Method for etching organic film and method for repairing display area circuit of display substrate

A technology for display substrates and organic films, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as speeding up the etching speed, and achieve the effect of speeding up the etching speed, ensuring the etching effect, and good etching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides an etching method for an organic film, which includes etching the position to be etched of the organic film through a focused ion beam, and during the etching process, the to-be-etched surface of the position to be etched of the organic film is into water vapor.

[0038] Wherein, the etching of the organic film is carried out in a real-time vacuum environment.

[0039] The high-energy focused ion beam can make the originally inactive water vapor active, and the active water vapor can react with the organic film to generate volatile substances, which can be pumped out with the real-time vacuum system during the etching process. Outside the etching environment, by injecting water vapor onto the surface to be etched during the process of etching the organic film by the focused ion beam, the position to be etched of the organic film can be etched quickly in a targeted manner, and during the etching process It does not cause etching damage to other ...

Embodiment 2

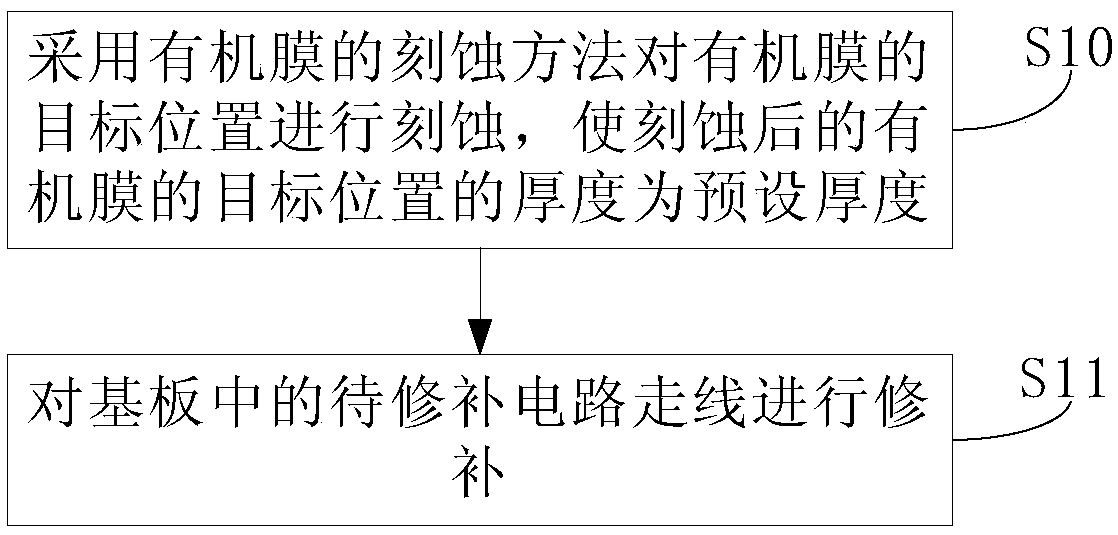

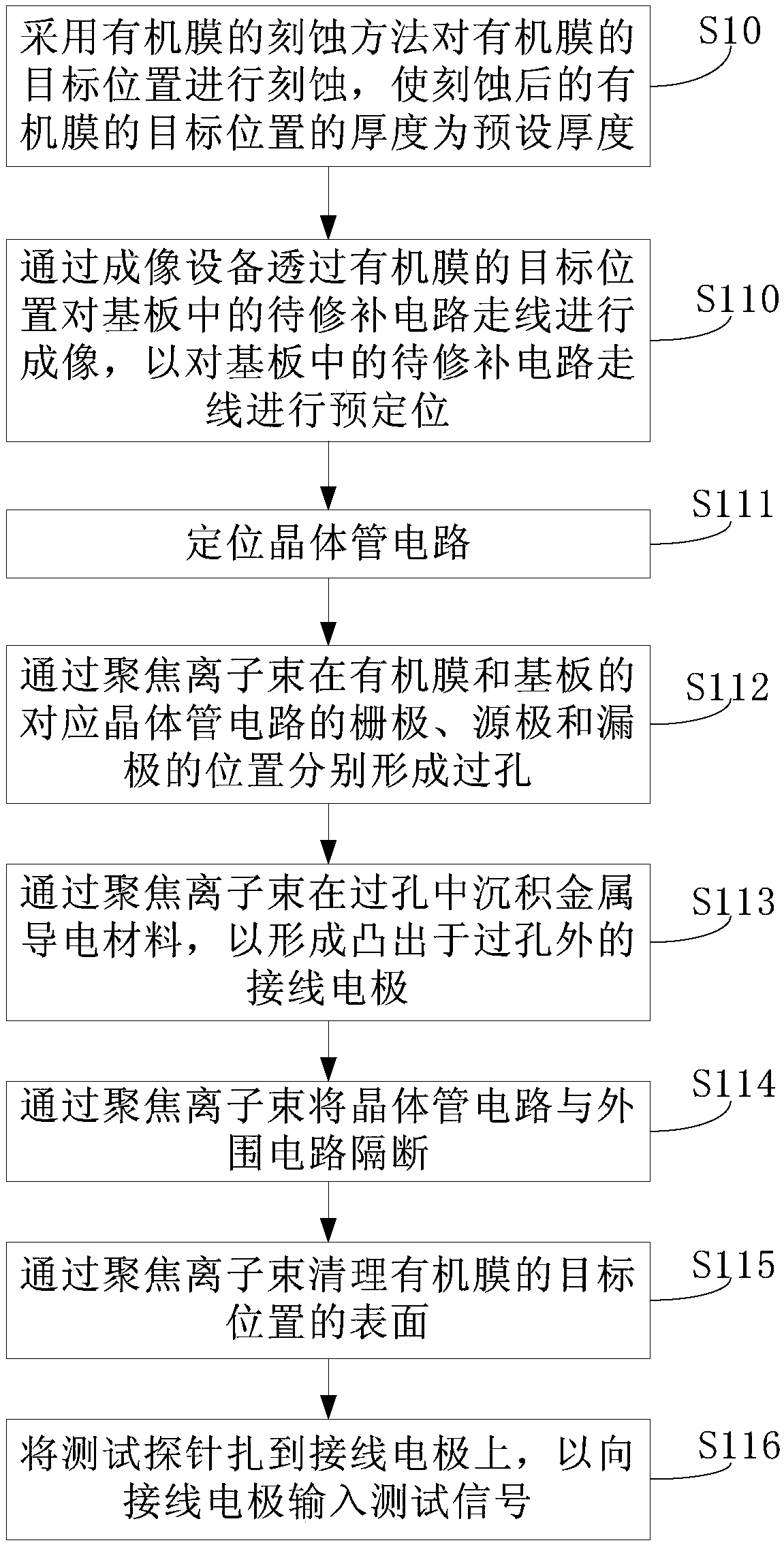

[0045] This embodiment provides a method for repairing the circuit in the display area of the display substrate. The display substrate includes a substrate and an organic film disposed on the substrate. The substrate is provided with circuit traces corresponding to the display area, and the organic film covers the circuit traces. for protection circuit traces, such as figure 1 and figure 2 As shown, the repairing method includes: Step S10: using the organic film etching method in Embodiment 1 to etch the target position of the organic film, so that the thickness of the target position of the organic film after etching is a preset thickness. Step S11: repairing the wiring of the circuit to be repaired in the substrate. The location of the circuit trace to be repaired corresponds to the location of the target location.

[0046] Wherein, the display substrate includes an organic electroluminescent display substrate. Repairing the circuit traces to be repaired in the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com