Mounting structure and mounting method of deep well pump pipe in civil air defense room of comprehensive building

A technology of installation structure and installation method, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, which can solve the problem of cracking of the welding seam connecting the flange and the pump pipe, the small diameter of the wellhead of the deep well pump, and the difficulty in solving the problems. Guarantee water supply performance and other issues to reduce pump maintenance, enhance stability, and avoid swing collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

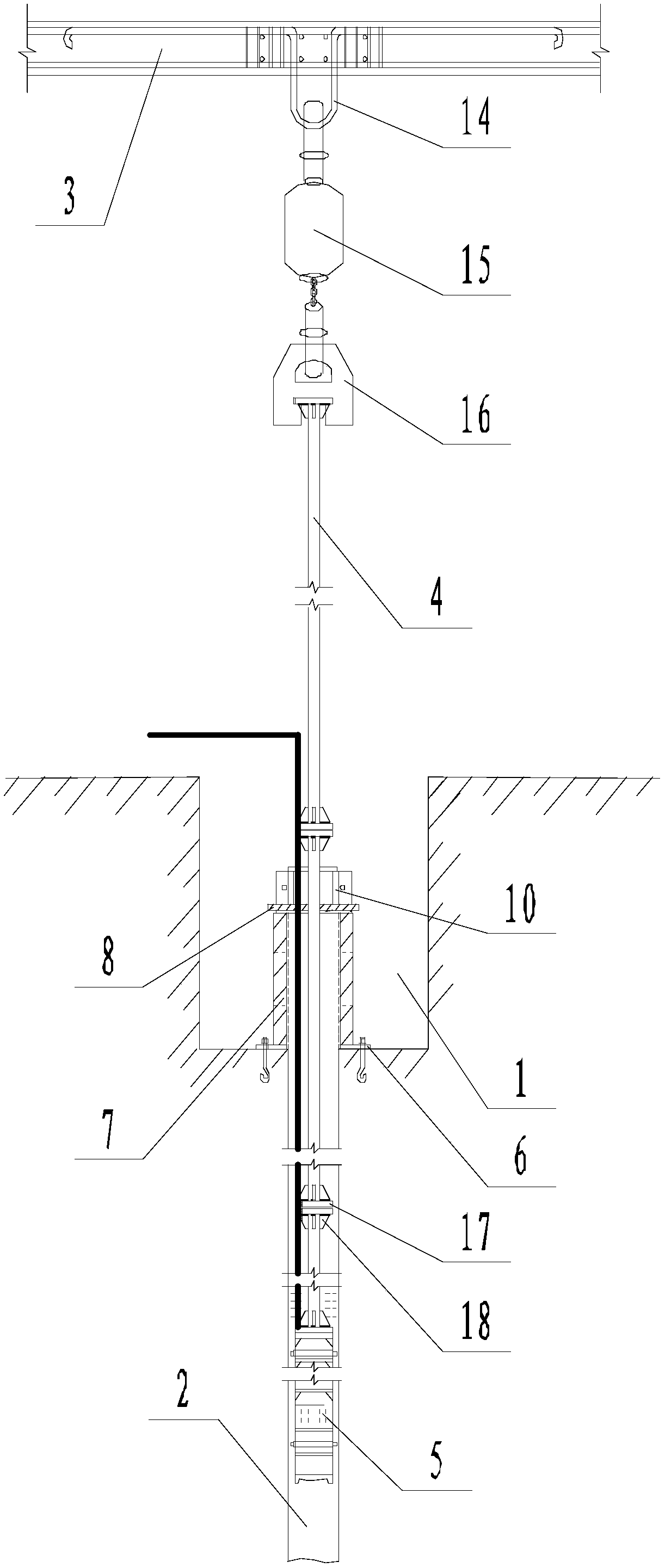

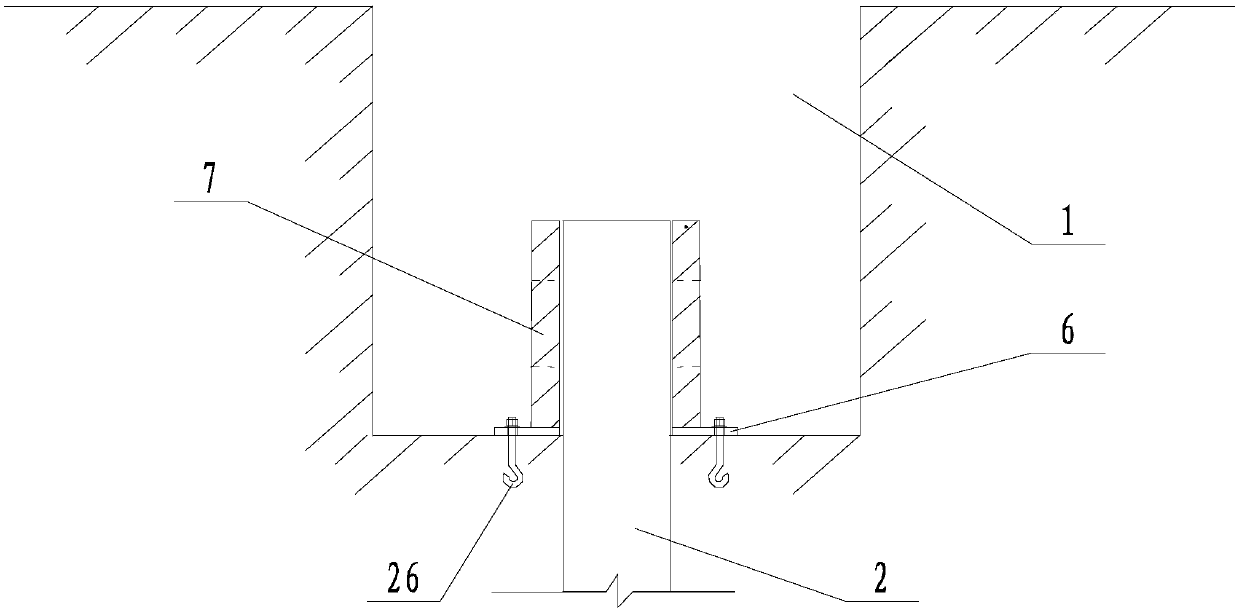

[0040] Such as Figure 1 to Figure 8 The installation structure of the deep well pump pipe in the civil air defense room of the comprehensive building is shown, and the installation structure of the deep well pump pipe in the civil air defense room of the comprehensive building includes the indoor pump pit 1, the deep water well 2 drilled in the pump pit 1, and the structure above the pump pit 1 The plate 3 and the water pump 5 are located in the deep well 2. The cable of the water pump 5 extends out of the pump pit 1 and is connected to the control box of the deep well pump. 4. Pass through the pump pit 1 and enter the deep water well 2. The bottom of the pump pipe 4 is connected to the water pump 5. The wellhead load-bearing frame is arranged in the pump pit 1. The wellhead load-bearing frame includes a first bottom plate 6 anchored at the bottom of the pump pit 1. The load-bearing bracket 7 is welded on the first bottom plate 6, and the load-bearing bracket 7 is used to car...

