Construction method for subsea tunnel

A technology for subsea tunnels and tunnels, applied in construction, water conservancy projects, artificial islands, etc., can solve problems such as low efficiency and construction difficulties, and achieve the effect of reducing construction difficulty, improving construction work efficiency, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be further described below in conjunction with the drawings:

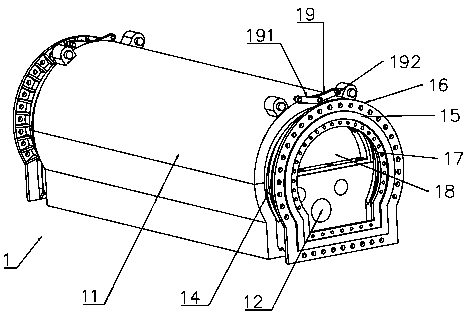

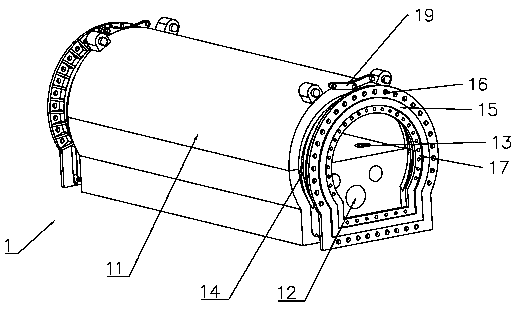

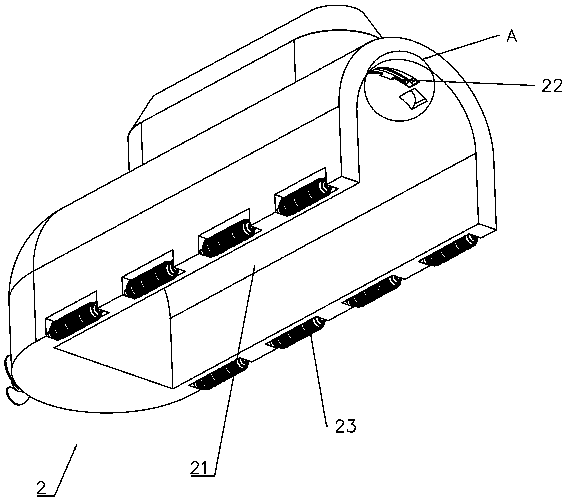

[0032] Such as figure 1 and figure 2 As shown, a tunnel prefab 1 includes a tunnel body 11 having an arched structure. A plurality of horizontal drainage pipes 12 and vertical connecting piles 13 are preset on the base of the tunnel body 11. The tunnel body 11 Floating rings 14 are provided at the front and rear ends of the floating ring 14, a sealing ring 15 is formed at the end of the floating ring 14, the outer ring of the sealing ring 15 is provided with an outer connecting ring 16, and the inner ring of the sealing ring 15 is provided with an inner connecting ring 17. Both the outer connecting ring 16 and the inner connecting ring 17 are formed with a number of evenly distributed bolt holes. The two ends of the tunnel body 11 are also provided with a sealing wall 18 for sealing the tunnel body 11, and the sealing wall 18 is connected to the tunnel The body 11 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap