Manufacturing process of high-adhesion polyurethane automobile instrument panel

A technology of automobile dashboard and manufacturing process, which is applied in the field of polymers, can solve the problems of high maintenance costs and expensive instrument panels, and achieve the effects of improving bonding performance, reducing storage, and avoiding production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

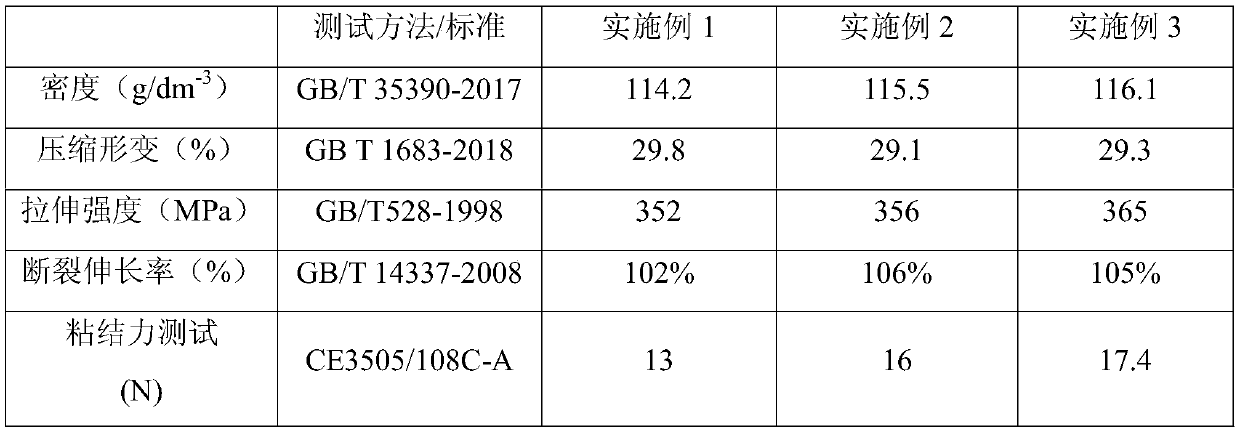

Examples

Embodiment 1

[0026] ① Preparation of material A: Add 0.1kg of N,N-dimethylcyclohexylamine to 80kg of CHP-2045 polyether polyol of Changhua Company, add 2kg of water, and add 1kg of LX0801 polyether silicone oil of Longxu Chemical Industry , add 10kg of propylene glycol, control the speed at 80 rpm, and stir at room temperature for 60 minutes to obtain material A;

[0027] ②Preparation of material B: Prepare 70kg of Wanhua’s MDI-50, 30kg from Wanhua Company 6928 Put each component in a reaction kettle, stir for 40 minutes at room temperature, and control the speed at 50 rpm to obtain material B, and keep it sealed;

[0028] ③Preparation of raw materials: Put material A into the raw material barrel of group A of the foaming machine; put material B into the raw material barrel of group B of the foaming machine;

[0029] ④Preparation of instrument panel shell: Spread the leather on the bottom of the mould, use a foaming machine to mix material A and material B evenly in the mixing area of ...

Embodiment 2

[0032] ① Preparation of material A: Add 20kg of Huada polyester polyol to 60kg of Changhua CHP-2045 polyether polyol, add 0.1kg of N,N-dimethylcyclohexylamine, add 2kg of water, add 1kg Add 10kg of propylene glycol to LX0801 polyether silicone oil of Longxu Chemical Industry Co., Ltd., control the rotation speed at 80 rpm, and stir at room temperature for 60 minutes to obtain material A;

[0033] ②Preparation of material B: Prepare 70kg of Wanhua’s MDI-50, 30kg from Wanhua Company 6928 Put each component in a reaction kettle, stir for 40 minutes at room temperature, and control the speed at 50 rpm to obtain material B, and keep it sealed;

[0034] ③Preparation of raw materials: Put material A into the raw material barrel of group A of the foaming machine; put material B into the raw material barrel of group B of the foaming machine;

[0035] ④Preparation of instrument panel shell: Spread the leather on the bottom of the mould, use a foaming machine to mix material A and ma...

Embodiment 3

[0038] ① Preparation of material A: Add 10kg of Huada polyester polyol to 80kg of Changhua CHP-2045 polyether polyol, add 0.1kg of N,N-dimethylcyclohexylamine, add 0.1kg of triethyl Amine, add 2kg of water, add 0.8kg of Jiaxing Kerui Silicone Co., Ltd. 106 hydroxy silicone oil, add 0.2kg of Longxu Chemical LX0801 polyether silicone oil, add 8kg of ethylene glycol, 7kg of propylene glycol, and control the speed at 40~ 80 revs / min, stirring at room temperature for 40-60 minutes, you can get material A;

[0039] ②Preparation of material B: prepare 60kg of Wanhua’s MDI-50, prepare 40kg from Wanhua Company 6928. Put each component in the reaction kettle, stir at room temperature for 40 minutes, and control the speed at 30-50 rpm, and then obtain material B, which is sealed and stored;

[0040] ③Preparation of raw materials: Put material A into the raw material barrel of group A of the foaming machine; put material B into the raw material barrel of group B of the foaming machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com