Embodiment 2

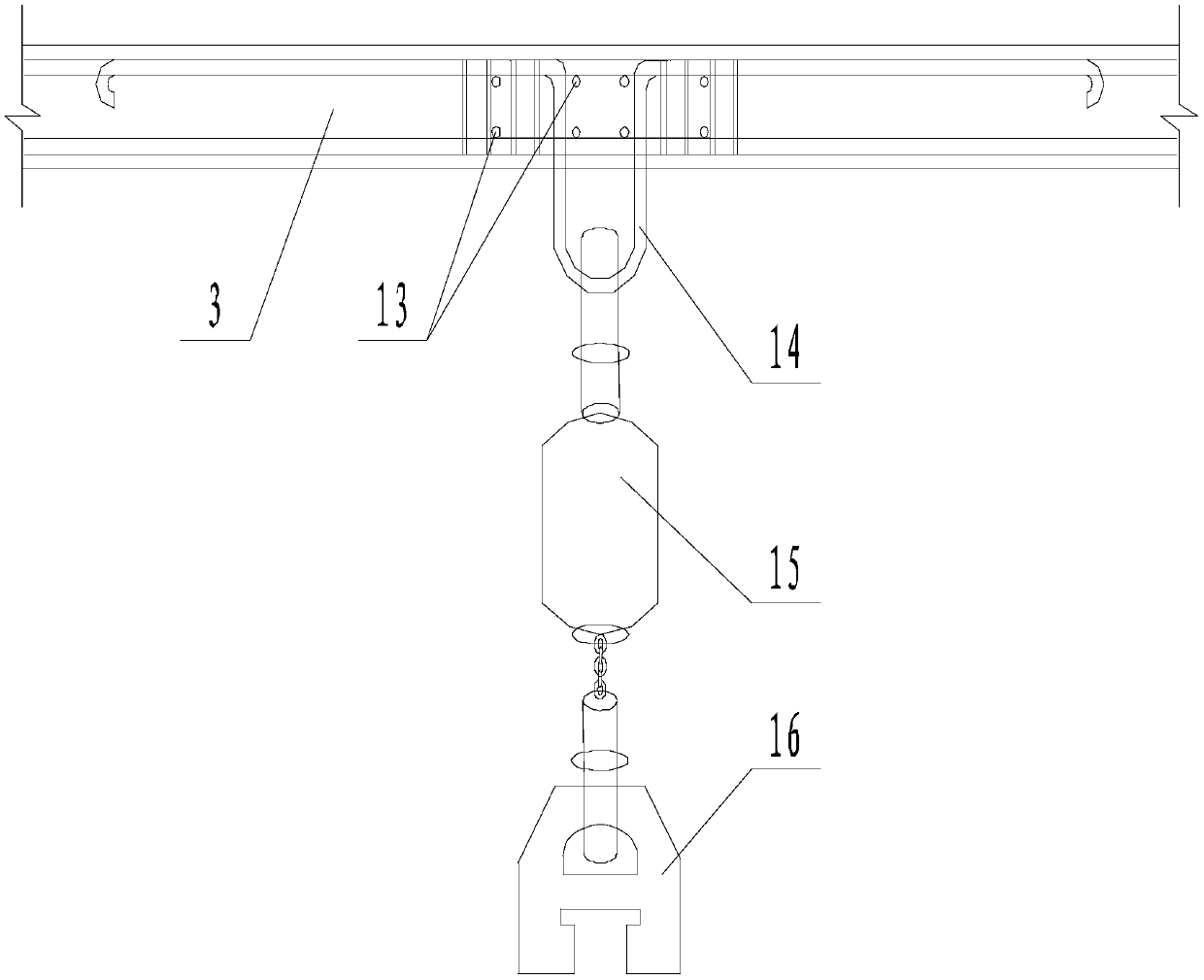

[0043] Such as Figure 1 to Figure 8 As shown, on the basis of Embodiment 1, the hoisting mechanism includes a hidden beam 13 arranged in the structural plate 3, the top end of the hook 14 is pre-buried above the hidden beam 13, and the bottom end of the hook 14 is in the shape of Arc shape, hook 14 is connected with hoist chain 15 , the bottom end of hoist chain 15 is connected with sling 16 , and the sling 16 is used for fixed connection with the top end of pump pipe 4 . The upper and lower ends of the pump pipe 4 are welded with flanges 17, and two adjacent pump pipes 4 are connected by flanges, and four flanges are welded between each flange 17 and the corresponding pump pipe 4. The ribs 18 uniformly distributed in the circumferential direction of the pump pipe 4 . The two flanges 17 between two adjacent sections of the pump pipe 4 are connected by flange bolts 19, and the flange bolts 19 pass through the two ends of the two flanges 17 and are sequentially inserted along ...

Embodiment 3

[0047] The installation method of the deep well pump pipe in the civil air defense room of a complex building comprises the following steps: (a) digging a pump pit 1 in the civil air defense room, drilling a deep water well 2 in the pump pit 1 to the design well depth, and placing the pump pipe on the structural plate 3 above the pump pit 1 A hoisting mechanism is provided to anchor the first bottom plate 6 to the bottom of the pump pit 1; (b) an anti-swing mechanism is set at the upper and lower ends of the water pump 5, and the anti-sway mechanism includes a ring clamp 11 sleeved on the outside of the water pump 5 , a number of leaf springs 12 are evenly distributed in the outer ring of the ring clamp 11, and the spring leaf 12 is arc-shaped, so that the concave surface of the spring leaf 12 faces the direction of the water pump 5; the water pump 5 with the anti-shake mechanism installed is connected to one end of the pump The pipe is lowered into the deep-water well 2 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com