Sand sculpture based on MgO-MgSO4-H2O cementing material and preparation method of sand sculpture

A technology for cementing materials and sand sculptures, applied in the direction of climate change adaptation, etc., can solve the problems of prolonging the storage time of sand sculptures, no reports, and inability to move and transport sand sculpture handicrafts, so as to achieve easy long-term preservation and movement, low cost and easy preservation and the effect of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

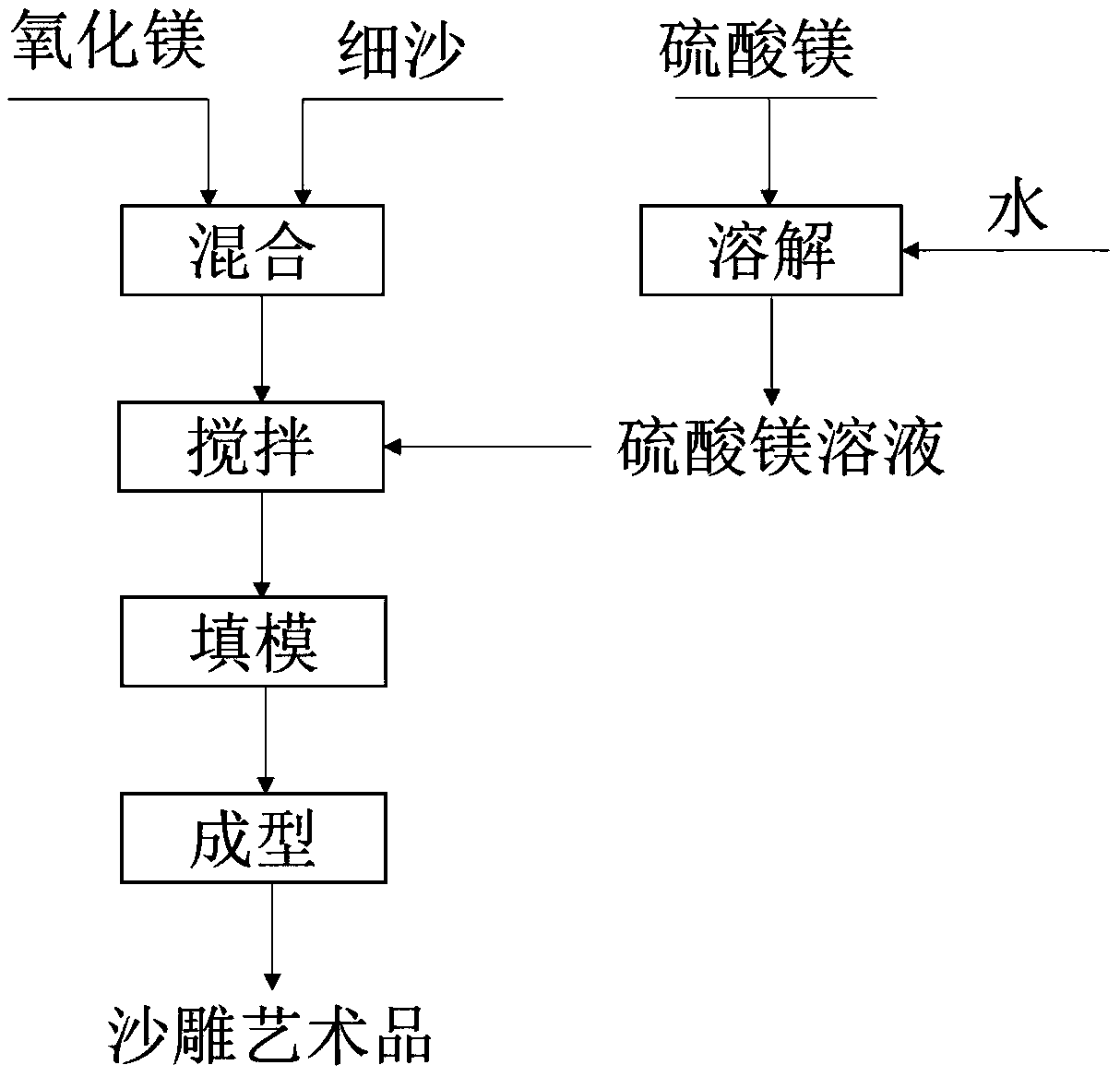

Method used

Image

Examples

Embodiment 1

[0044] 1. Get an appropriate amount of magnesium sulfate and dissolve it in water so that the concentration of the obtained magnesium sulfate solution is 25 degrees Baume.

[0045] 2. Take light-burned magnesia powder raw material (30kg) and desert fine sand (450kg) and mix evenly.

[0046] 3. Add magnesium sulfate solution (90kg) to the mixture in step 2, stir and mix to form MgO-MgSO 4 -H 2 O gelled sand mix.

[0047] 4. MgO-MgSO 4 -H 2 Fill the cemented sand mixture into the sand sculpture mold, tamp it firmly, and release it after 6 hours to become a durable sand sculpture.

Embodiment 2

[0049] 1. Get an appropriate amount of magnesium sulfate and dissolve it in water so that the concentration of the obtained magnesium sulfate solution is 15 degrees Baume.

[0050] 2. Take caustic dolomite powder magnesium oxide raw material (30kg) and desert fine sand (300kg) and mix evenly.

[0051] 3. Add magnesium sulfate solution (60kg) to the mixture in step 2, stir and mix to form MgO-MgSO 4 -H 2 O gelled sand mix.

[0052] 4. MgO-MgSO 4 -H 2 Fill the cemented sand mixture into the sand sculpture mold, tamp it firmly, and release it after 8 hours to become a durable sand sculpture.

Embodiment 3

[0054] 1. Get an appropriate amount of magnesium sulfate and dissolve it in water so that the concentration of the obtained magnesium sulfate solution is 35 degrees Baume.

[0055] 2. Take light-burned magnesia powder raw material (30kg) and desert fine sand (600kg) and mix evenly.

[0056] 3. Add magnesium sulfate solution (60kg) and coagulant to the mixture in step 2, stir and mix to form MgO-MgSO 4 -H 2 O gelled sand mix.

[0057] 4. MgO-MgSO 4 -H 2 Fill the cemented sand mixture into the sand sculpture mold, tamp it firmly, and release it after 6 hours to become a durable sand sculpture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com