Concrete filled steel tube arc frame for supporting architecture corridor

A technology of concrete filled steel tube and corridor, applied in the field of arch frame, can solve the problems of the overall strength and service life of the arch frame, lack of side support structure, inconvenient transportation and handling, etc., to extend service life and use safety, reduce installation The effect of labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

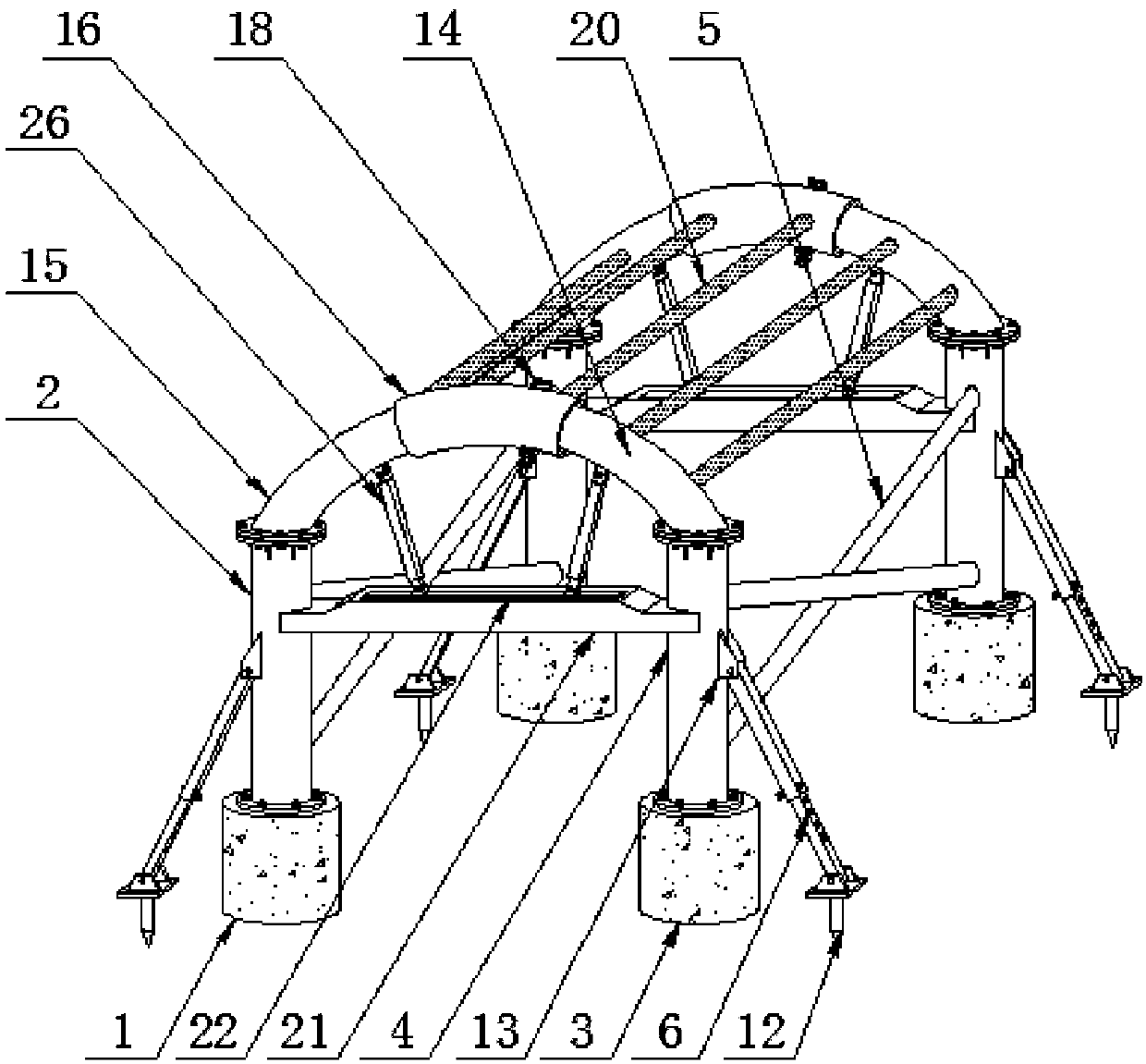

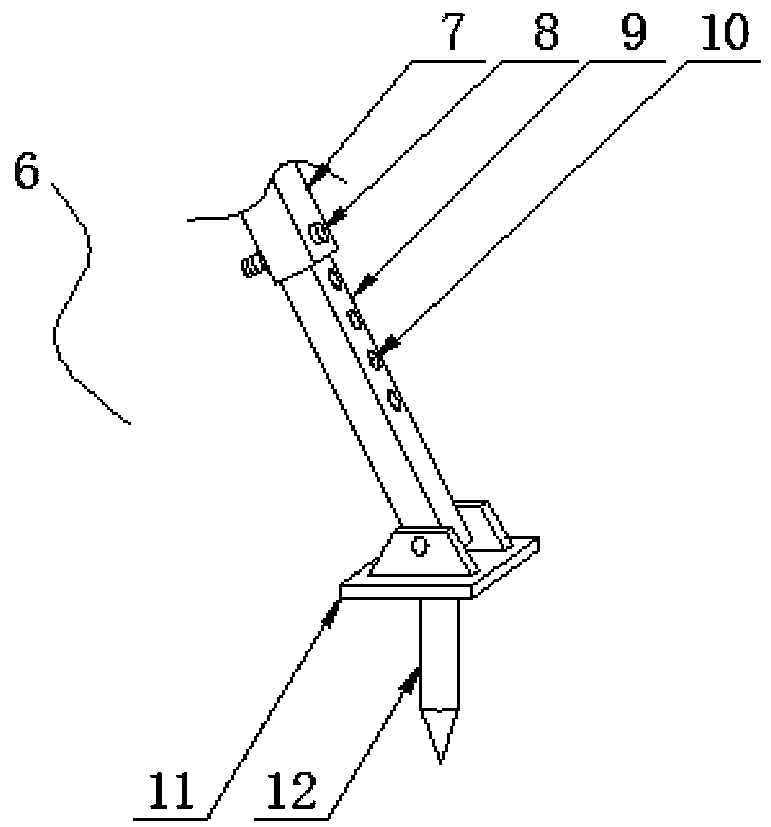

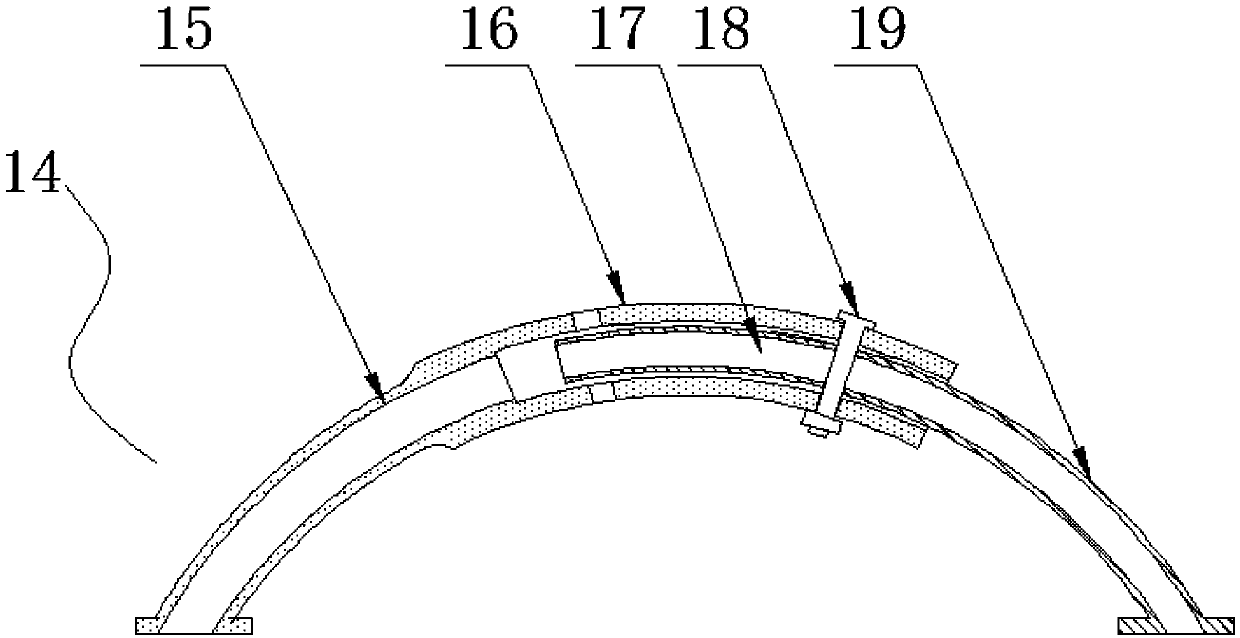

[0029] see Figure 1~5 , in an embodiment of the present invention, a concrete-filled steel tube arch frame for building corridor support includes a transverse frame assembly, a longitudinal bar 20 and an auxiliary support assembly, wherein the transverse frame assembly is within the width of the building corridor direction, and arranged perpendicularly to the longitudinal extension direction of the building corridor, two adjacent transverse frame components are connected by a plurality of longitudinal rods 20 arranged in parallel, and the longitudinal rods are arranged along the length of the building corridor. Extending in the direction, each side of the transverse frame assembly is provided with an auxiliary support assembly extending into and anchored on the ground; it is characterized in that,

[0030] The horizontal frame assembly is an arch structure, and the horizontal frame assembly is a steel pipe concrete structure, and the horizontal frame assembly includes a verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com