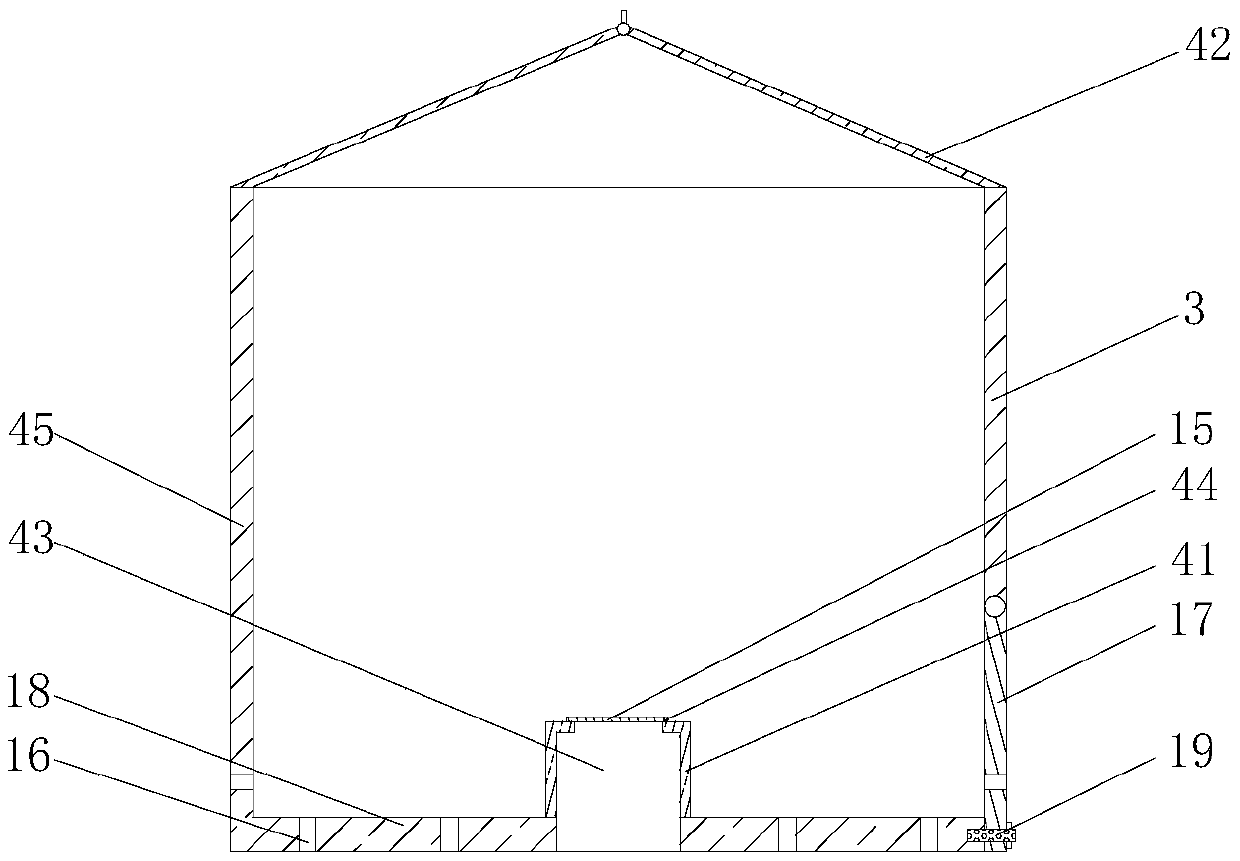

[0035] figure 1 It is a schematic diagram of the hoisting construction structure of cast-in-situ pile reinforcement cage of the present invention, figure 2 It is a schematic diagram of the structure after the fixed casing of the present invention is laid out, image 3 It is a schematic cross-sectional view of the structure of the slag remover of the present invention, Figure 4 It is a schematic cross-sectional view of the inner ring plate and the outer ring plate of the steel cage hoisting frame of the present invention, Figure 5 It is a schematic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com