Steel structure building cast-in-place concrete hollow floor system self-bearing hanging bracket formwork erecting technology

A technology for an empty floor and concrete, which is applied to the on-site preparation of building components, construction, building construction, etc., can solve problems such as hindering the immediate advancement of construction projects, heavy erection and demolition work, and long demolding cycle, etc., to eliminate The effect of heavy manual labor, reduction of labor costs for mold support, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

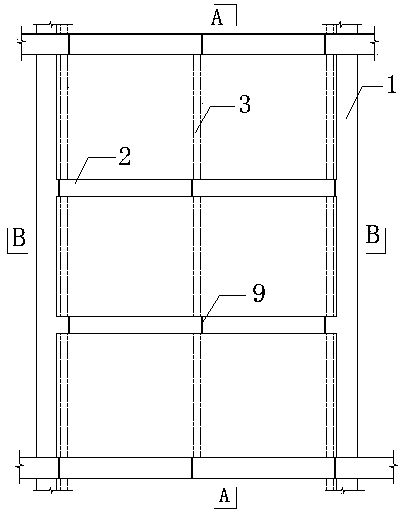

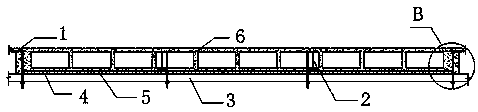

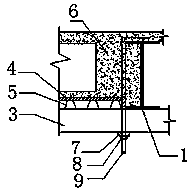

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the construction process of the present invention is as follows: welding supporting form force suspension rod→installing supporting form steel beam base→fixing supporting form steel beam→laying corrugated steel plate→full paving wood template→binding steel bar→pouring concrete.

[0033] Construction requirements of the invention:

[0034] 1. Formwork force suspension rod 9 adopts M14 screw rod, the length is determined according to the thickness of the floor, generally 550-600 long, the top is bent at 90°, and the end hook length is not less than 100, and it is firmly welded and fixed on the building floor. The upper part of the steel beam.

[0035] 2. Forced support top support

[0036] ①It is used for individual unable to set the position of the force supporting rod.

[0037] ②It is used to strengthen and support the bottom of H100 steel beam in the middle of the room, generally no less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com